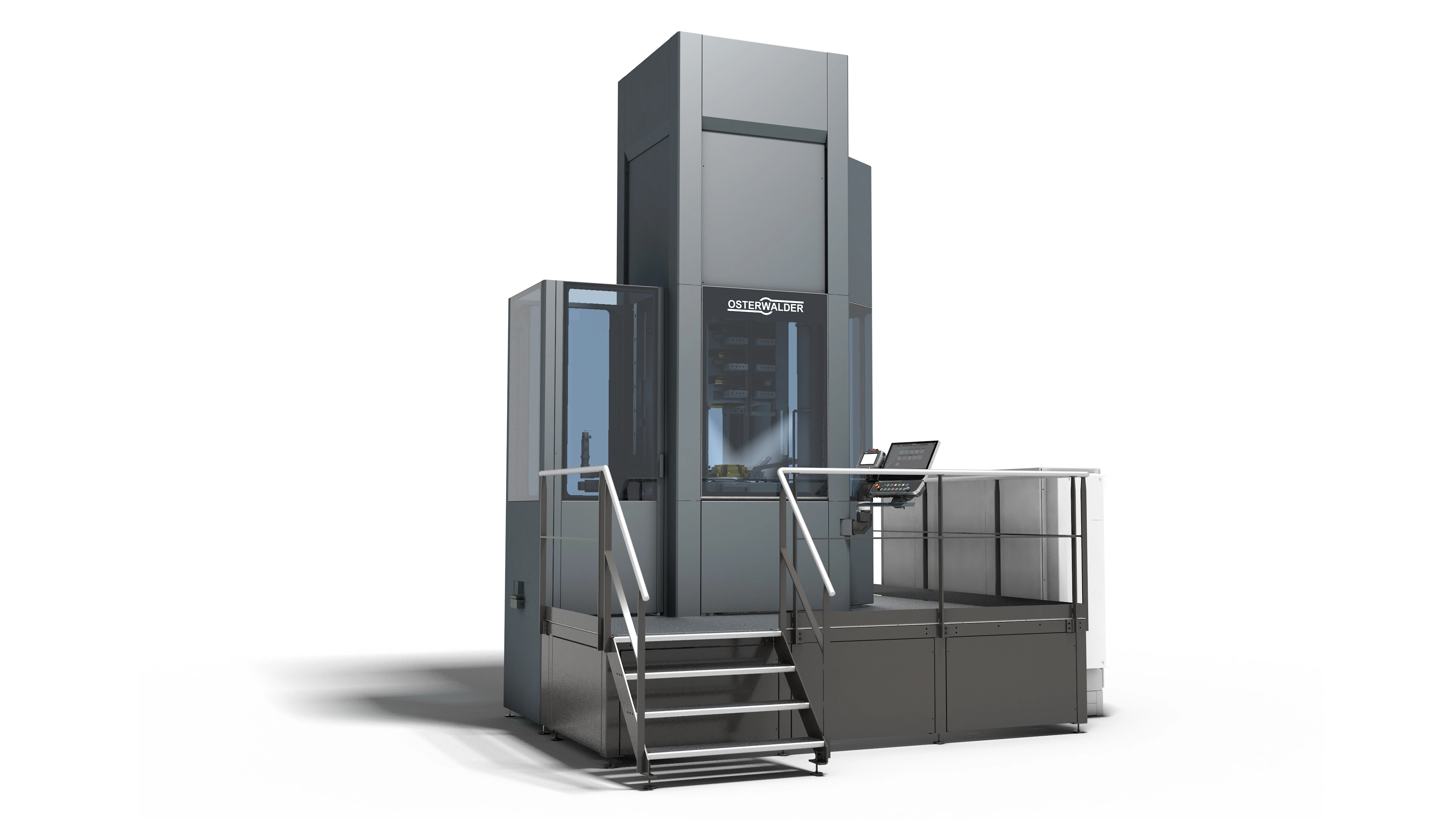

Reference Project

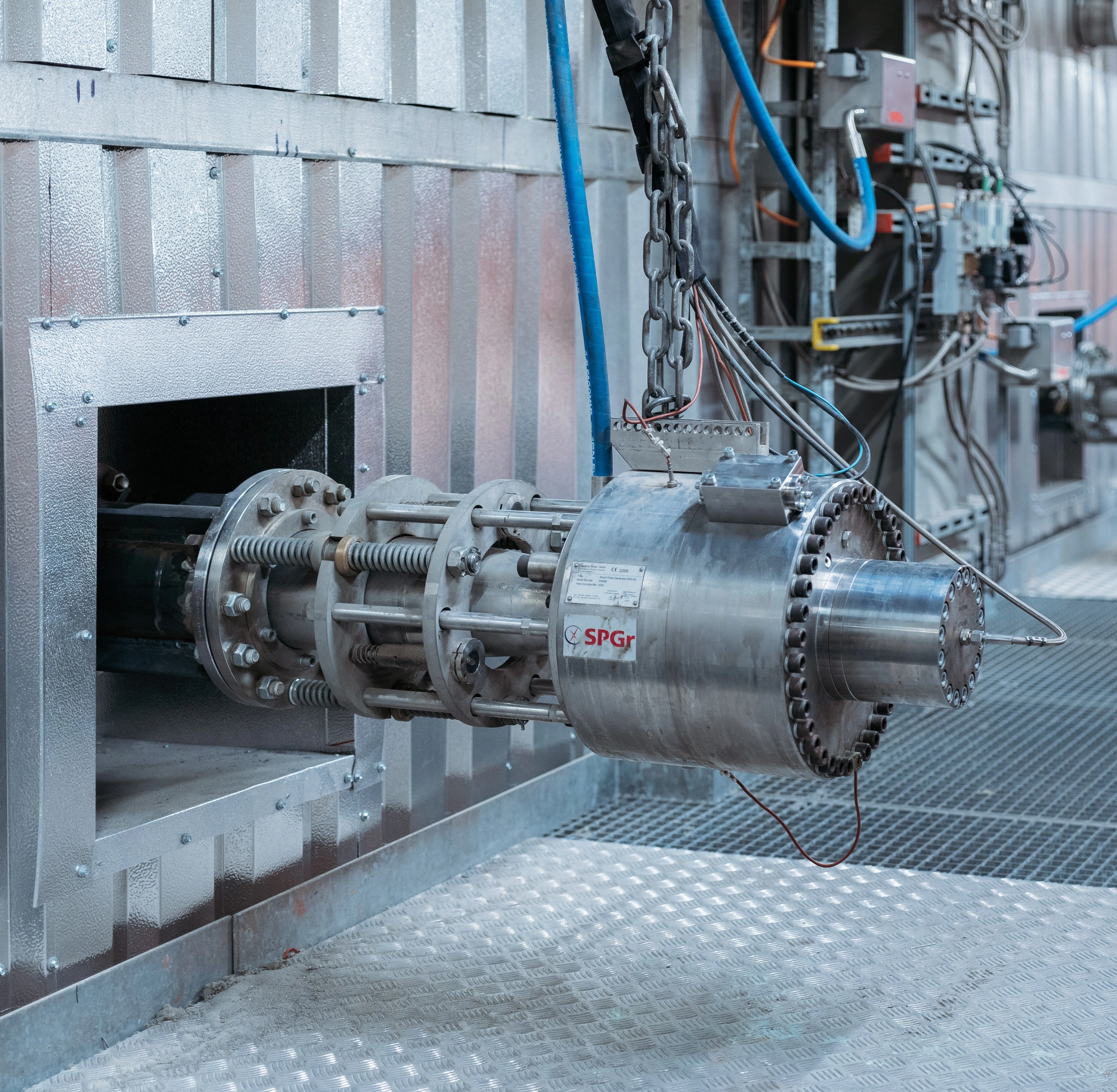

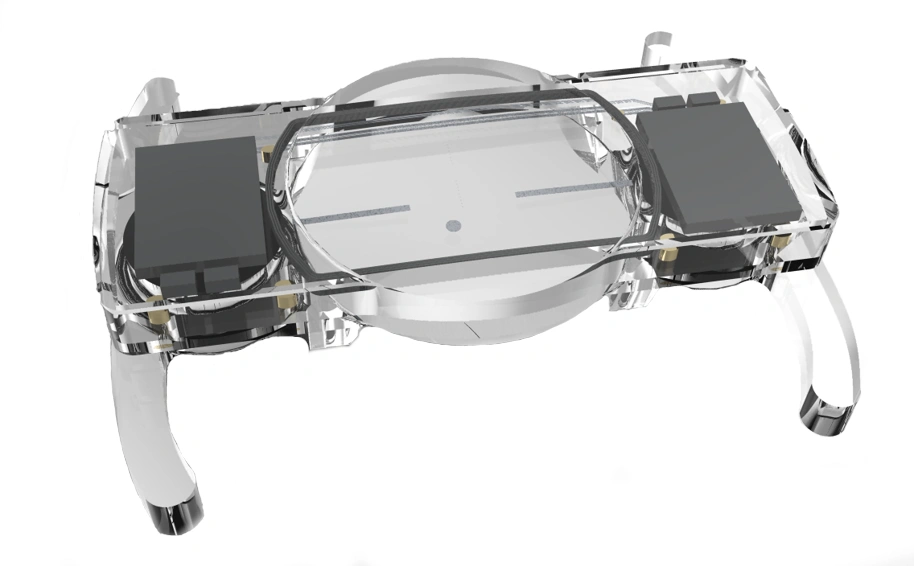

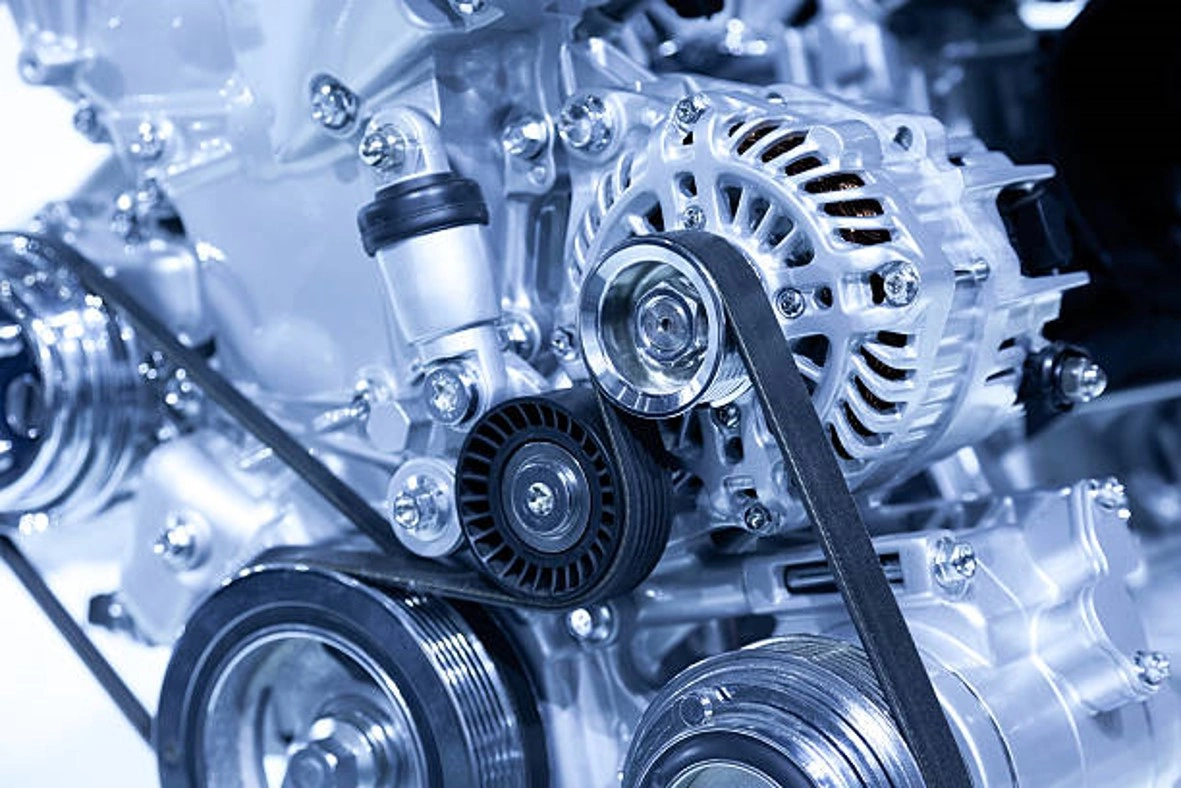

Thermoelectric Generator (TEG) for Recovering Heat Energy from Diesel Motor Exhaust

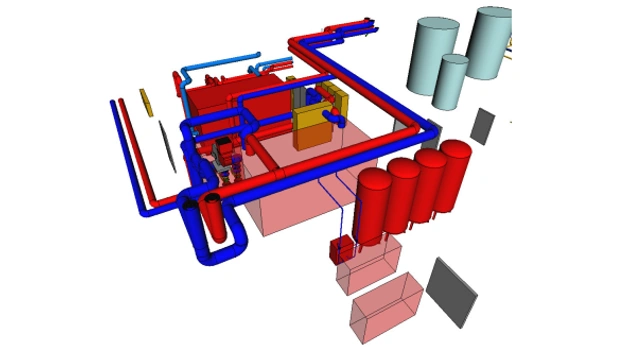

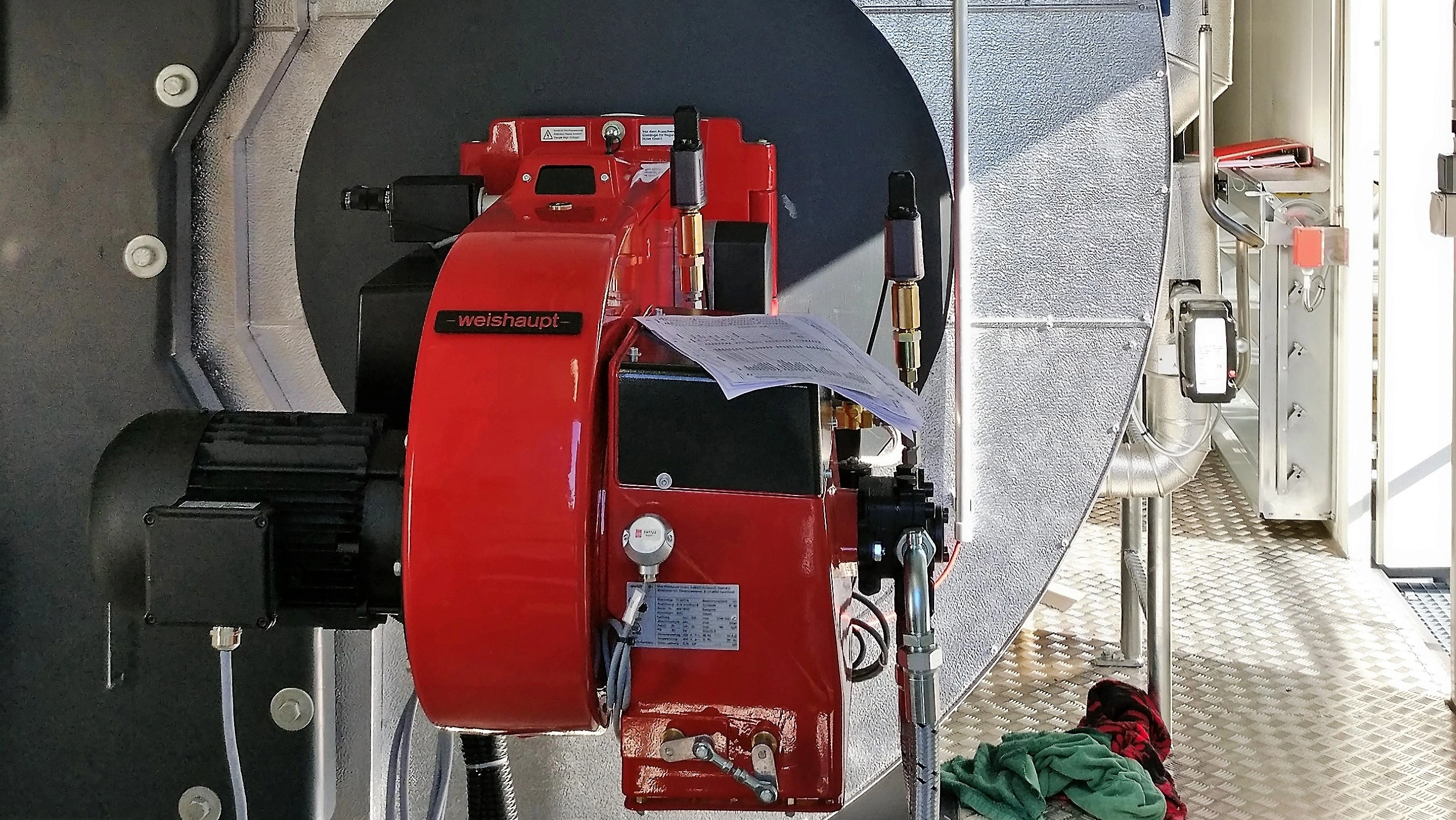

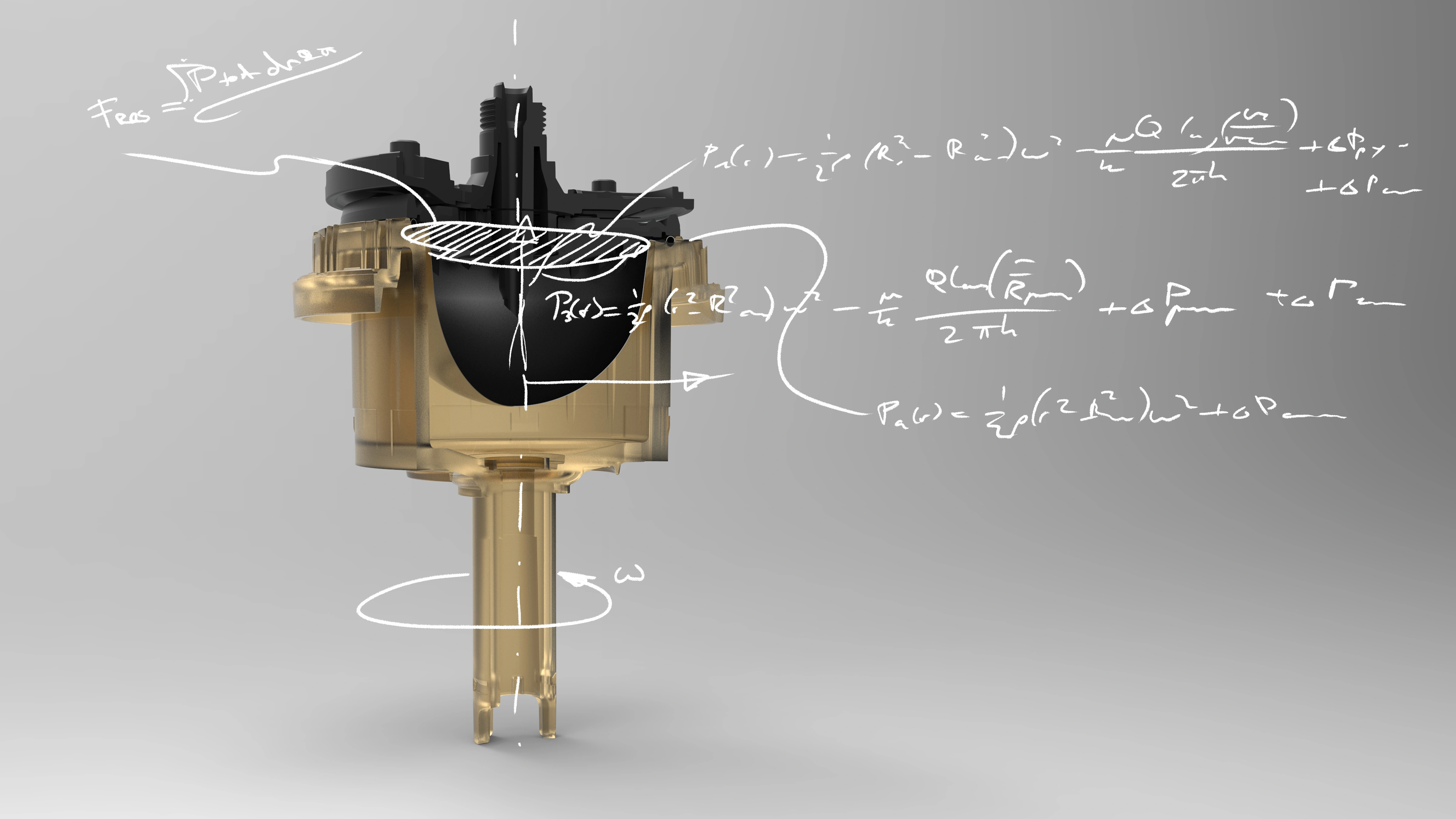

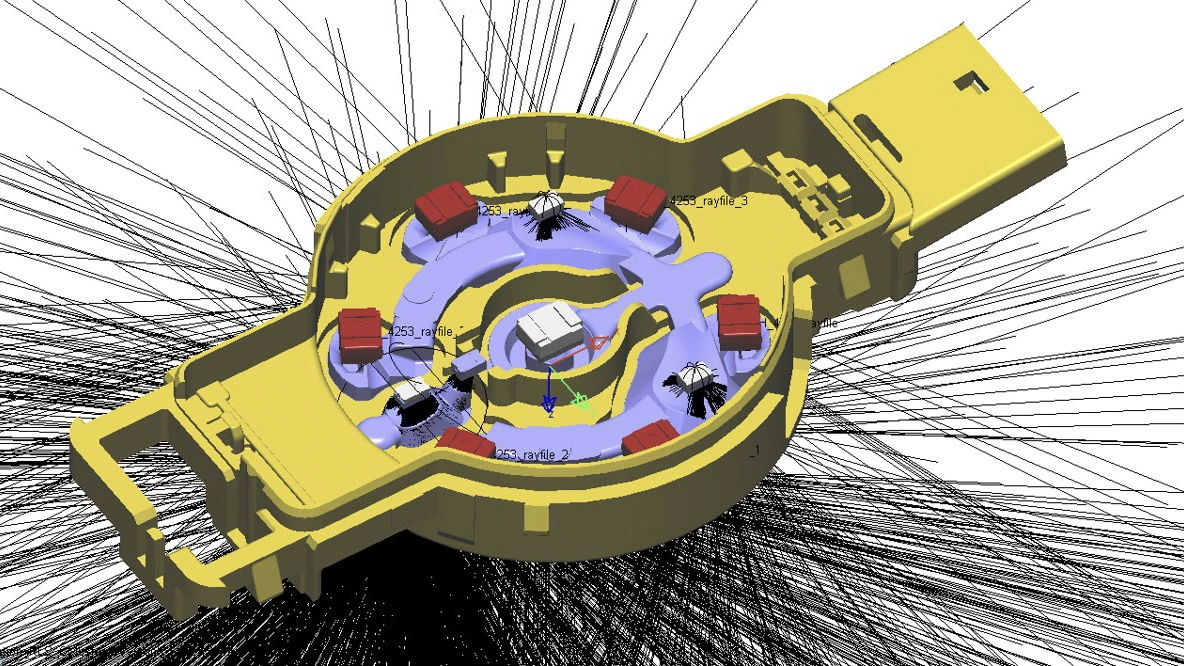

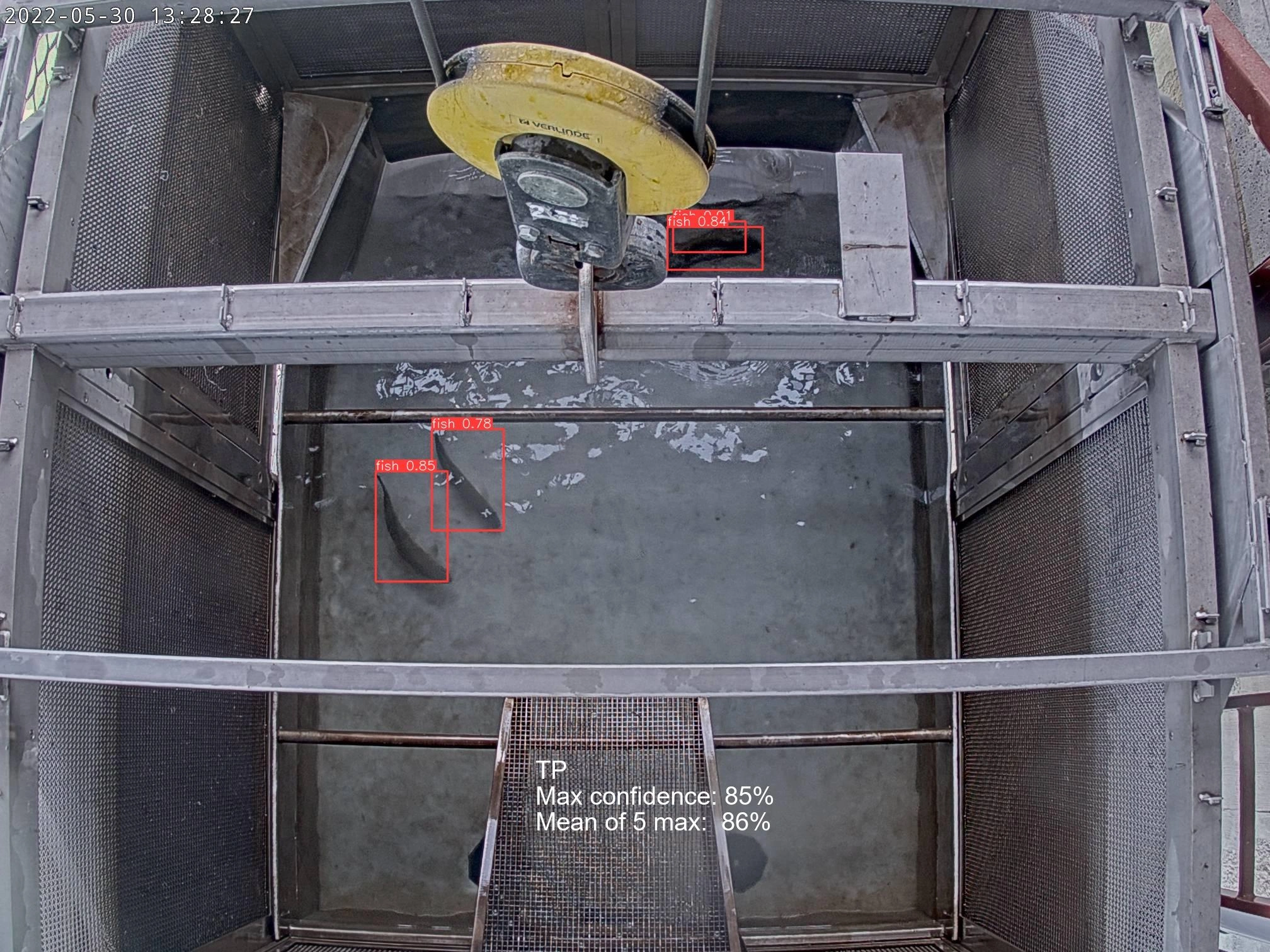

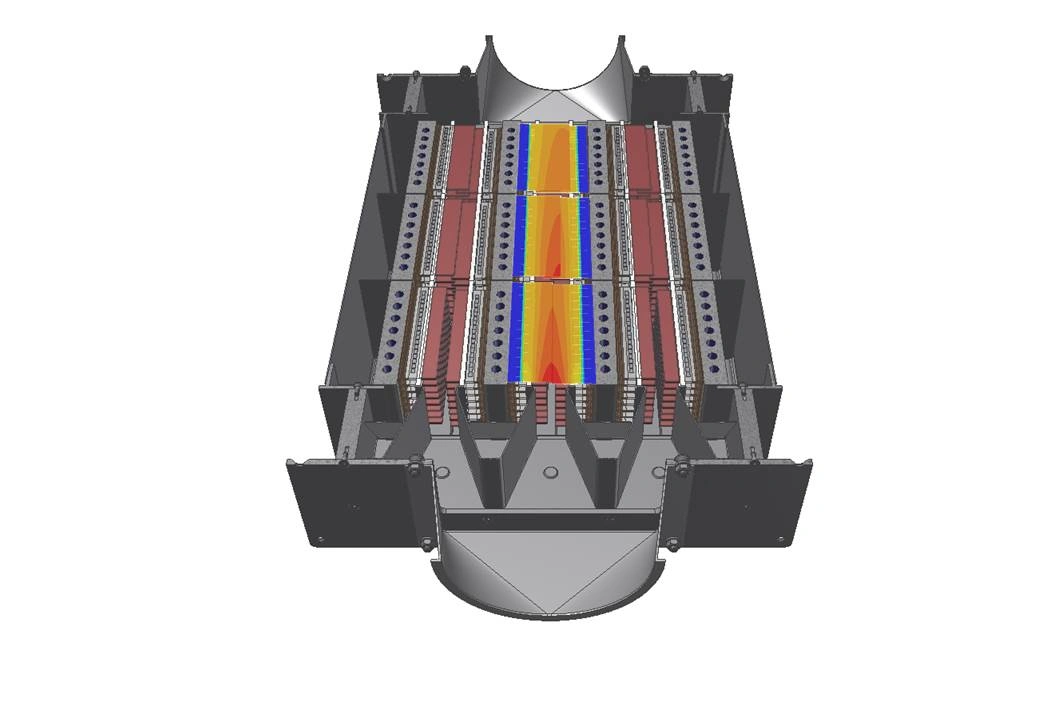

A thermoelectric generator (TEG) is capable of transforming heat flows into electrical power. Helbling developed a TEG for a diesel-electric locomotive for Bombardier Transportation from start to finish, from the initial product idea through to a demo locomotive on a 1:1 scale.

The question of how to effectively convert temperature differentials into power is one that researchers and several branches of industry have been working on for some time now. One of these is the rail vehicle industry. To this end, global market leader Bombardier Transportation approached Helbling with the idea of developing a thermoelectric energy recovery system and asked for a computational feasibility study. This was followed up with an order to develop several fundamental system concepts, and to devise and commission a breadboard simulator. Within the scope of this challenging project, Helbling's greatest strength was its network of excellence, which allowed it to integrate employees from a wide range of different fields into the team, even at extremely short notice where necessary. Furthermore, since Helbling was an external service provider and not involved in day-to-day business, such as production order placement, it could concentrate fully on the R&D project at hand. Other key criteria included Helbling's extensive expertise and many years of experience in the development of rail vehicle components.

The question of how to effectively convert temperature differentials into power is one that researchers and several branches of industry have been working on for some time now. One of these is the rail vehicle industry. To this end, global market leader Bombardier Transportation approached Helbling with the idea of developing a thermoelectric energy recovery system and asked for a computational feasibility study. This was followed up with an order to develop several fundamental system concepts, and to devise and commission a breadboard simulator. Within the scope of this challenging project, Helbling's greatest strength was its network of excellence, which allowed it to integrate employees from a wide range of different fields into the team, even at extremely short notice where necessary. Furthermore, since Helbling was an external service provider and not involved in day-to-day business, such as production order placement, it could concentrate fully on the R&D project at hand. Other key criteria included Helbling's extensive expertise and many years of experience in the development of rail vehicle components.

Key Figures

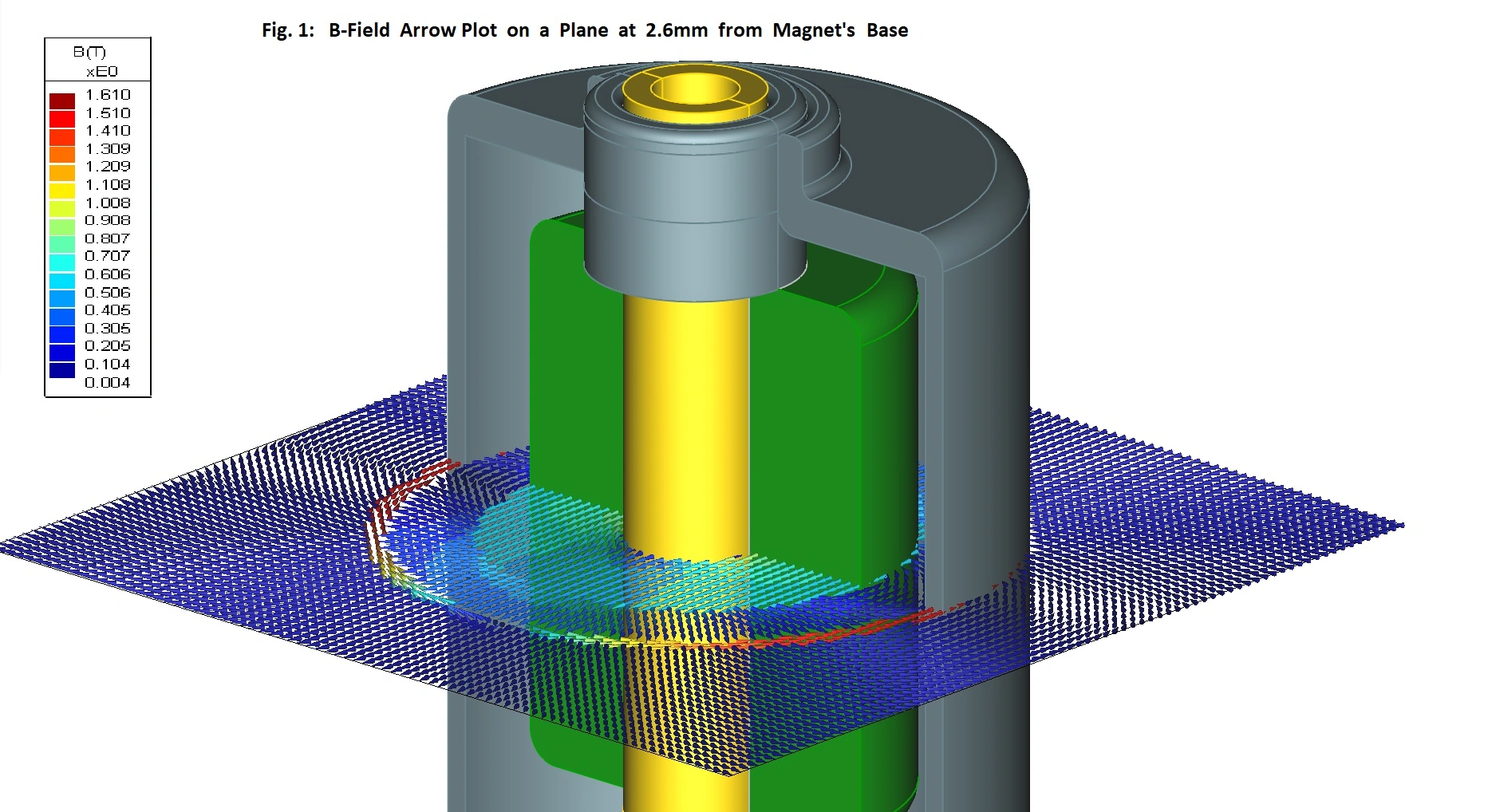

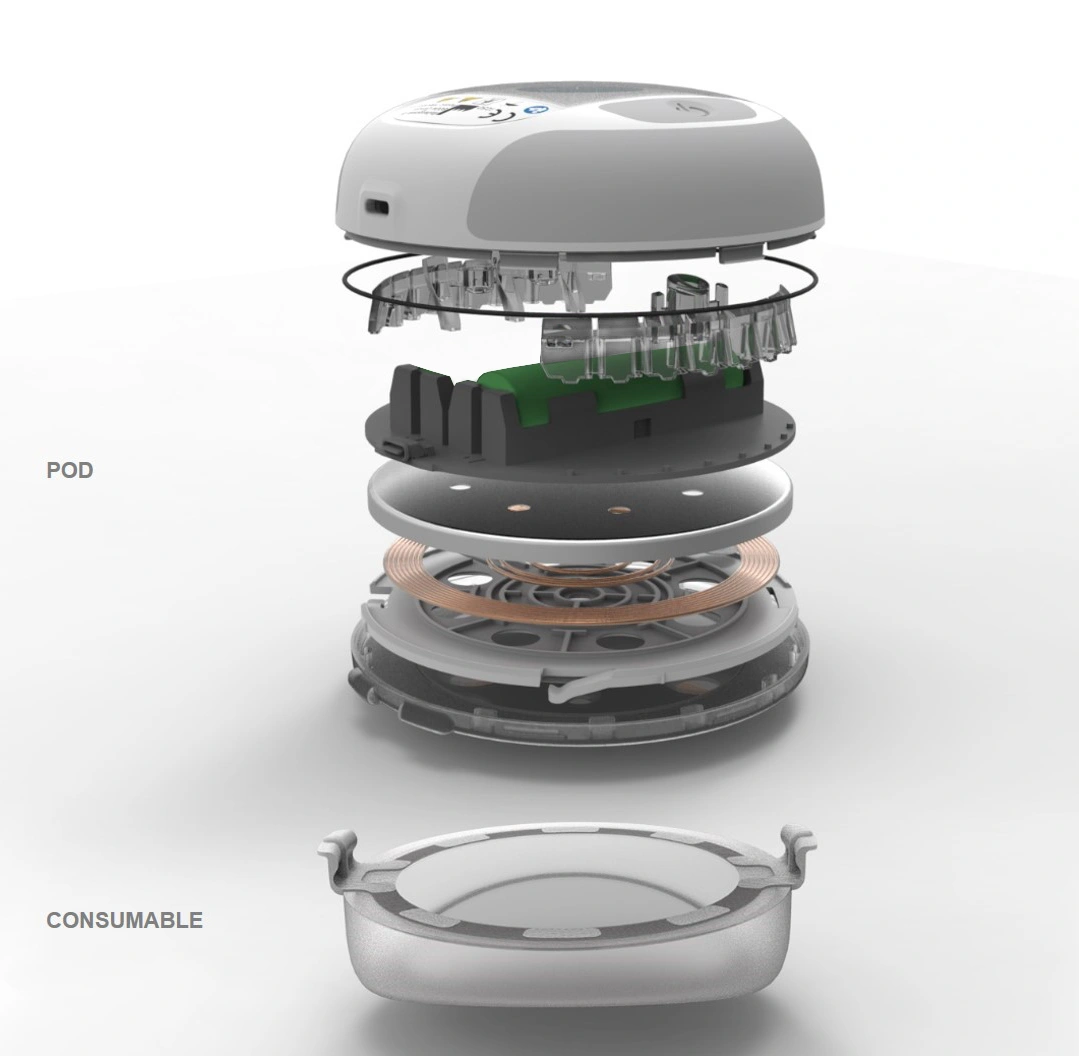

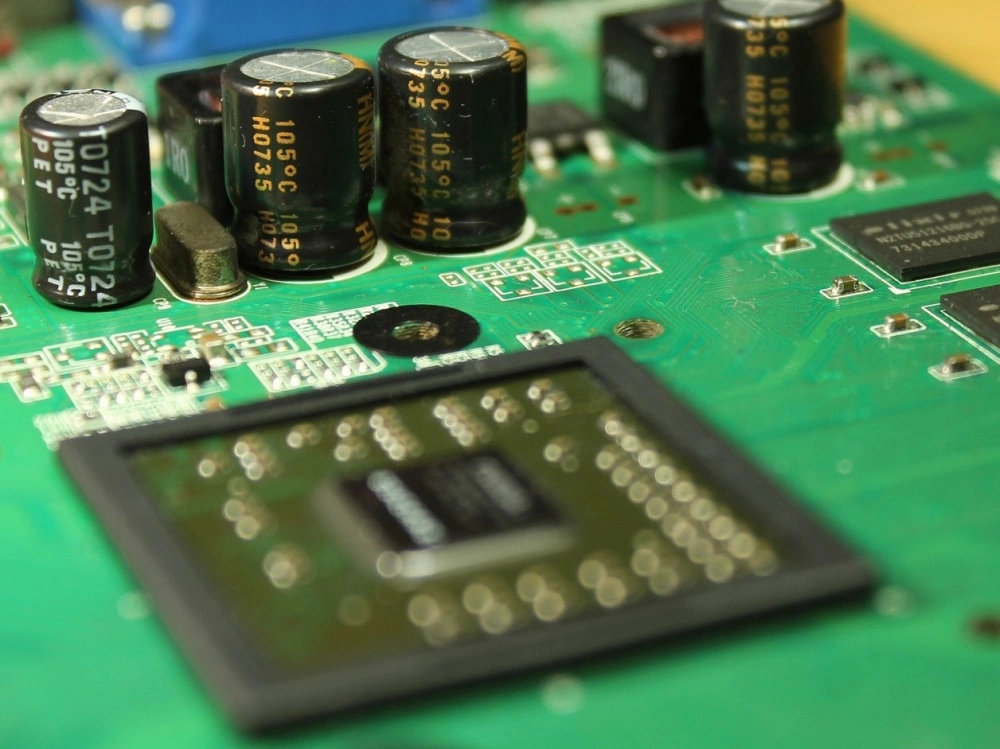

- The TEG employs thin-film semiconductor technology to generate an electrical voltage from temperature differences (reversal of the Peltier element or Seebeck effect).

- The TEG's semiconductor modules were developed by O-Flexx Technologies GmbH, a partner company of Bombardier Transportation. The technology applied in these modules not only allows for considerably higher power densities than previous thermoelectric modules, but also cuts the cost of materials and production.

- The TEG is expected to help cut diesel usage by 3 % – 5 %.

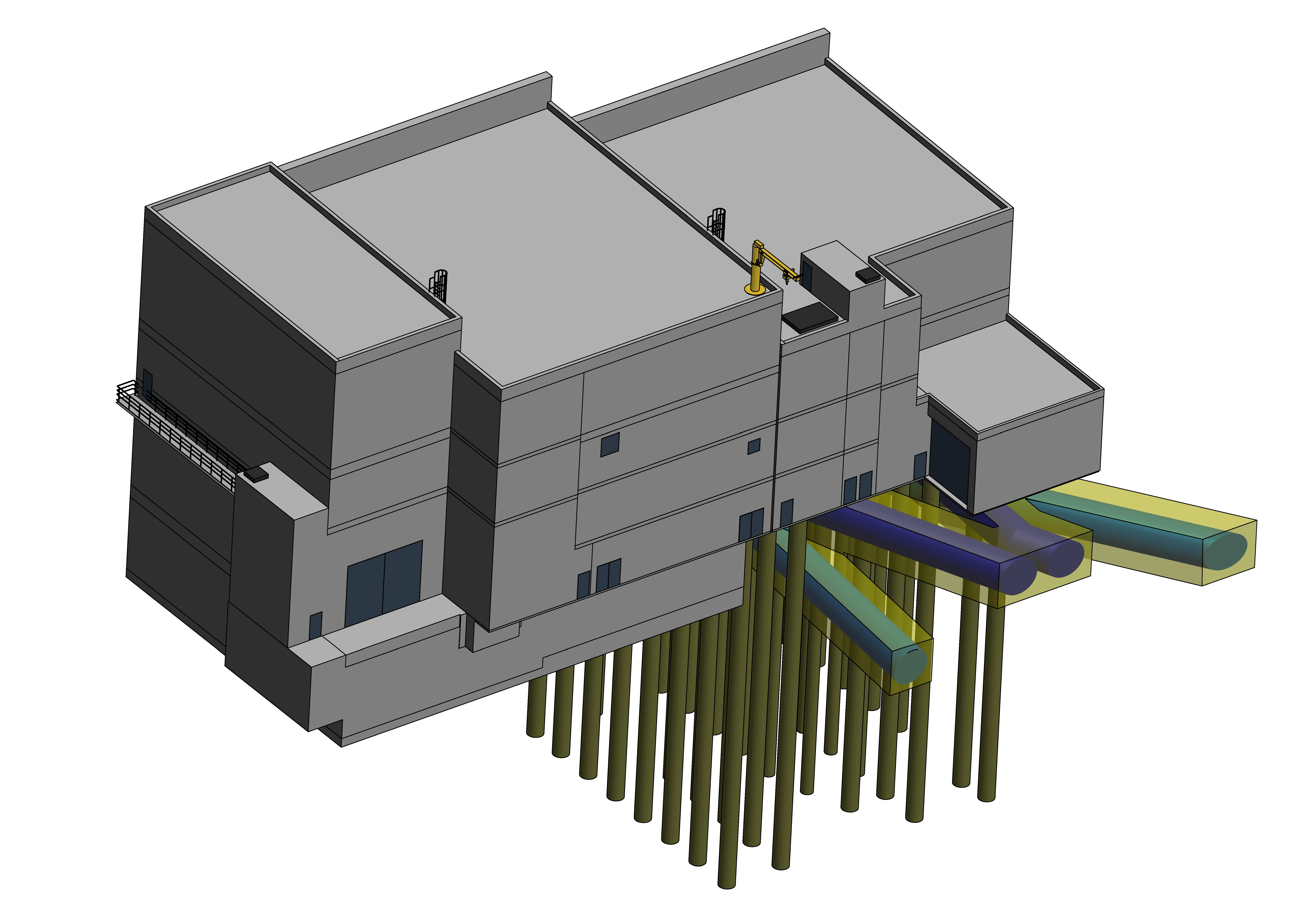

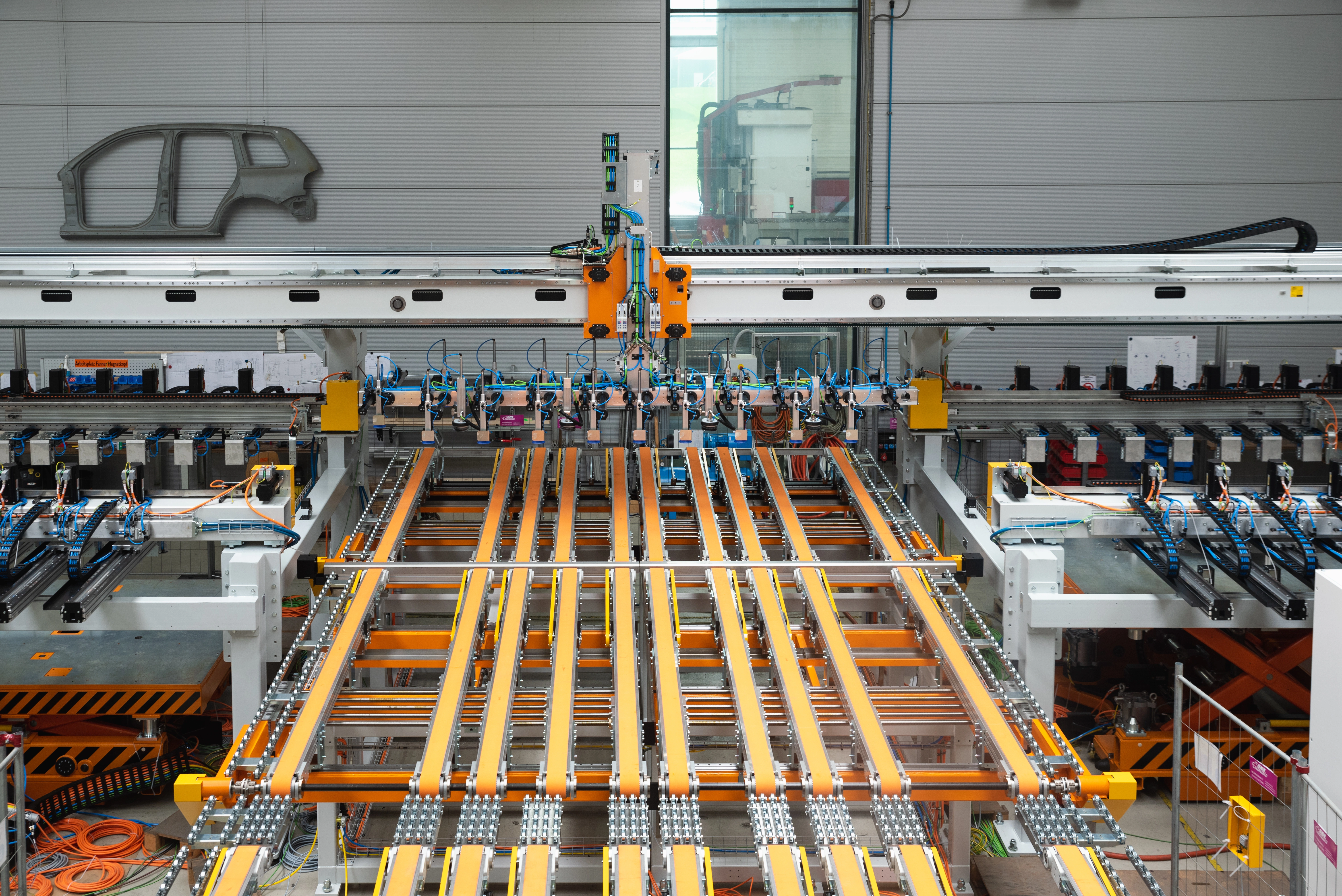

- The TEG is installed in the exhaust stream in place of the muffler. Its dimensions are predefined.

- The TEG system must not make the locomotive significantly heavier.

Our Contribution

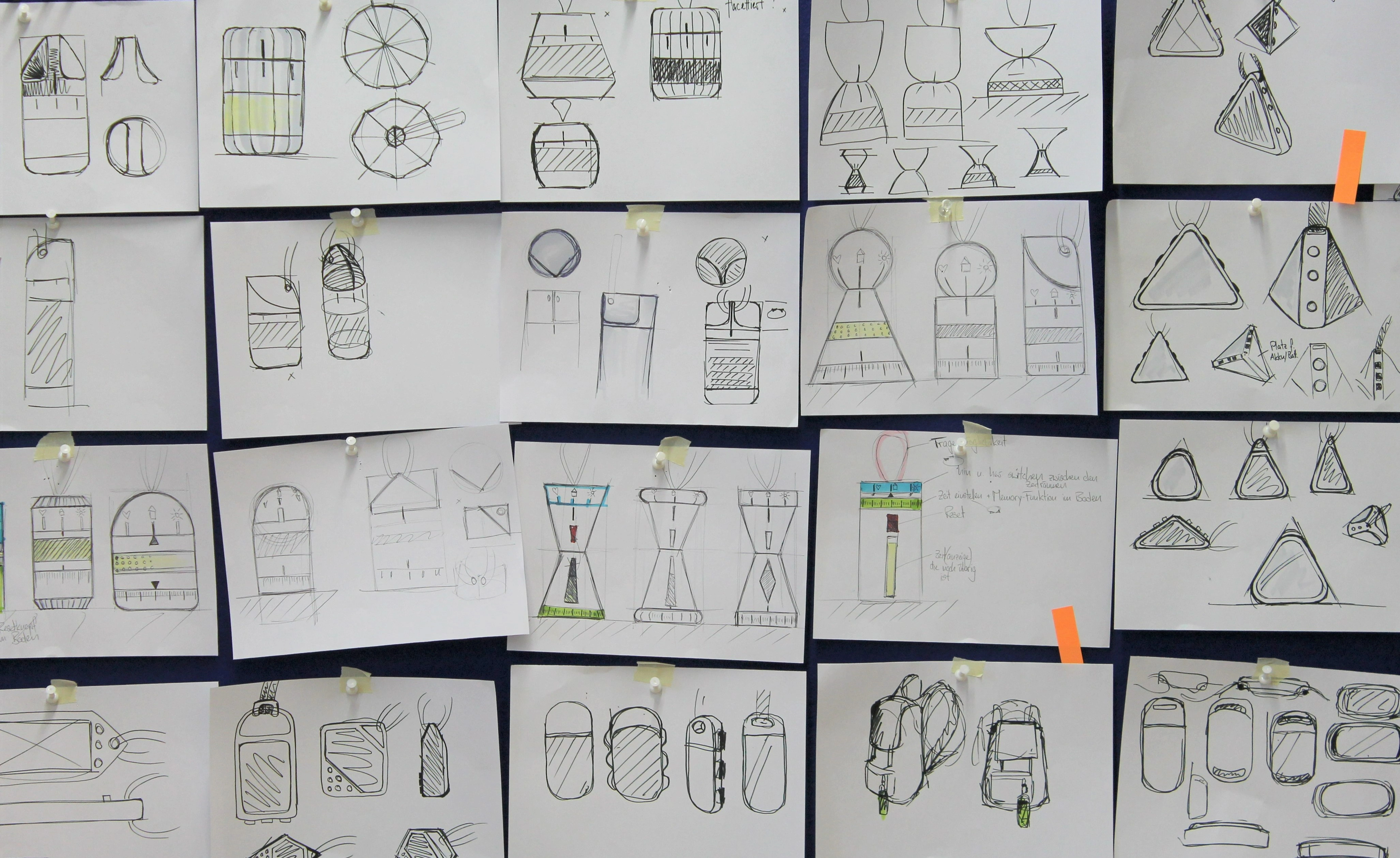

- Pilot and feasibility studies to evaluate various system ideas

- Questions whether heat exchanger can be directly installed or whether intermediate circuits in external heat exchanger are needed

- Production, evaluation and identification of variants

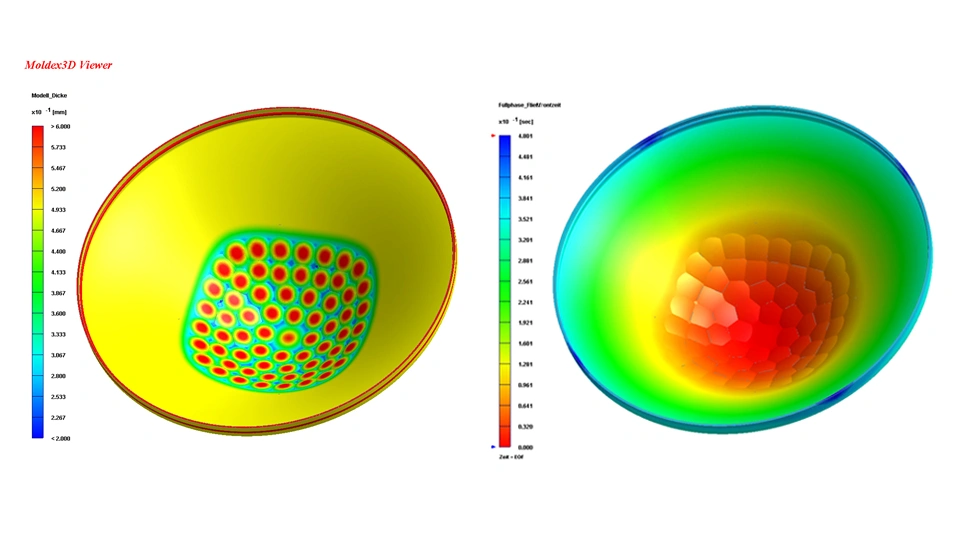

- Concepts for functional model and detailed calculations for evaluating various fundamental system approaches

- Specification of solution in an iterative process

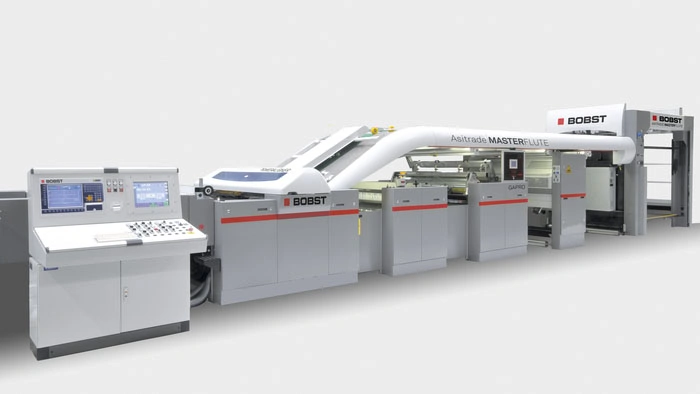

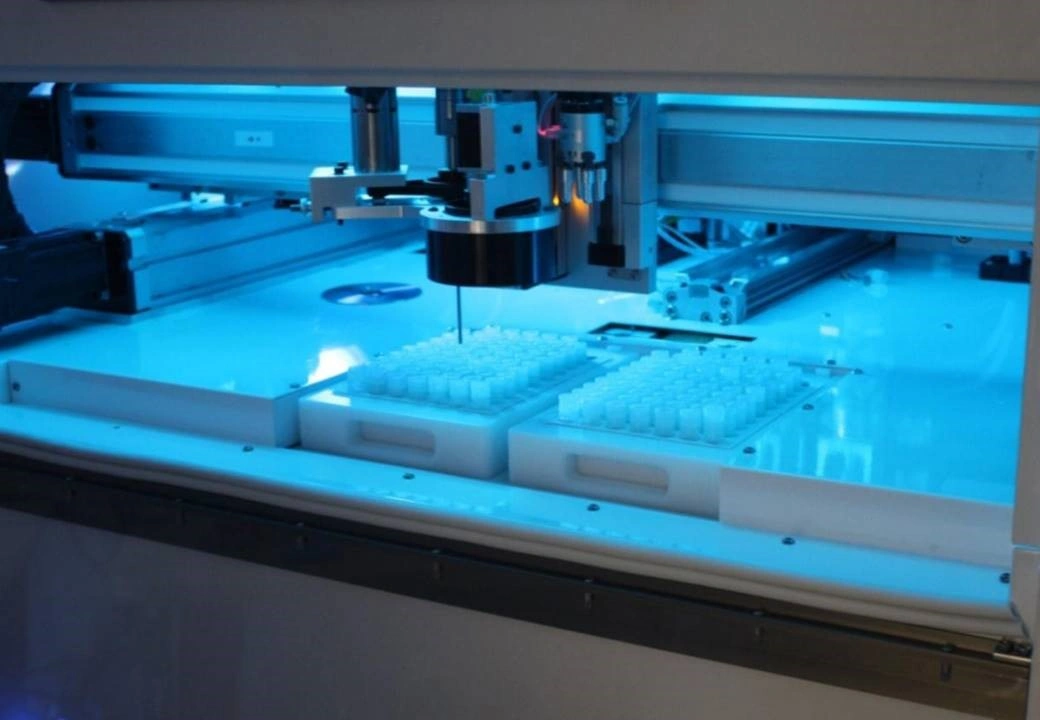

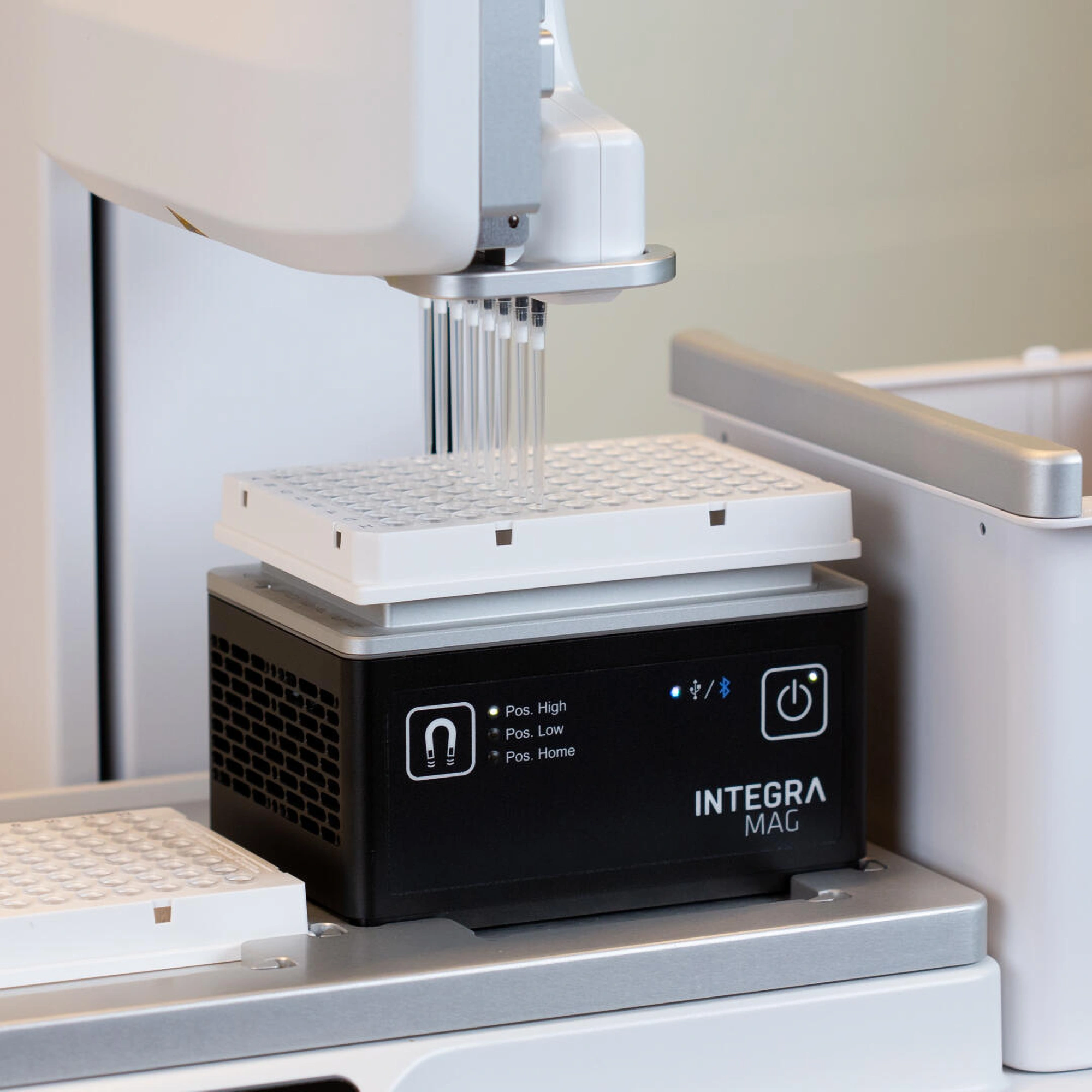

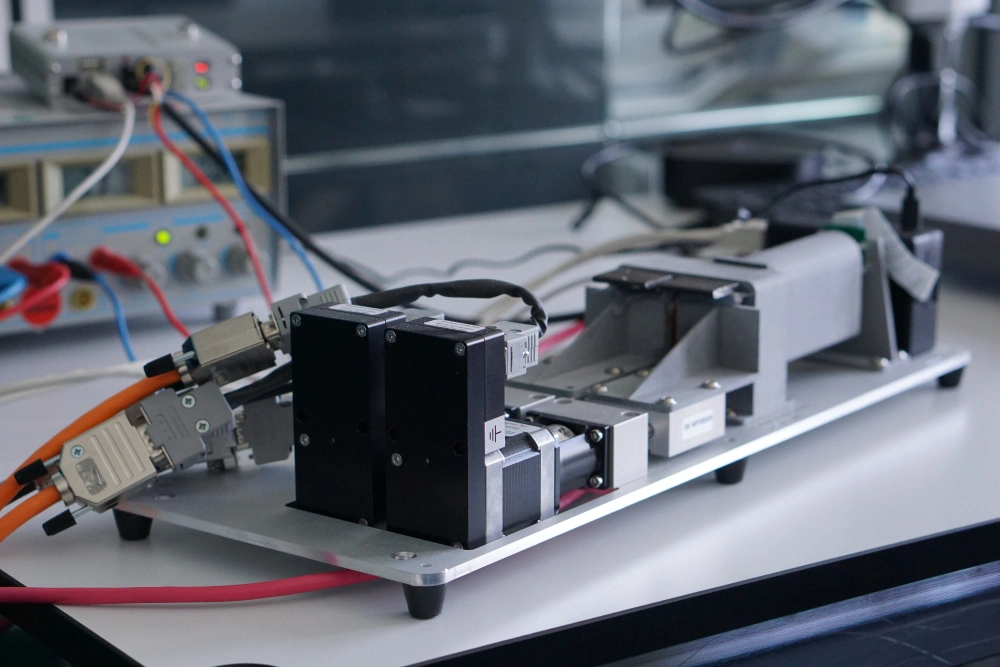

- Developing, constructing and commissioning laboratory demonstrator

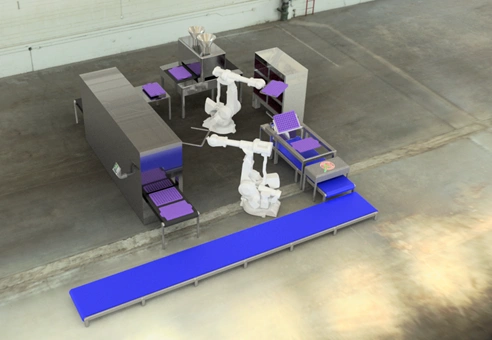

- Developing TEG demonstrator in 1:1 locomotive scale

- Parallel approach for use on diesel electric locomotive

Outcome

The TEG system was the topic of two conference papers:

Heghmanns, K. Geradts, G. Barthelmes, M. Beitelschmidt: Ein thermoelektrisches Generatorsystem zur Abwärmenutzung in dieselelektrischen Fahrzeugen (A thermoelectric generator system for waste heat usage in diesel-electric vehicles); 3rd IAV Thermoelectrics Conference, Berlin, November 21–23, 2012

G. Barthelmes, K. Geradts: Konzipierung eines Miniatur-Prototypen für einen Thermoelektrischen Generator (Concept development of a miniature prototype for a thermo-electric generator); NAFEMS seminar "Concept Design Driven by Simulation", Wiesbaden, March 21, 2013

A patent application is being prepared for the TEG's integration into the waste heat exchanger.

Contact

Cases

Internationales Unternehmen der Papierindustrie – Analyse des Dampfsystems

Industries:

Services:

Cases

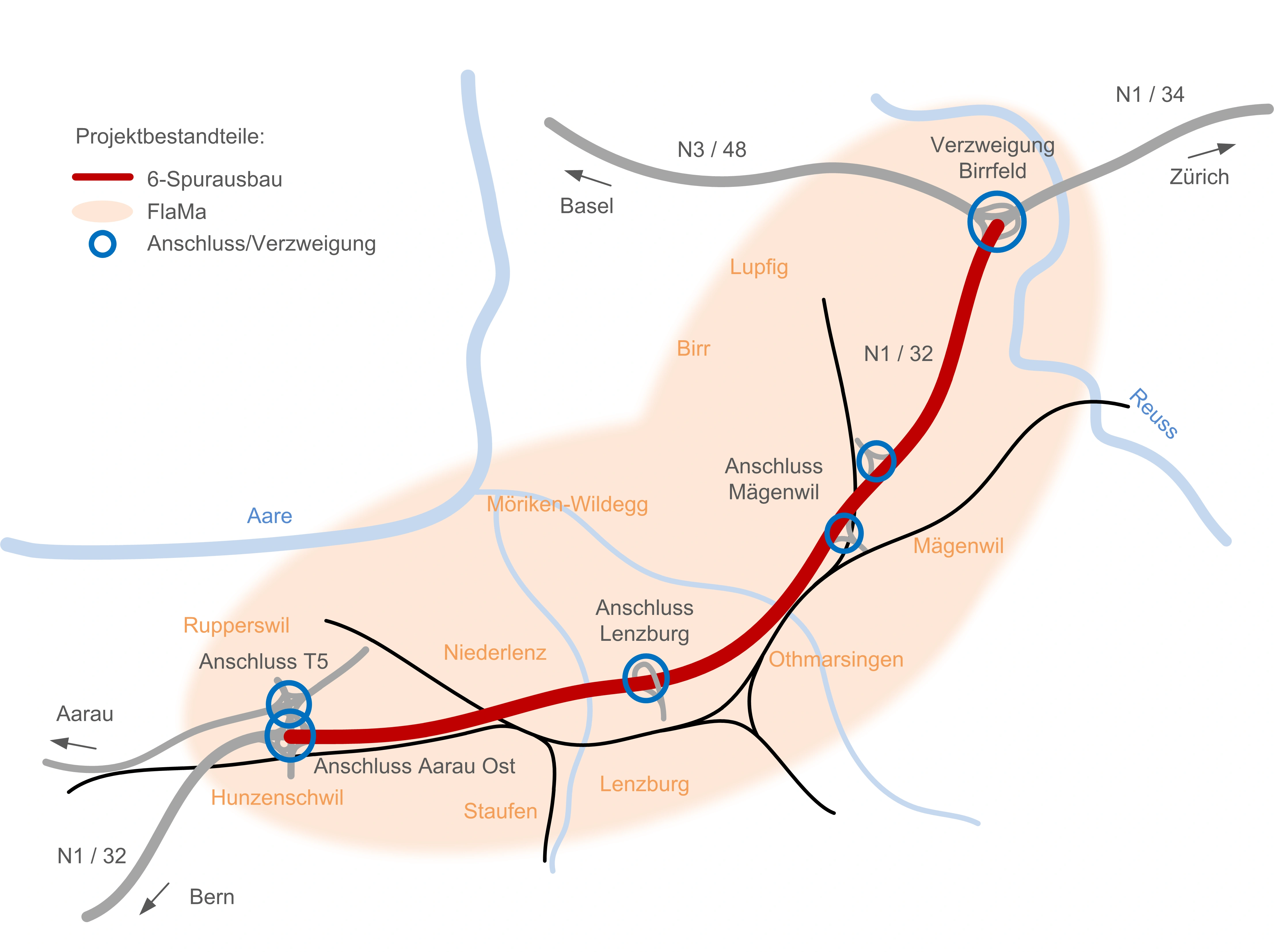

6-Streifenausbau Aarau Ost – Verzweigung Birrfeld – Bauherrenunterstützung

Industries:

Services: