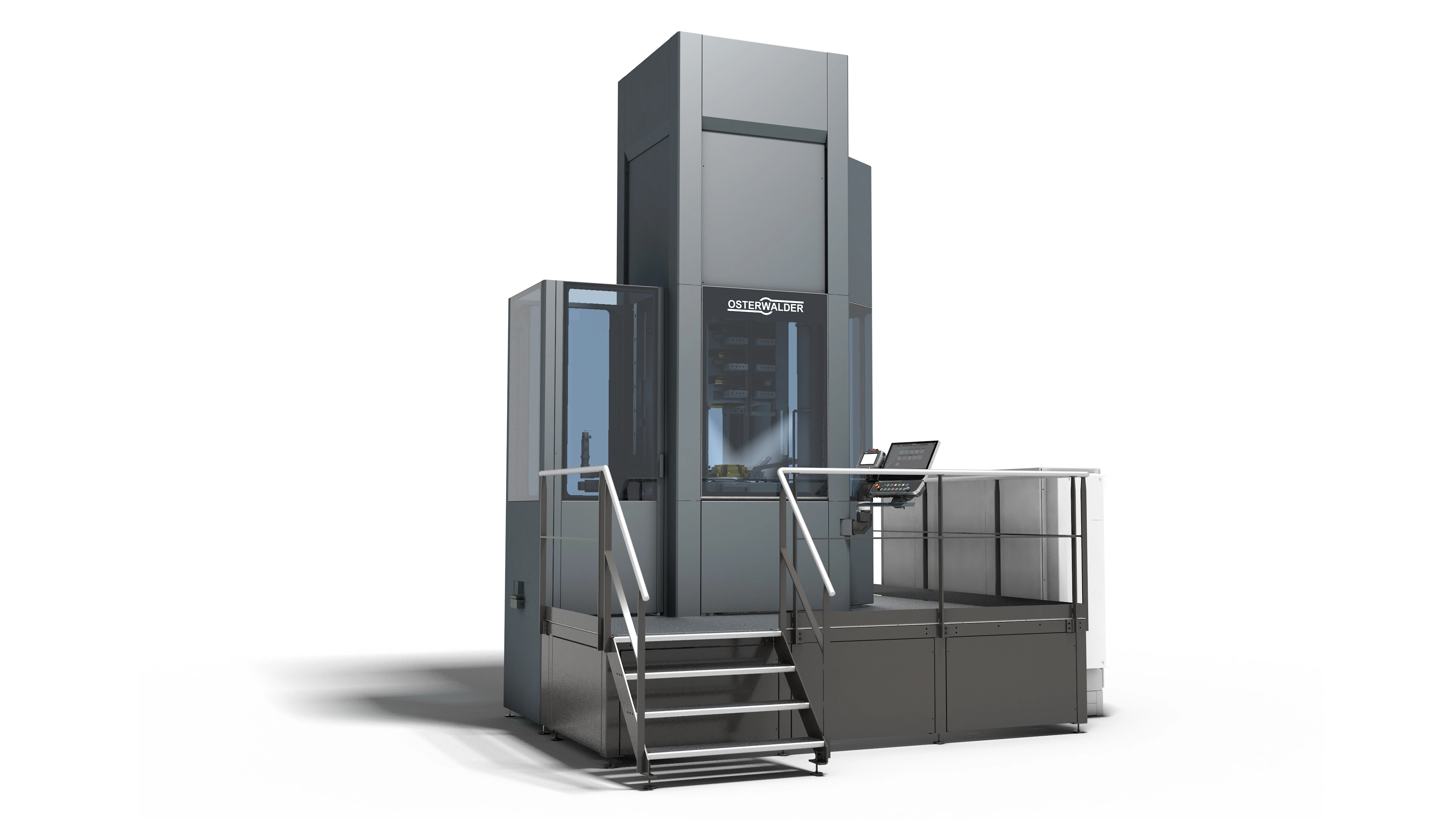

reference project

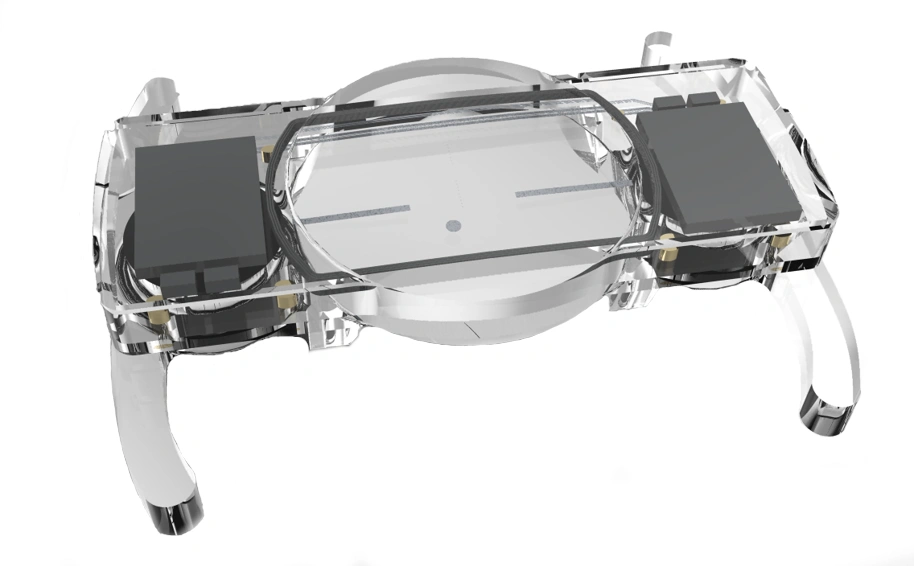

Ivoclar Vivadent – «Bluephase PowerCure» and «Bluephase G4»

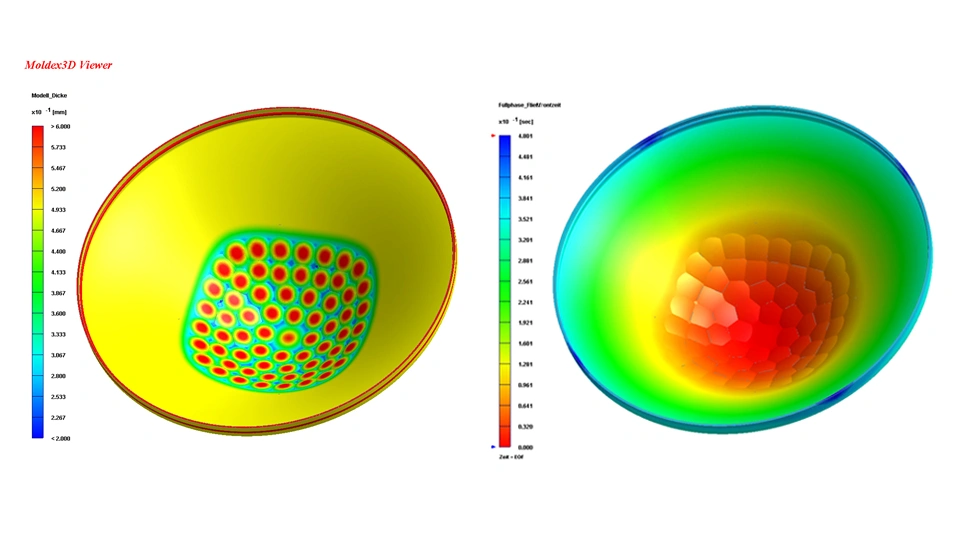

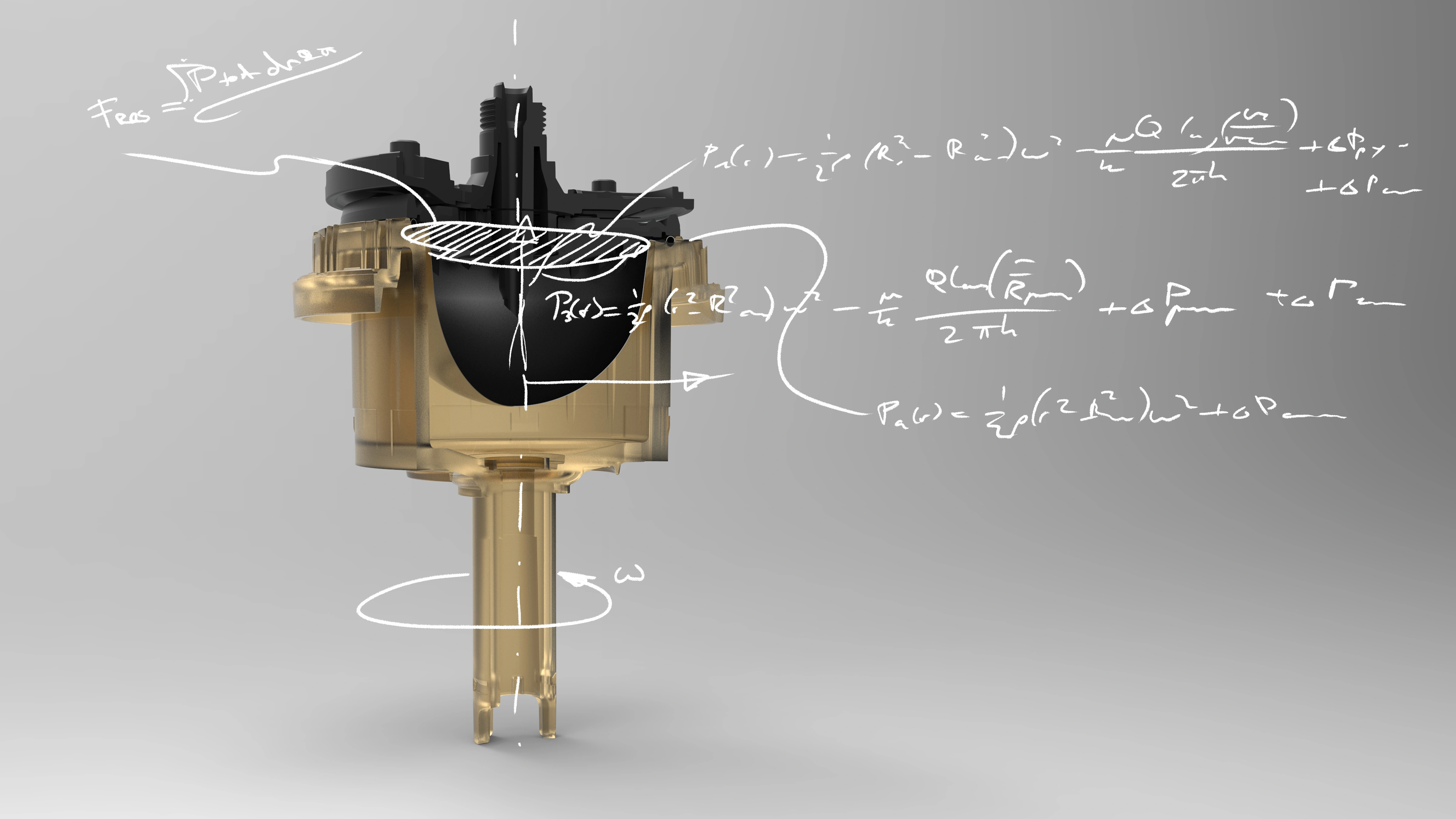

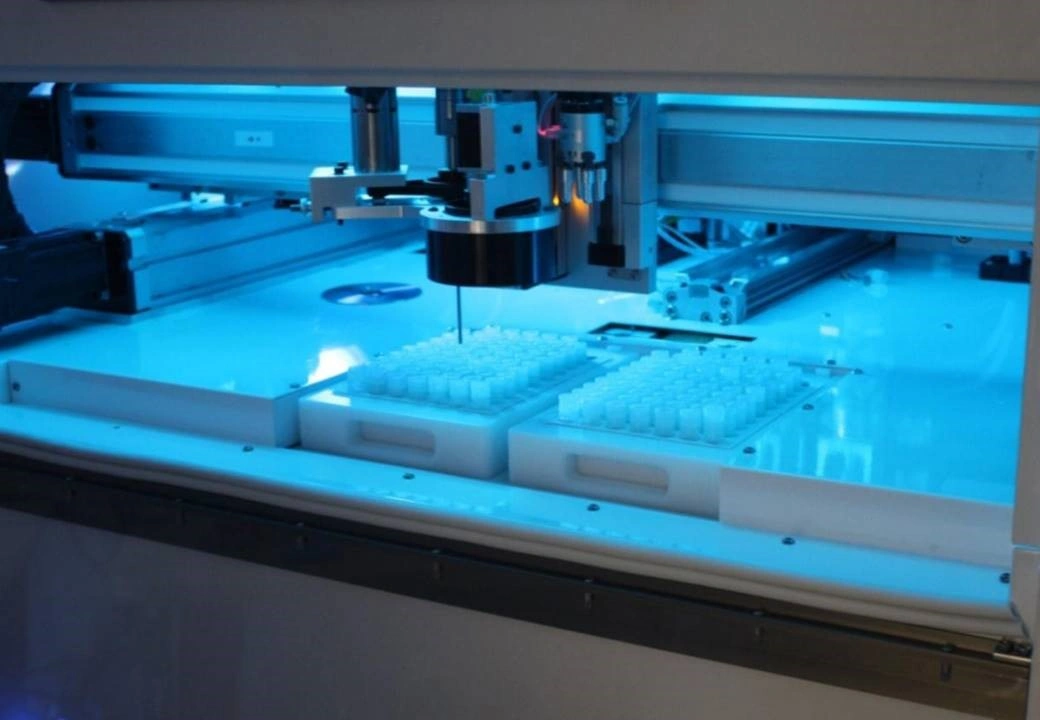

For curing a novel dental filling material, new LED curing lights for dentists are required. Ivoclar Vivadent, a market leader in dental products, appointed Helbling to develop the new smart LED polymerization units "Bluephase PowerCure" and "Bluephase G4".

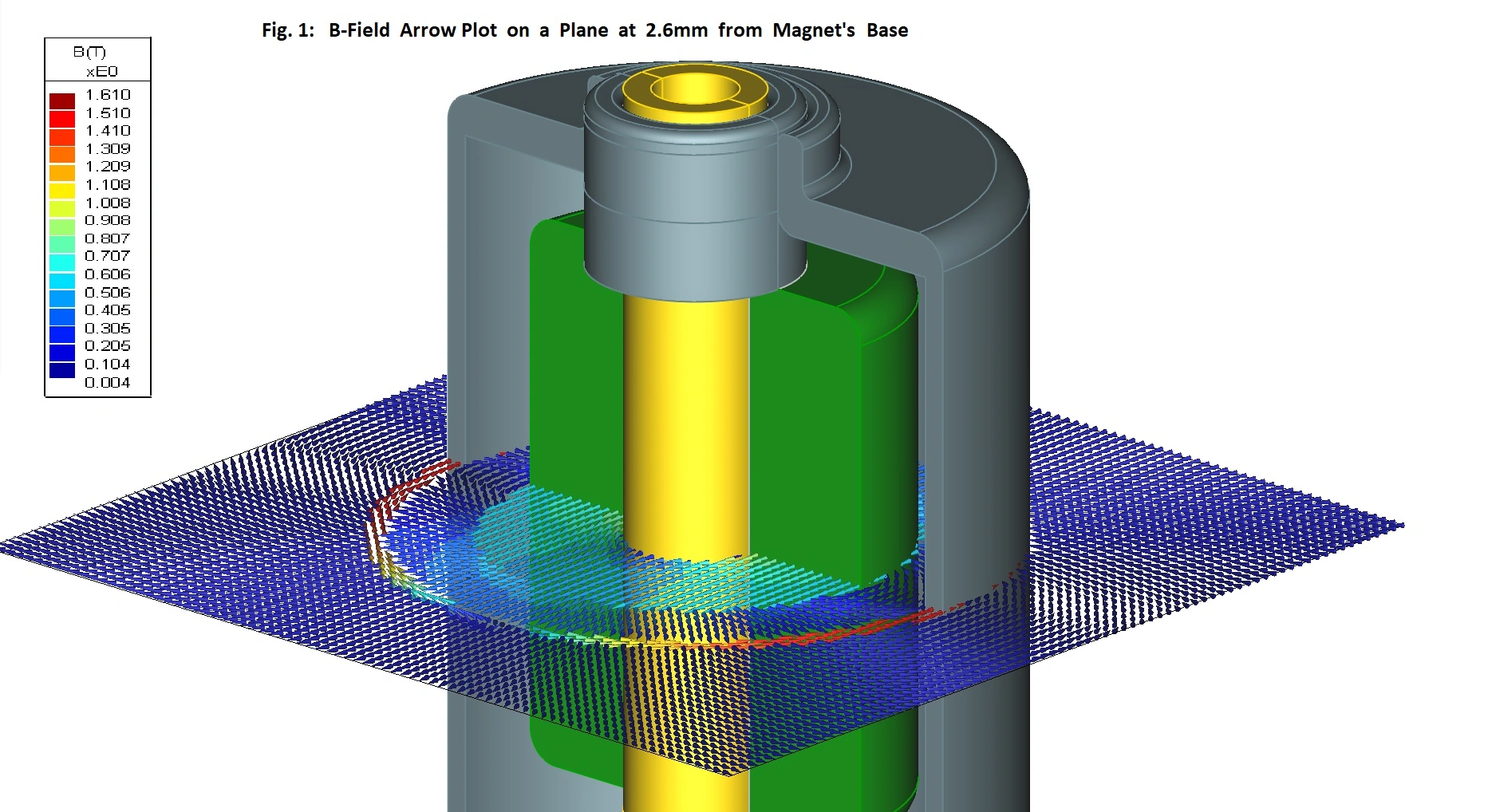

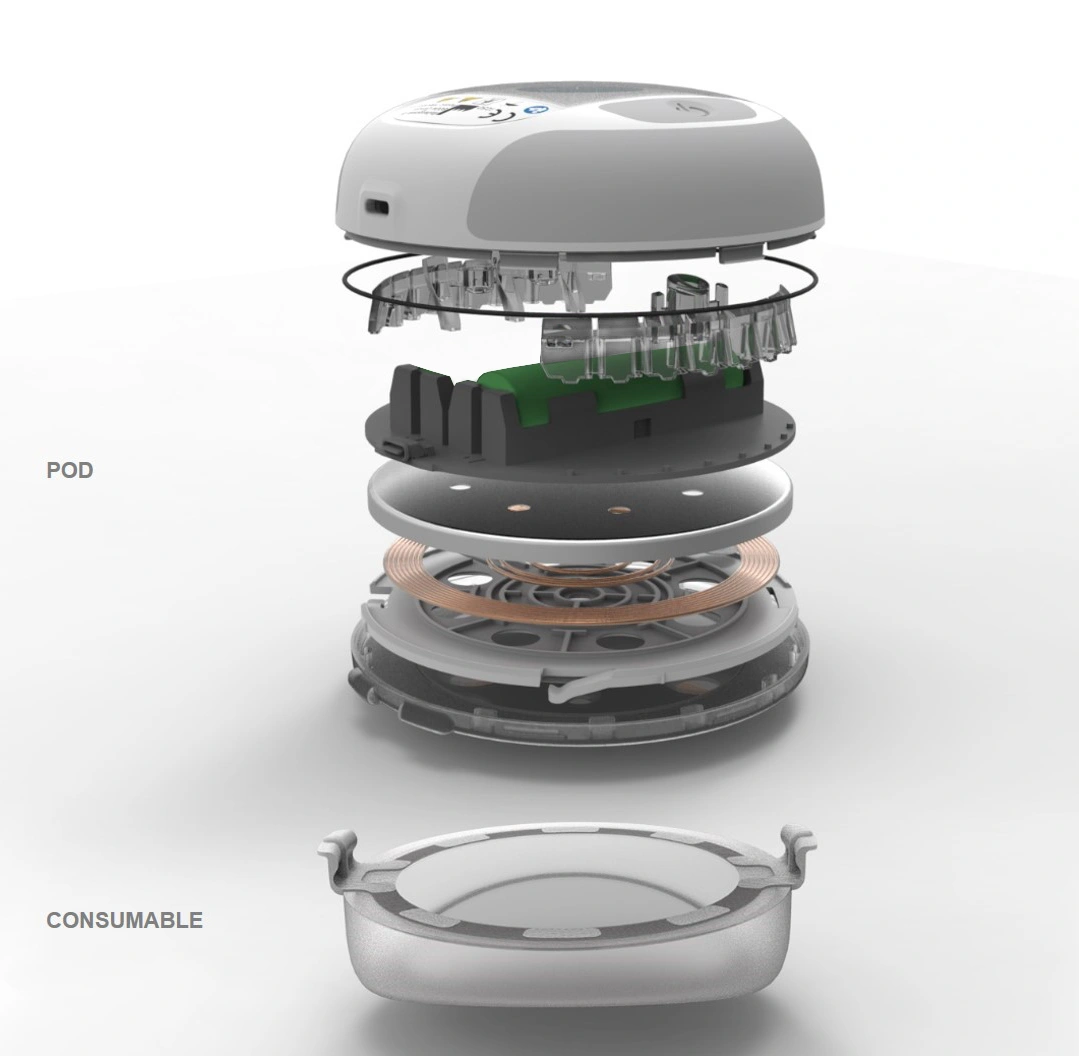

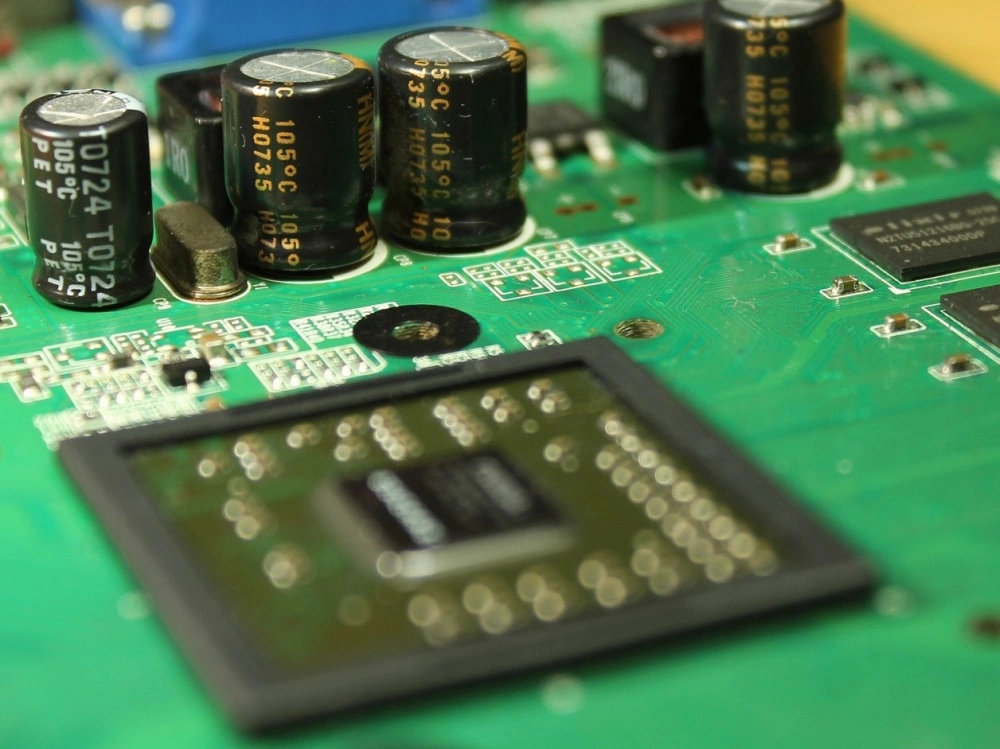

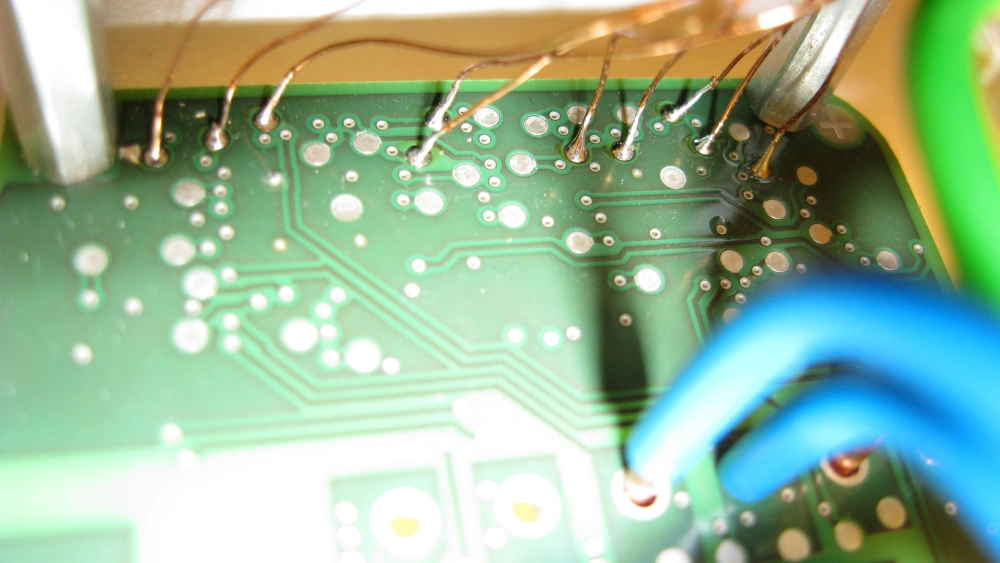

With its built-in reflection sensor, the unit detects incorrect application (movement of the light guide during curing) and alerts the user discretely by vibrating. Exposure time is automatically adjusted. If the unit is incorrectly applied to a significant extent, the procedure is halted. This assistance system combined with a tripling of light output and an effective user interface facilitates a more precise application, shorter exposure times and greater safety. Users can view and analyze development and production-relevant error logs and runtime data using additional software tools developed by Helbling.

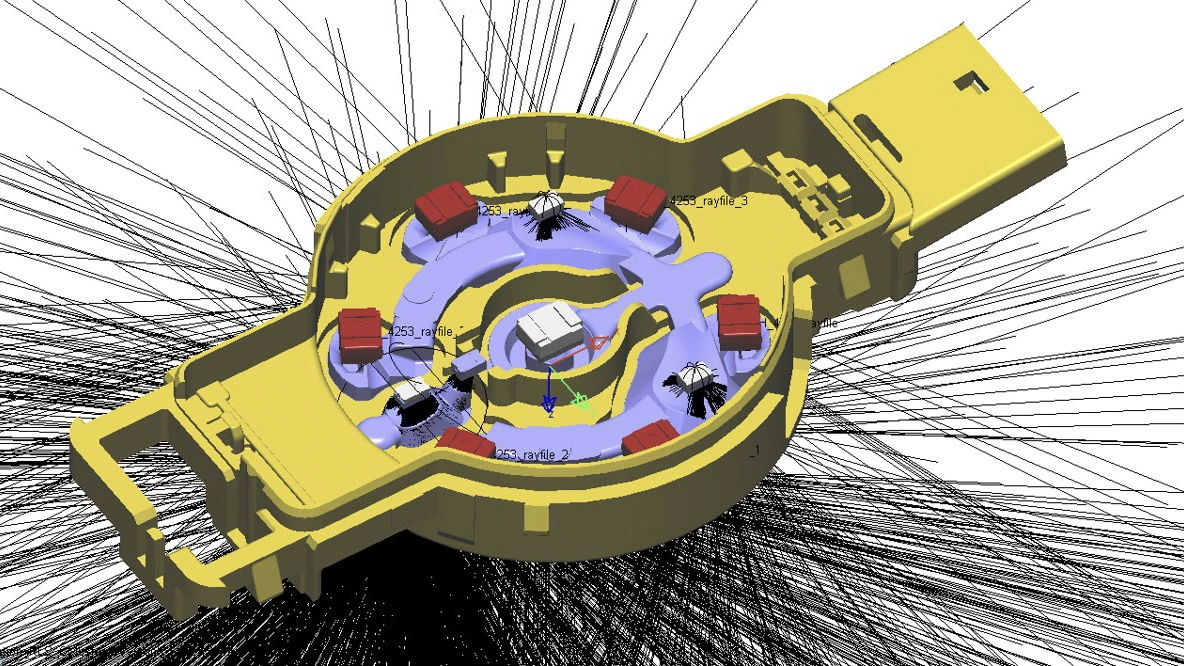

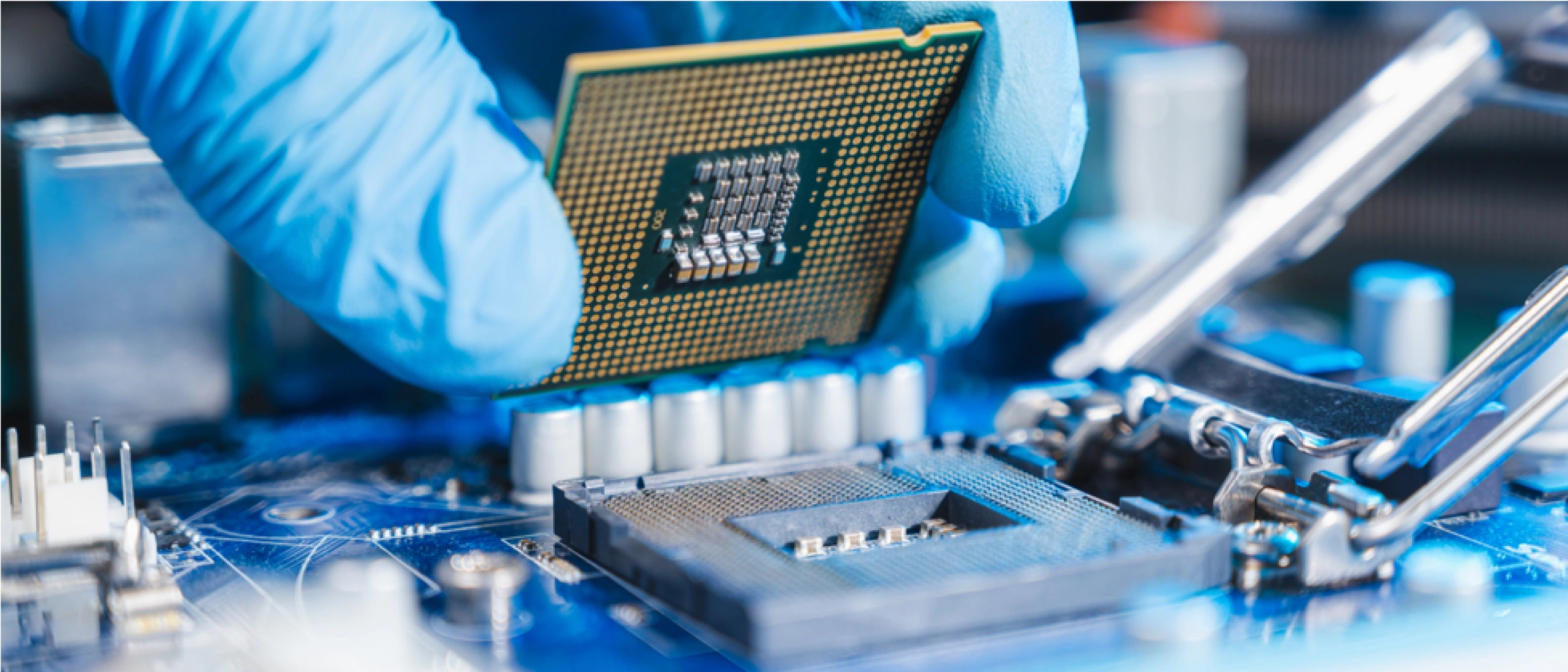

Helbling developed the product in close cooperation with the customer and was responsible for the system. The core team of five people for developing the software, hardware, mechanics, and optics was supported by additional experts in optical efficiency, thermal management, usability, and system integration.

Throughout the entire process, comprehensive certification-compliant documentation to ISO 13485 was created.

With its built-in reflection sensor, the unit detects incorrect application (movement of the light guide during curing) and alerts the user discretely by vibrating. Exposure time is automatically adjusted. If the unit is incorrectly applied to a significant extent, the procedure is halted. This assistance system combined with a tripling of light output and an effective user interface facilitates a more precise application, shorter exposure times and greater safety. Users can view and analyze development and production-relevant error logs and runtime data using additional software tools developed by Helbling.

Helbling developed the product in close cooperation with the customer and was responsible for the system. The core team of five people for developing the software, hardware, mechanics, and optics was supported by additional experts in optical efficiency, thermal management, usability, and system integration.

Throughout the entire process, comprehensive certification-compliant documentation to ISO 13485 was created.

Services

Industries

Key Figures

- Polyvision for detecting incorrect application

- Increased light output for curing within 3 seconds

- Integrated acceleration sensor

- Same installation space with more functionality

- User interface with transmitted light display

- Wireless charging

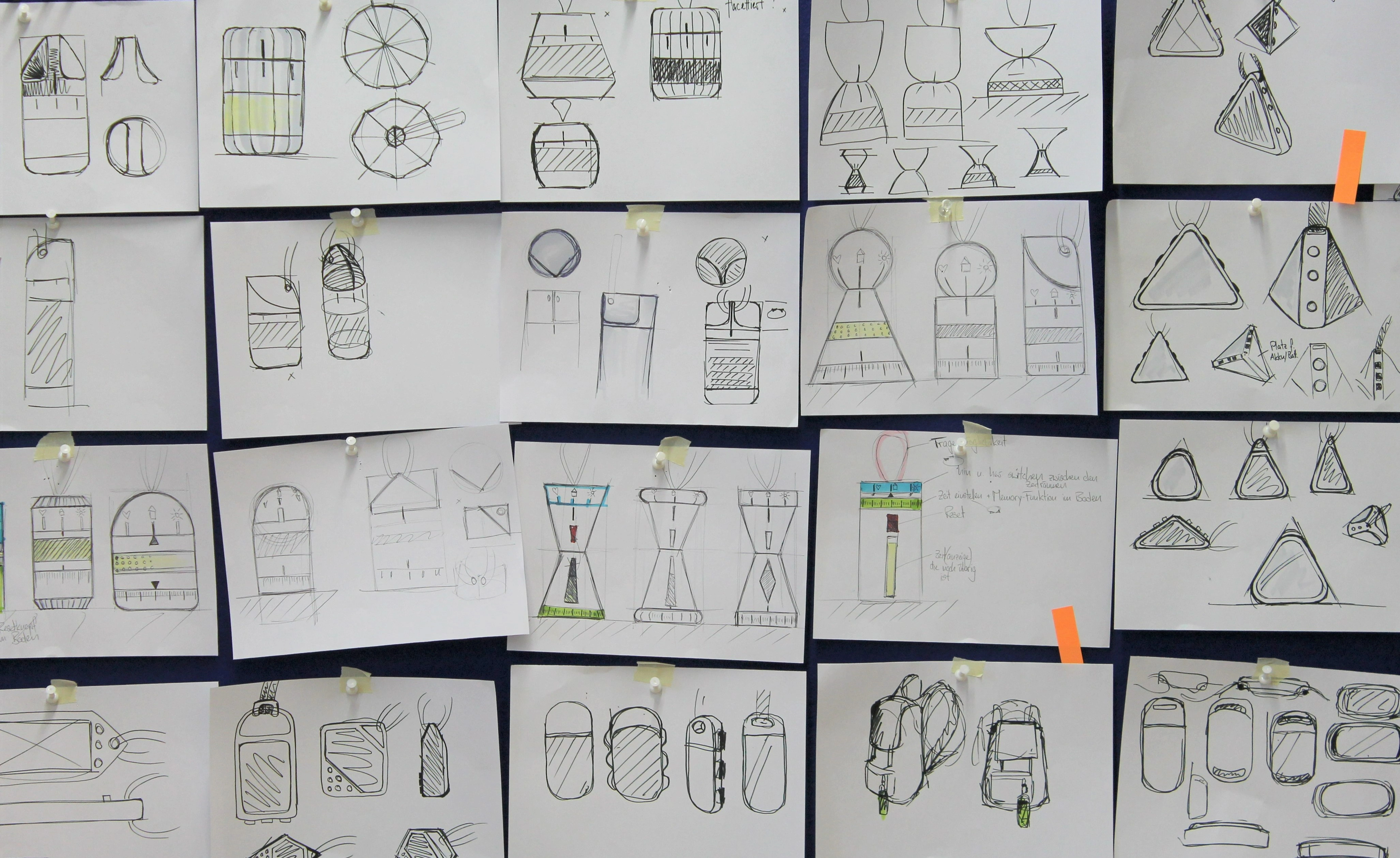

Our Contribution

- Develop software, hardware, mechanics, and optics

- Patent optical design

- Develop innovative user interface

- Integrate industrial design

- Software tools for logging error logs and runtime data

- Certification-compliant documentation to ISO 13485

Outcome

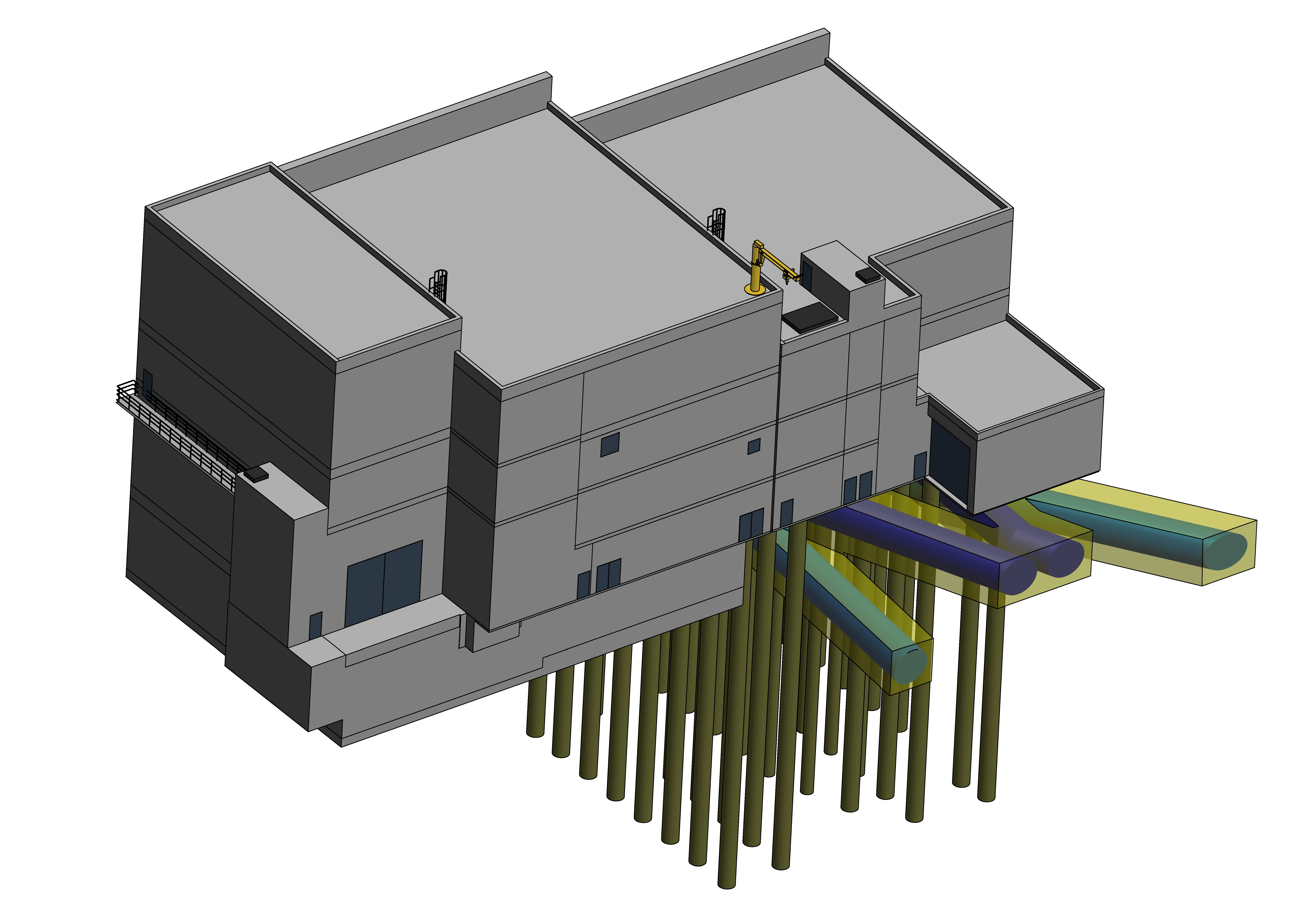

Production costs were kept within budget despite higher complexity, tripling of unit performance, and relocation of production from Asia to Europe. Several product awards confirm the success of the market launch.

Contact

Cases

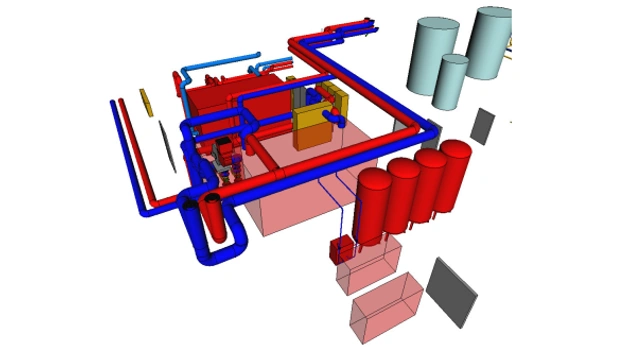

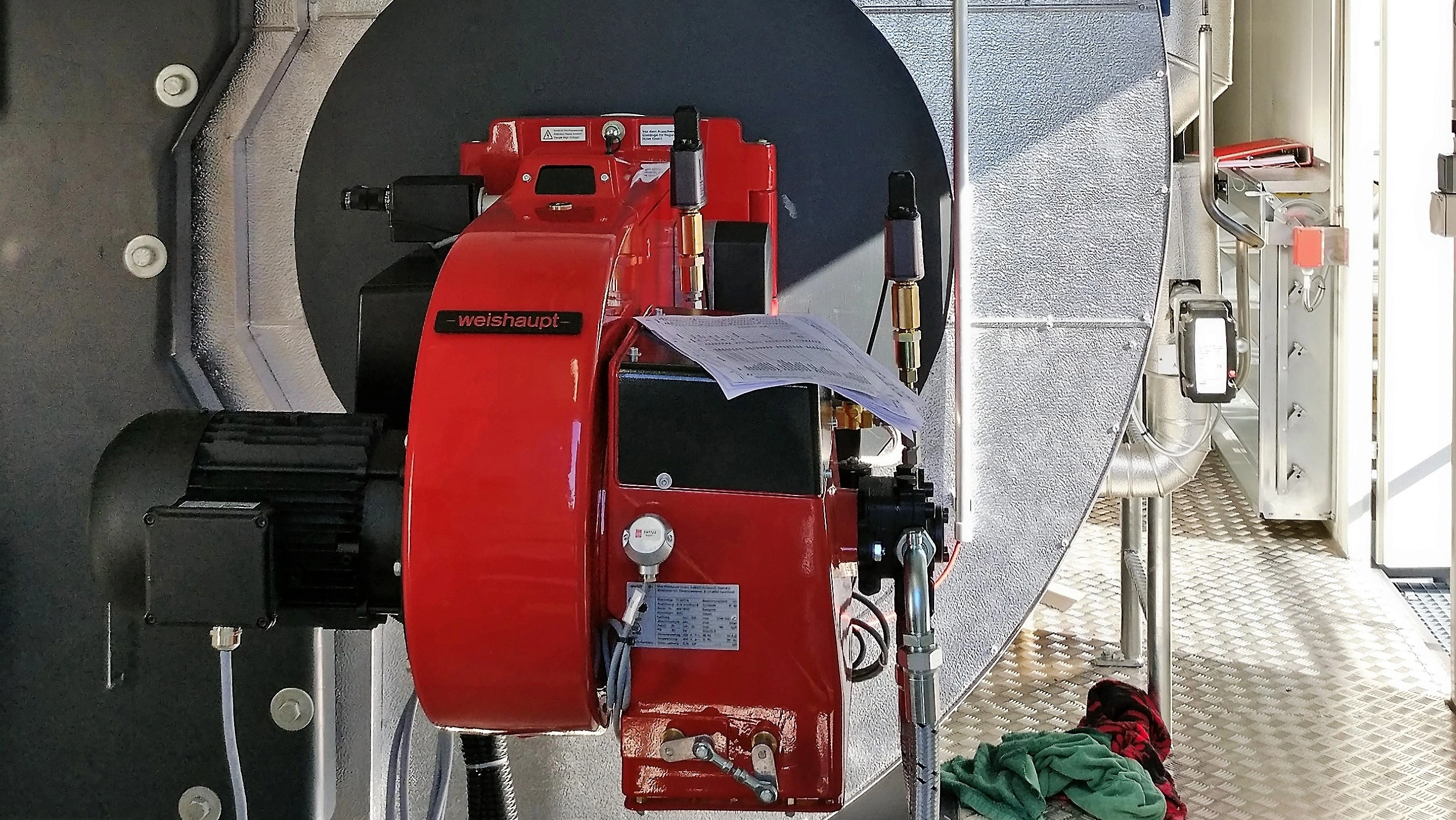

Internationales Unternehmen der Papierindustrie – Analyse des Dampfsystems

Industries:

Services:

Cases

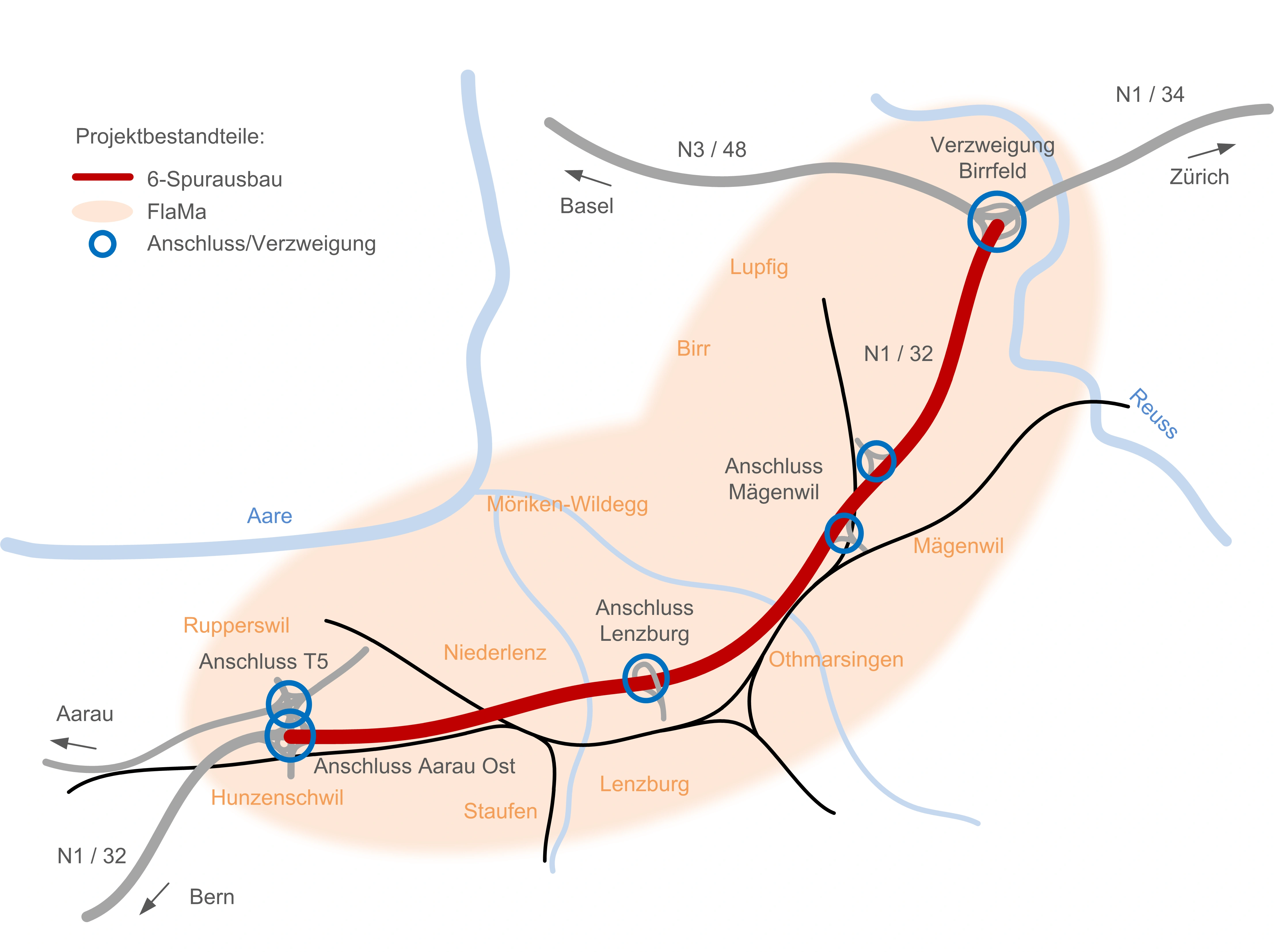

6-Streifenausbau Aarau Ost – Verzweigung Birrfeld – Bauherrenunterstützung

Industries:

Services: