Project

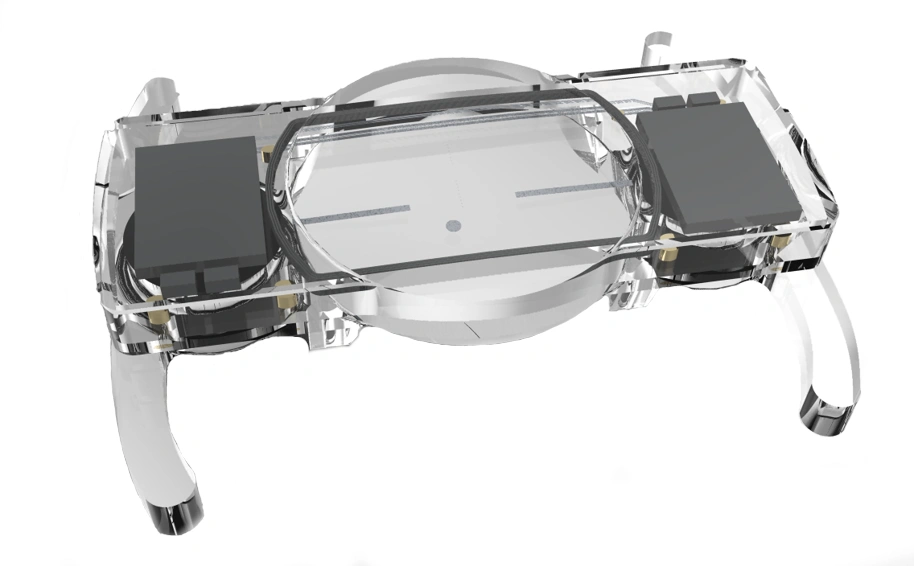

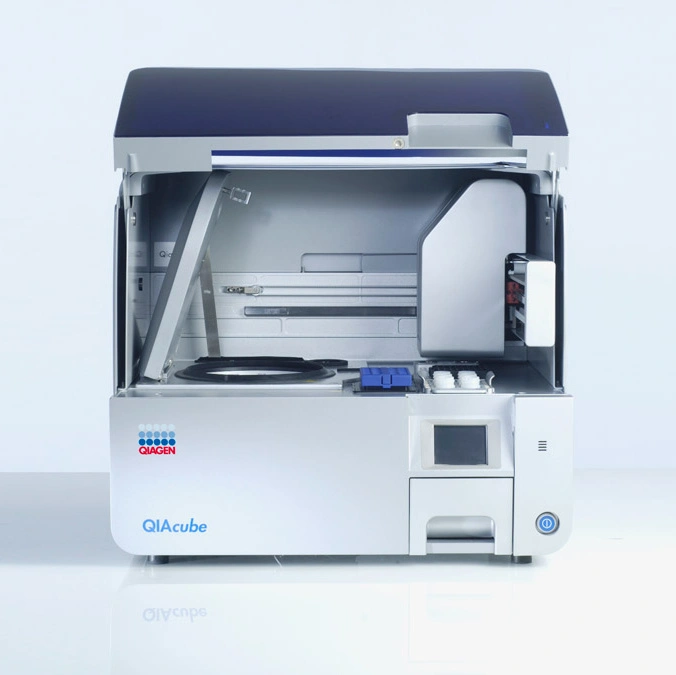

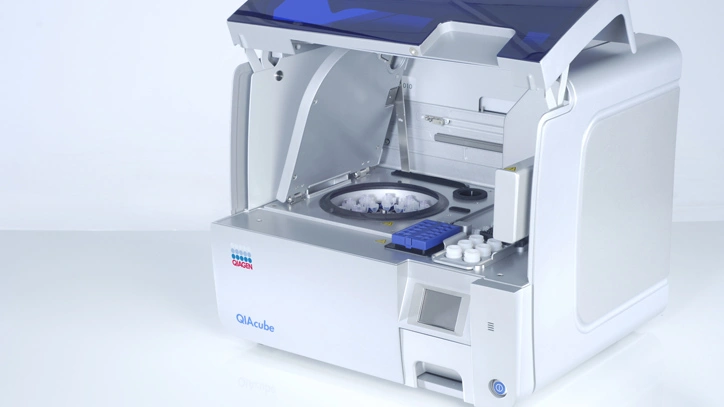

QIAcube

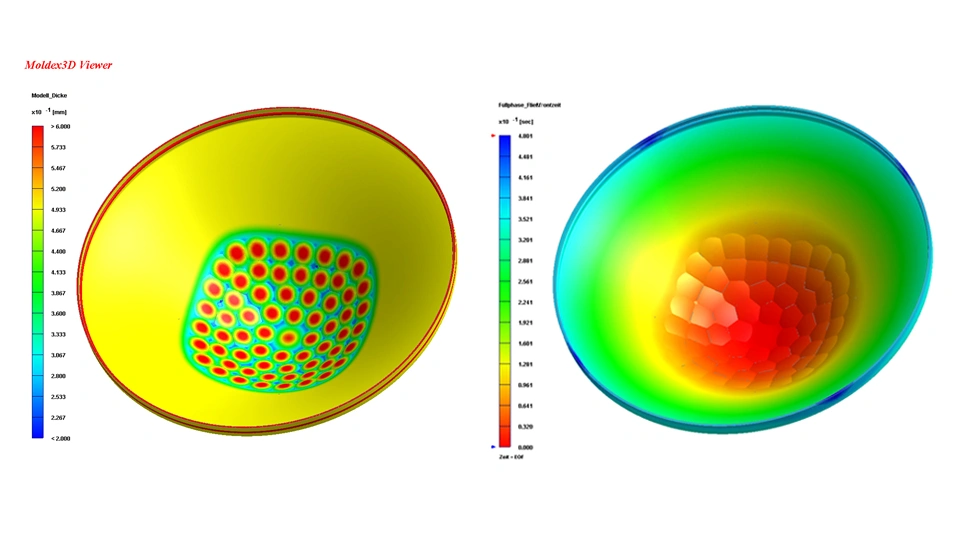

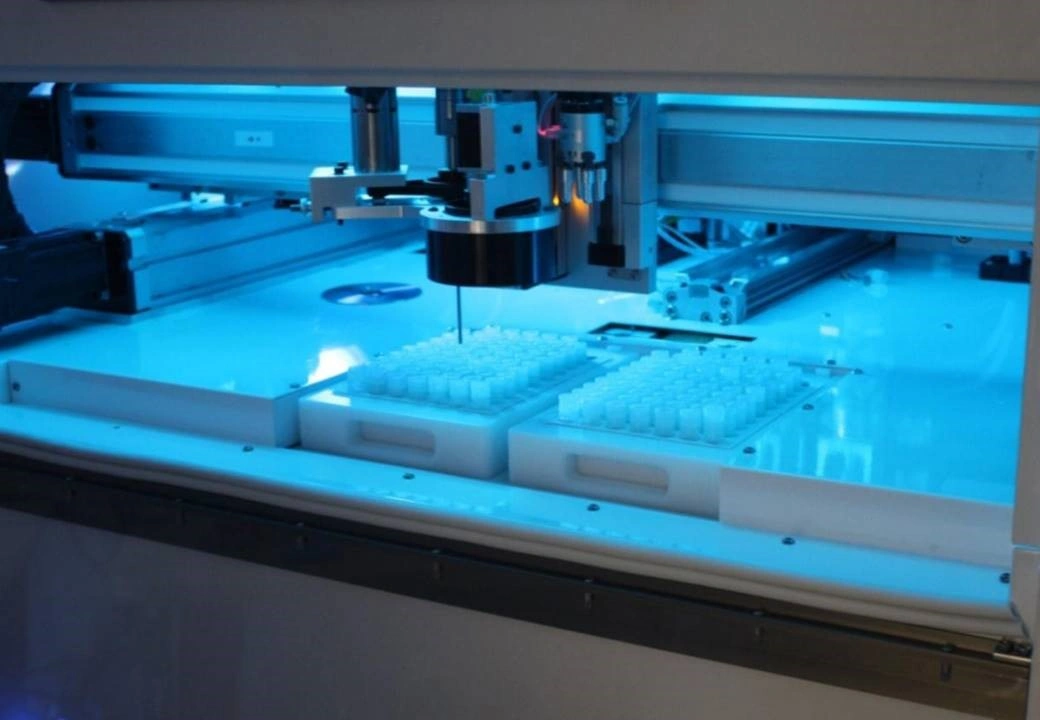

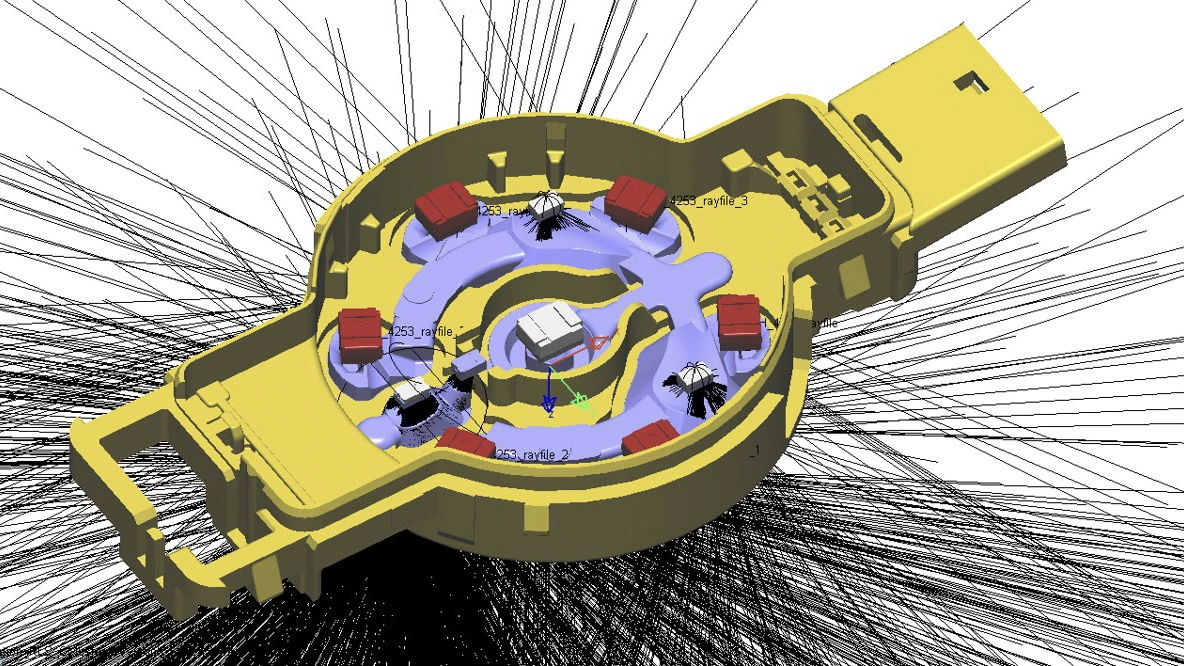

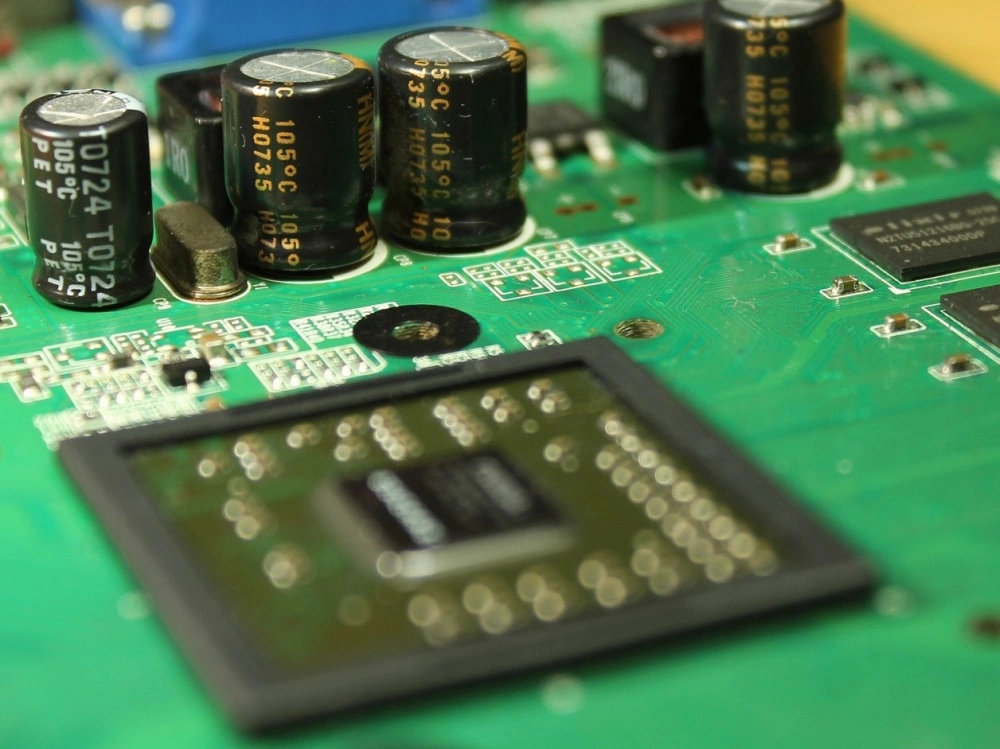

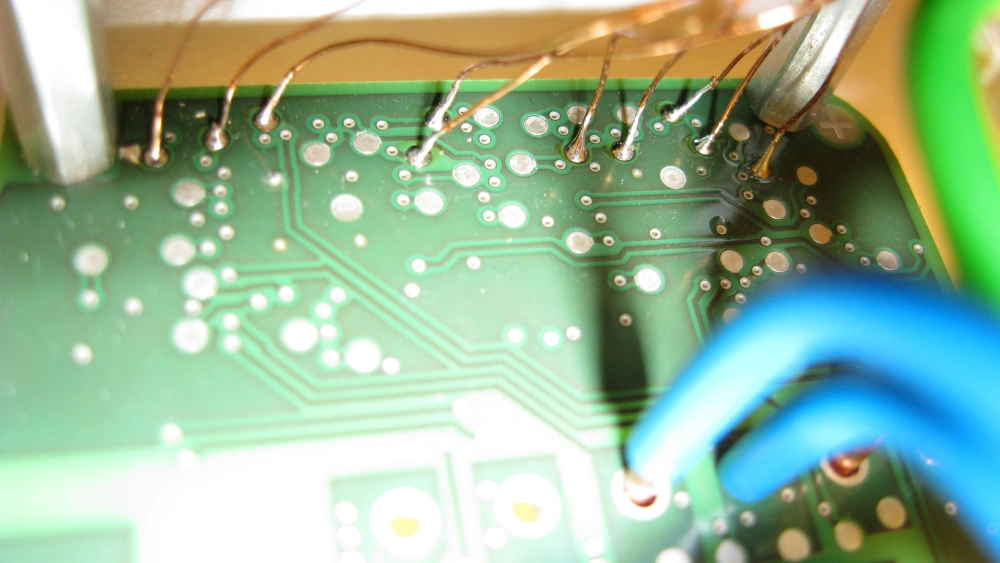

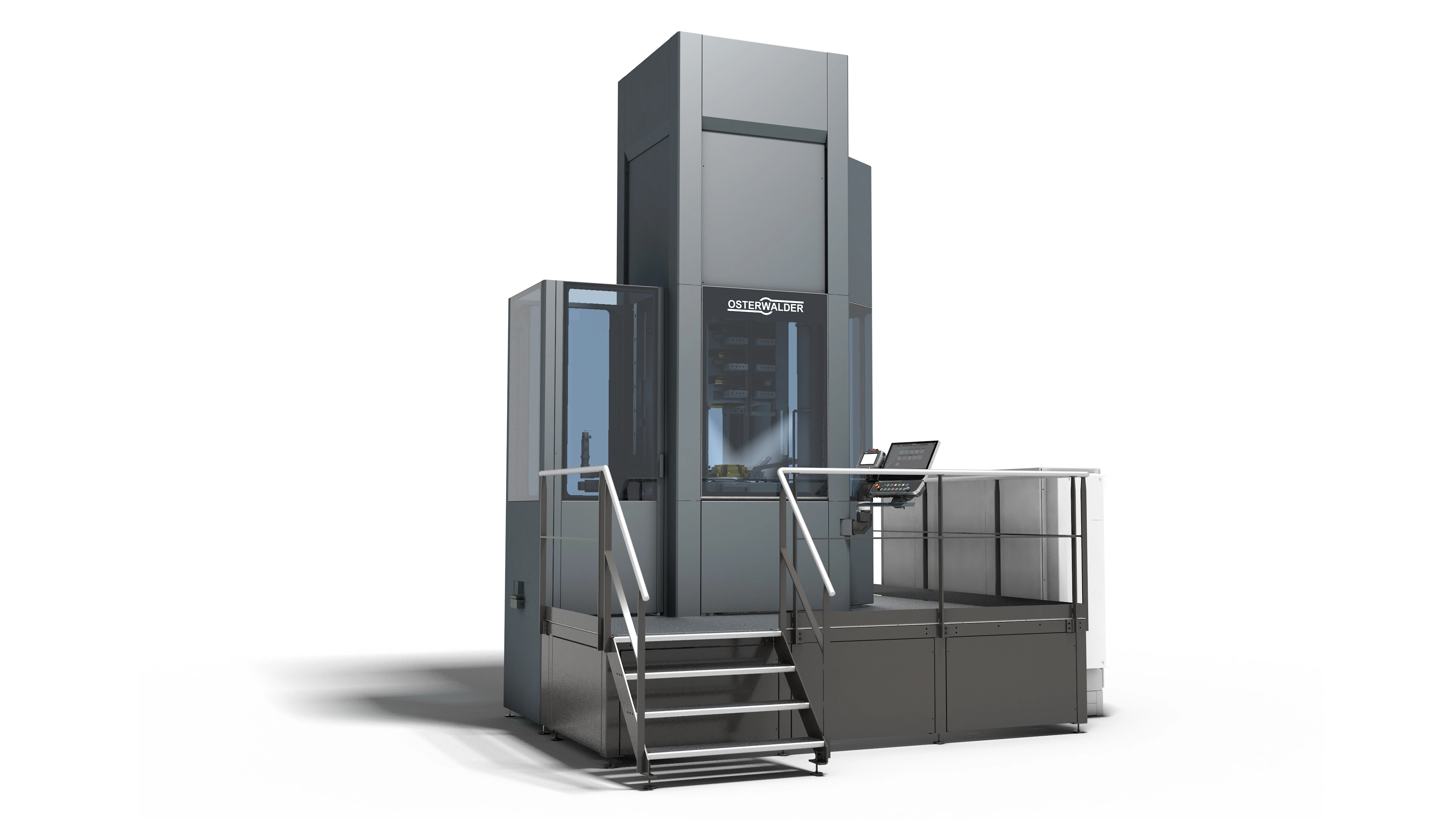

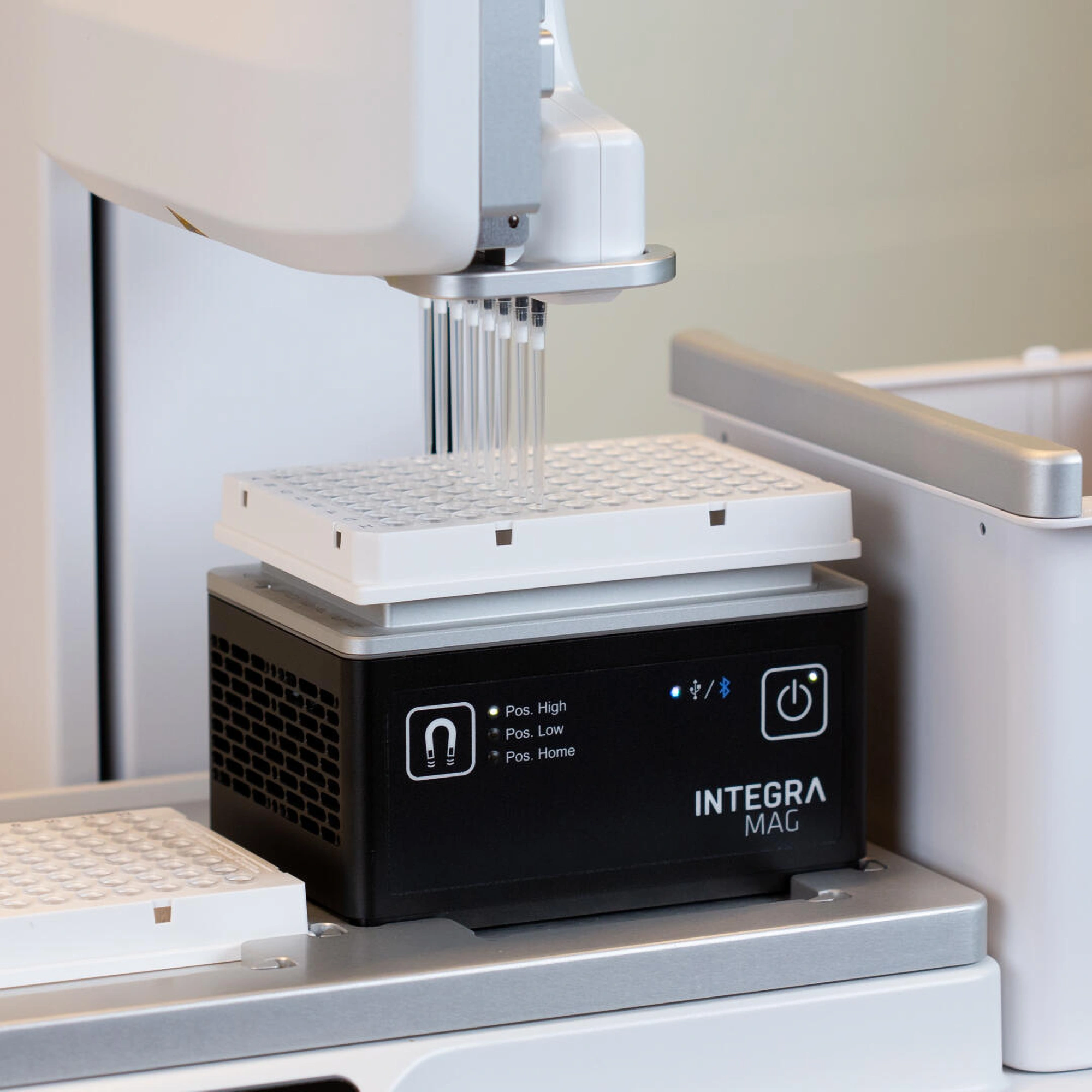

Scientists used to require several pieces of equipment and a multi-step process to purify biomolecules like nucleic acids or proteins. Nowadays, the QIAcube does it all automatically – in one square meter of space. Helbling developed this device for and in collaboration with QIAGEN, from the initial idea through to series production.

QIAGEN wanted to bring a device to market as swiftly as possible that could automatically purify protein or nucleic acid samples in QIAGEN's proven spin columns rather than using the current manual process. Automated systems such as this would not only boost laboratories' productivity but also improve the reproducibility and reliability of test results. Additionally, the automated system needed to be compact and easy enough to operate that even smaller labs could make efficient use of it. Since the internal R&D department was working to capacity on the development of another device platform, QIAGEN was looking for an external development partner with the necessary know-how: from mechanics, electronics and software all the way to liquid handling. On the basis of these criteria, QIAGEN chose Helbling and thus to continue the successful collaboration which had already begun many years before.

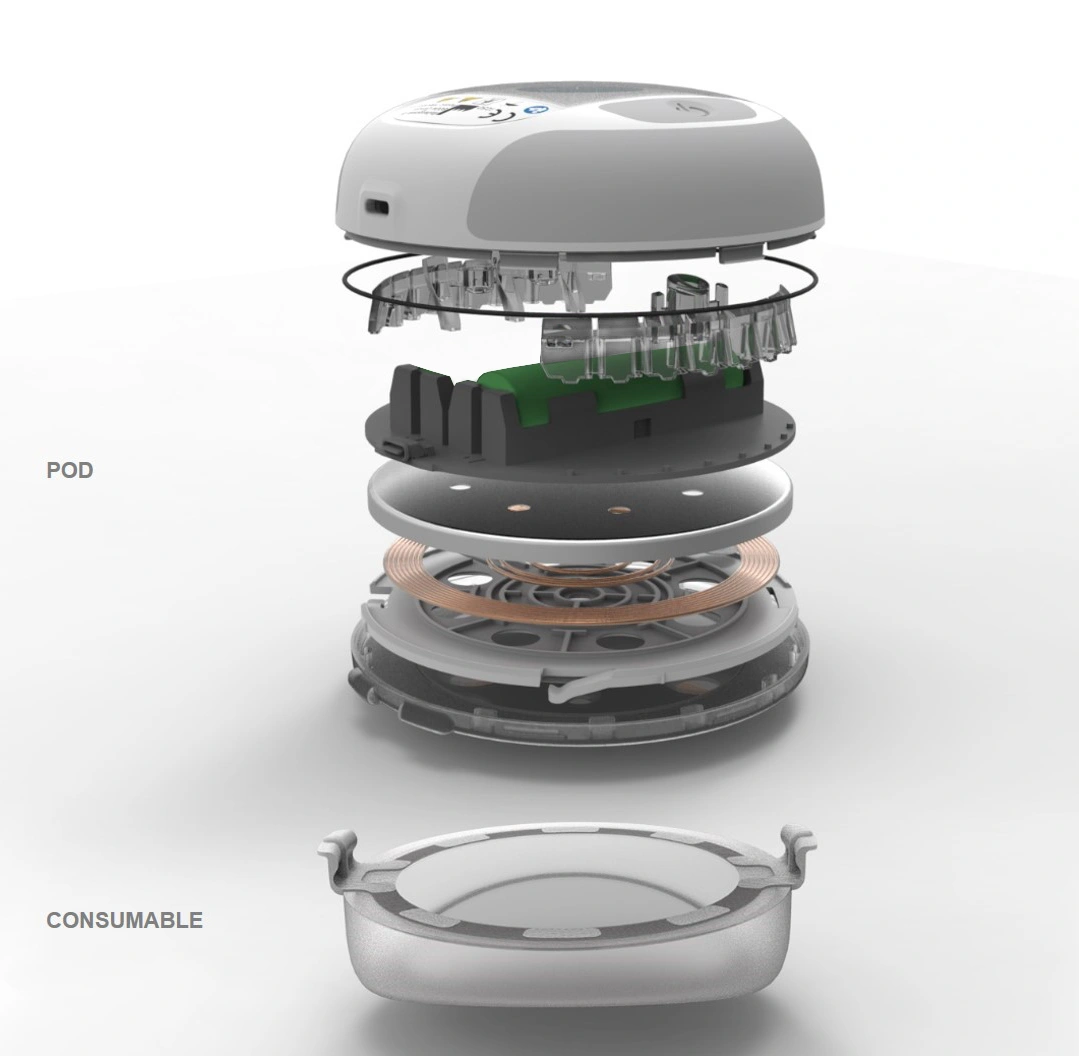

Key modules:

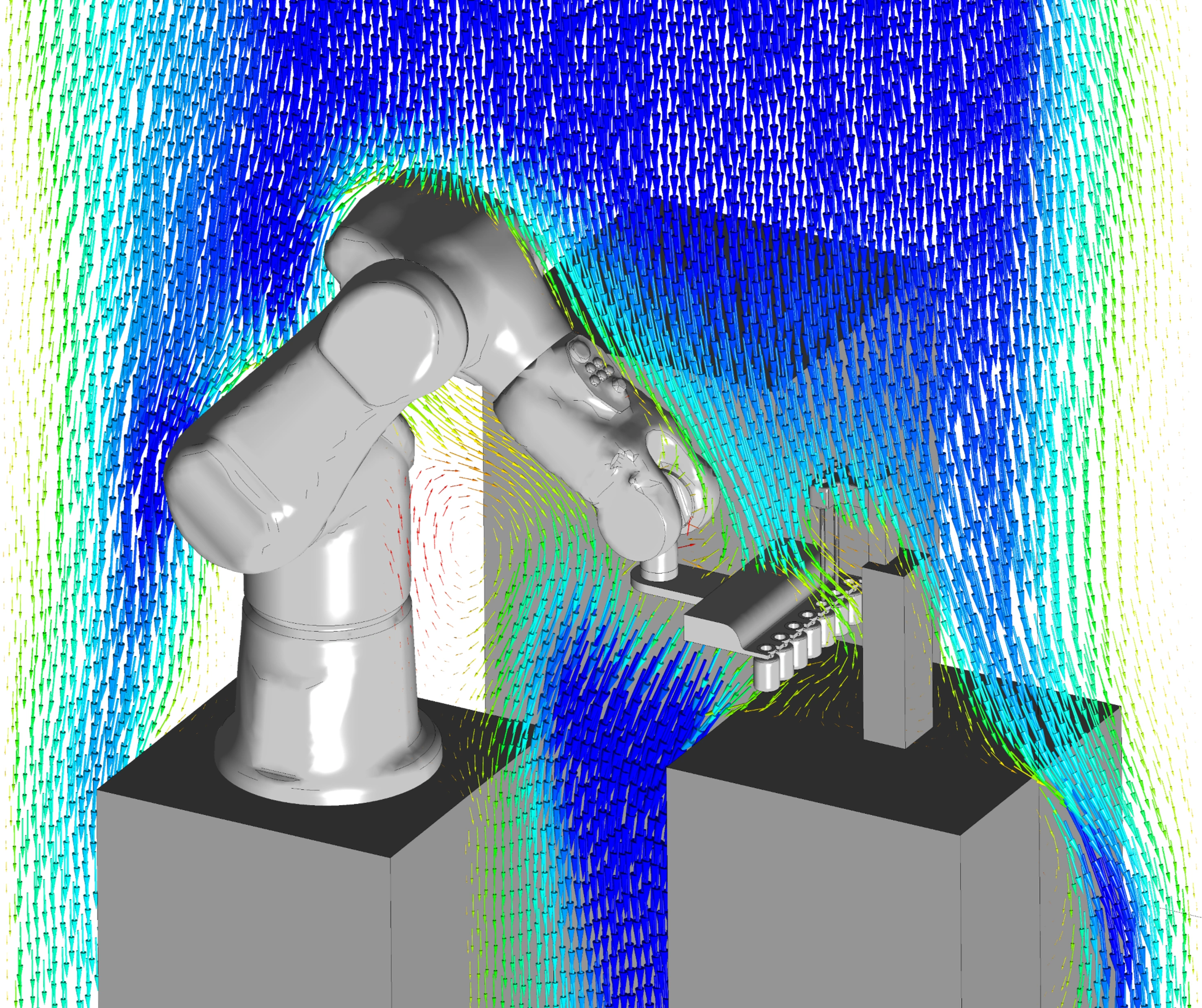

Liquid handling module (syringe)

Gripper module

XYZ handling unit

Centrifuge

Heated shaker

Sensors for in-process controls

HMI with touch screen

QIAGEN wanted to bring a device to market as swiftly as possible that could automatically purify protein or nucleic acid samples in QIAGEN's proven spin columns rather than using the current manual process. Automated systems such as this would not only boost laboratories' productivity but also improve the reproducibility and reliability of test results. Additionally, the automated system needed to be compact and easy enough to operate that even smaller labs could make efficient use of it. Since the internal R&D department was working to capacity on the development of another device platform, QIAGEN was looking for an external development partner with the necessary know-how: from mechanics, electronics and software all the way to liquid handling. On the basis of these criteria, QIAGEN chose Helbling and thus to continue the successful collaboration which had already begun many years before.

Key modules:

Liquid handling module (syringe)

Gripper module

XYZ handling unit

Centrifuge

Heated shaker

Sensors for in-process controls

HMI with touch screen

Services

Key Figures

- Automation of the existing QIAGEN spin columns

- Automation solution for 1 to 12 samples

- Throughput of 96 different samples per day

- Fully automatic solution

- Same or better results and processing time compared to manual processing of spin columns

Our Contribution

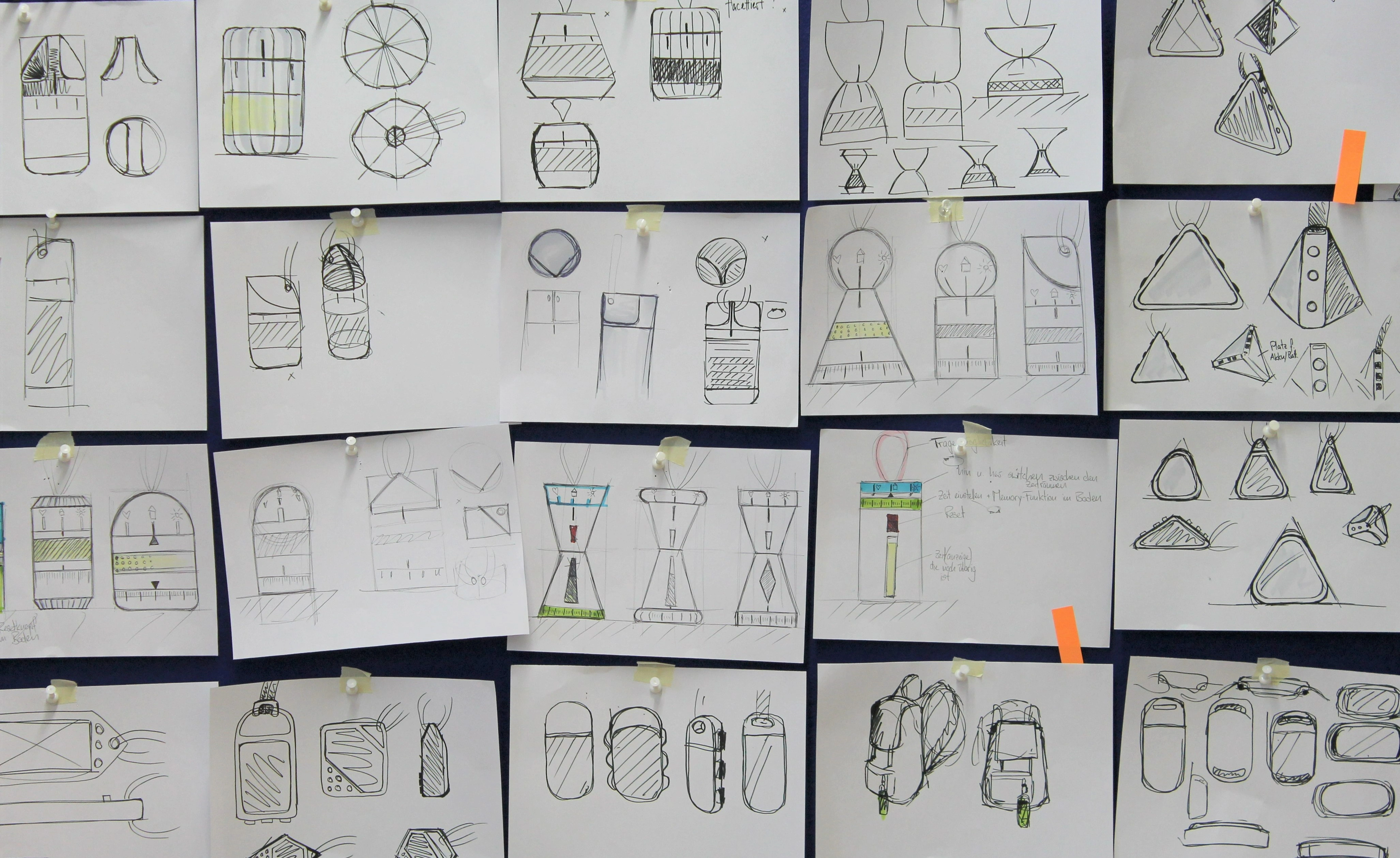

- Development in close cooperation with QIAGEN application department and customer’s standardized approach (SOP) to ISO 13485

- Performing system verification

- Drafting touch sample for various modules

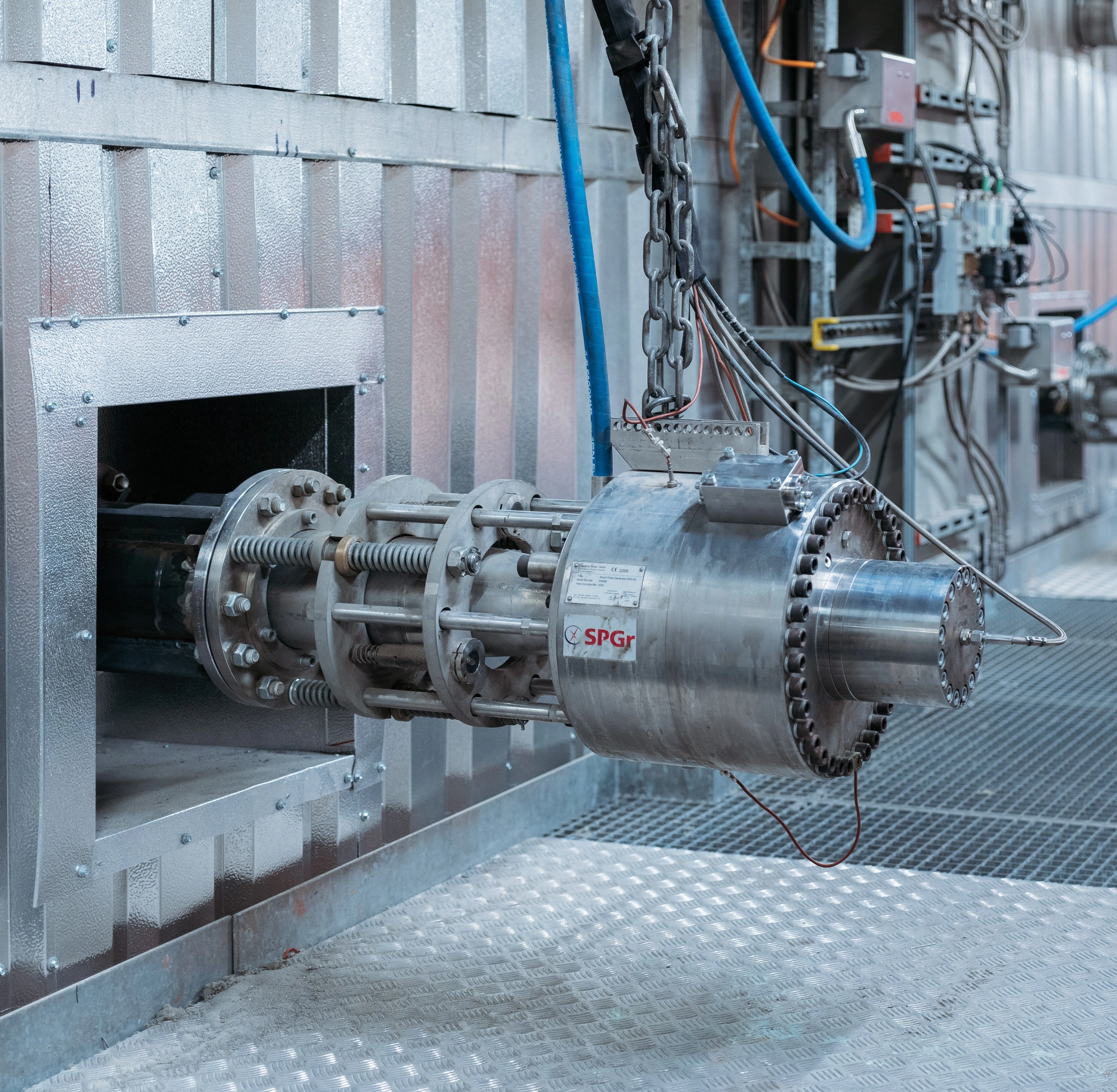

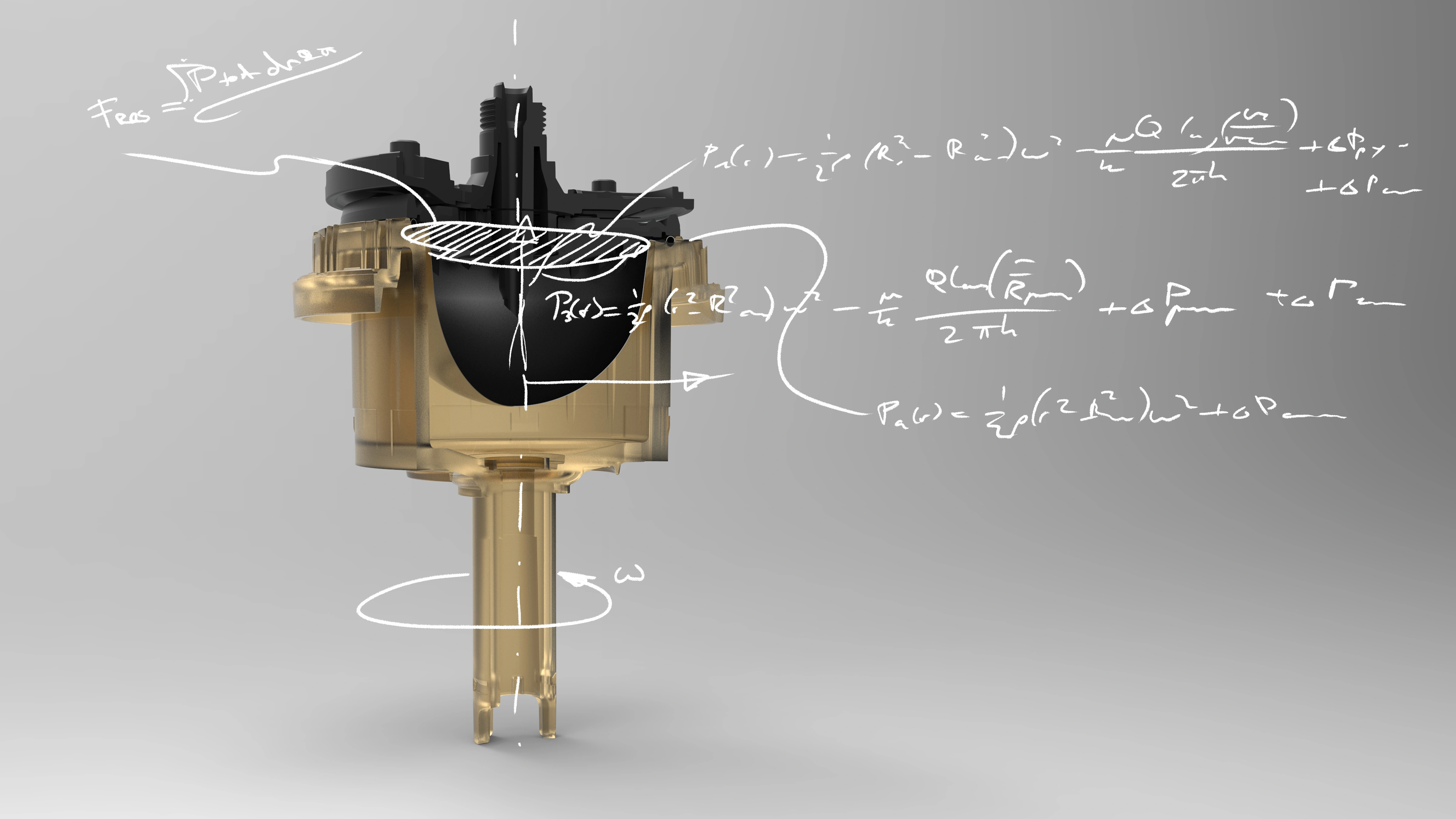

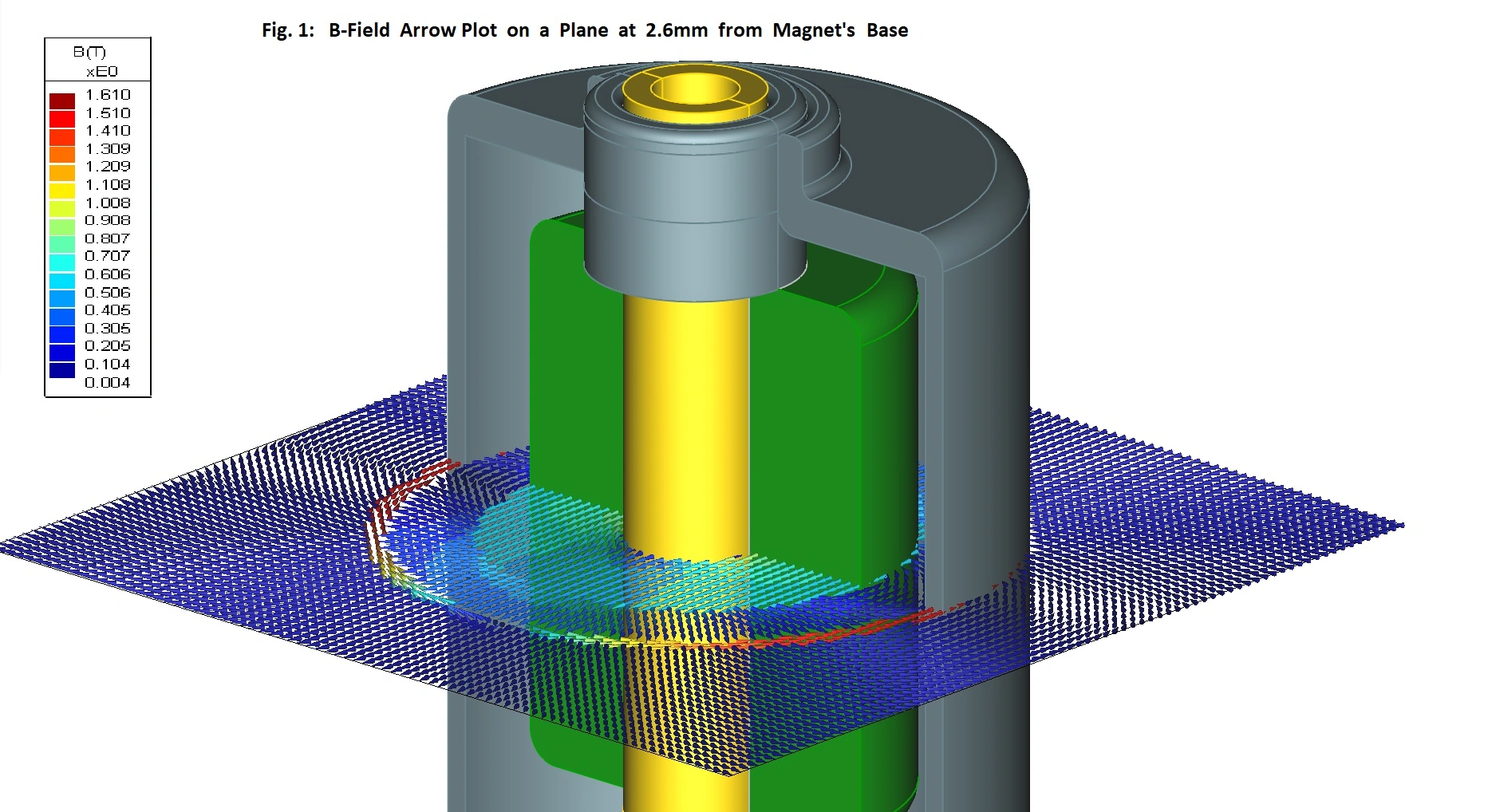

- Implementing innovative centrifuge technology instead of alternative positive pressure technology

- Integrating all device functions in a model in concept phase

- Comprehensive laboratory tests

- Supplying design data for rapid prototyping

- Prototype testing

- Assisting with technical questions in production of pilot series

Outcome

In 2007, at the QIAcube’s very first public presentation at “LabAutomation”, the world’s largest trade show for laboratory technologies in Palm Springs (USA), QIAGEN’s QIAcube was presented with the industry’s most important innovation prize: the New Product Award (NPA) from the Association for Laboratory Automation (ALA).

Also in 2007, QIAGEN received the Red Dot Award in the “Product Design” category for its QIAcube. The jury praised the QIAcube’s innovative strength, functionality, processing quality and ergonomics.

Overall, the QIAcube led to the attainment of numerous new patents for QIAGEN.

Contact

Cases

Internationales Unternehmen der Papierindustrie – Analyse des Dampfsystems

Industries:

Services:

Cases

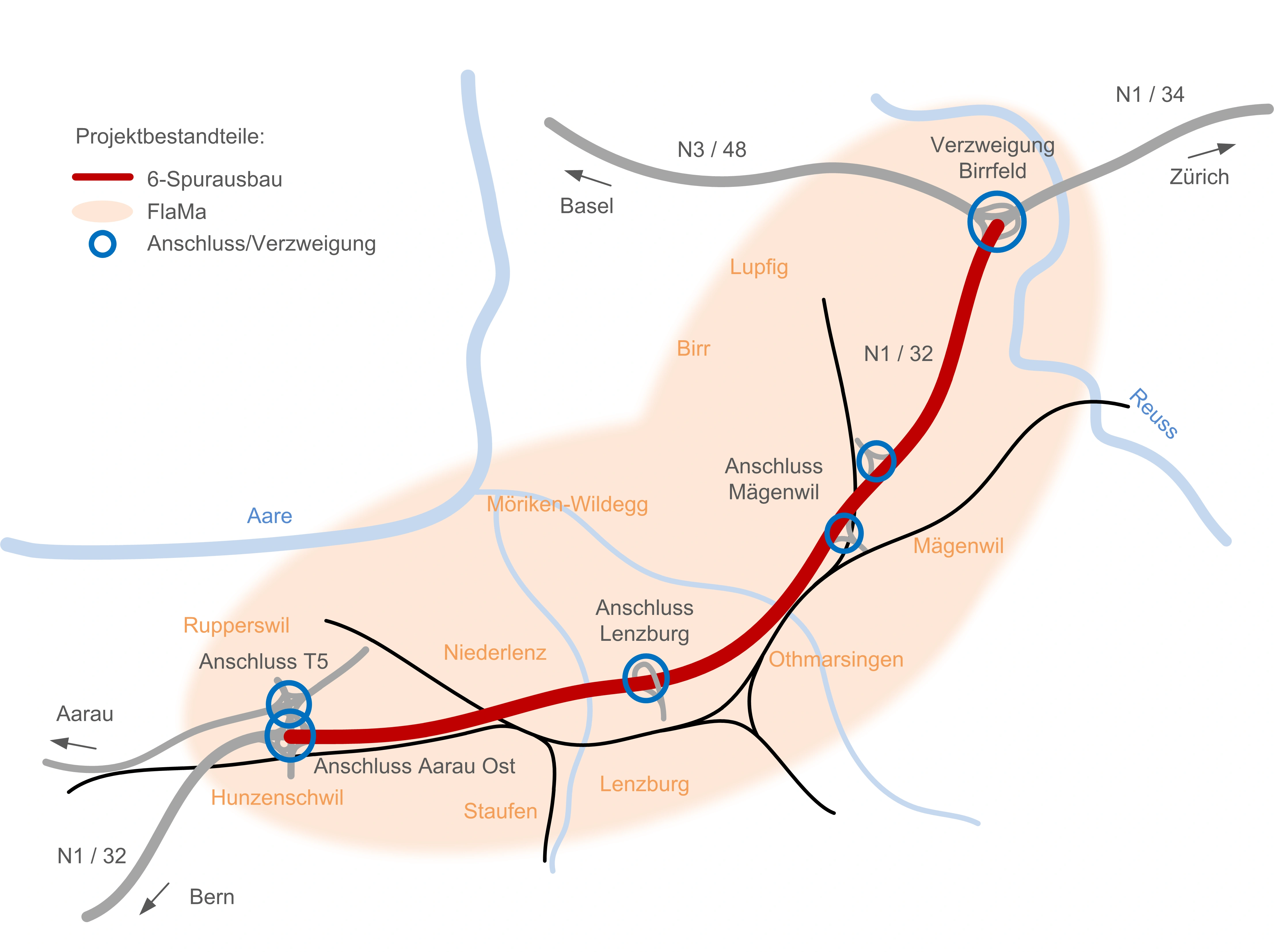

6-Streifenausbau Aarau Ost – Verzweigung Birrfeld – Bauherrenunterstützung

Industries:

Services: