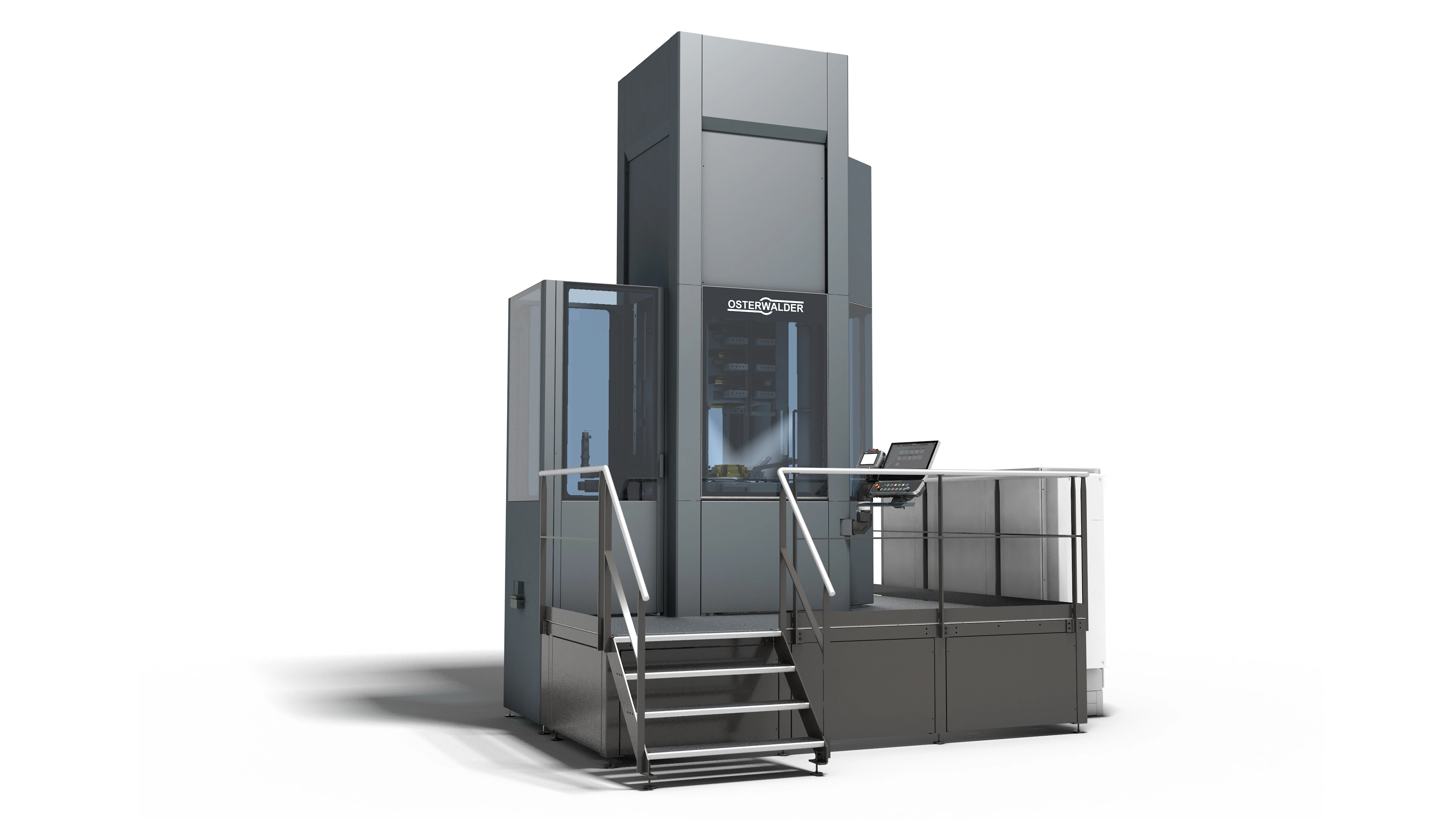

REFERENCE PROJECT

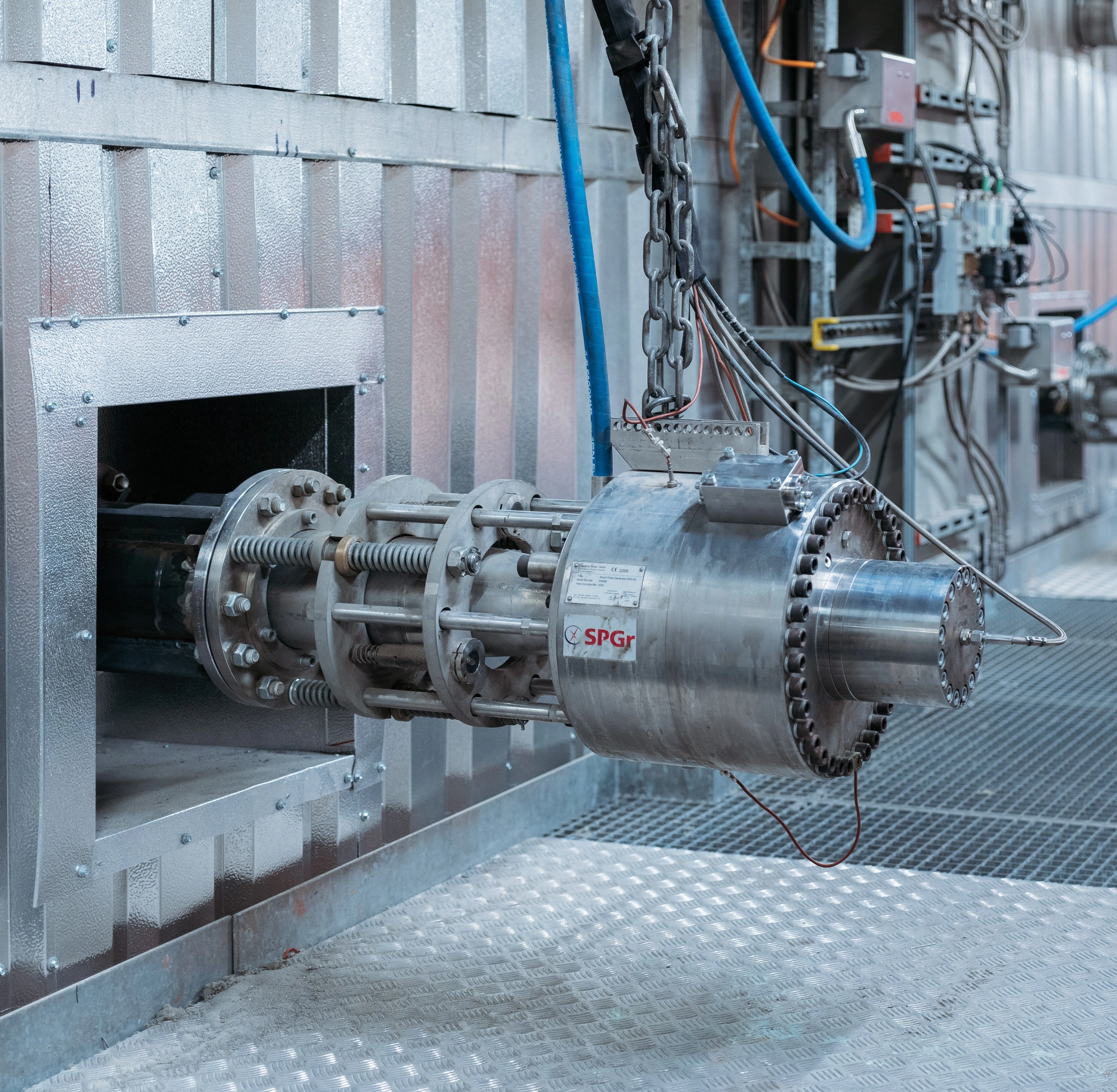

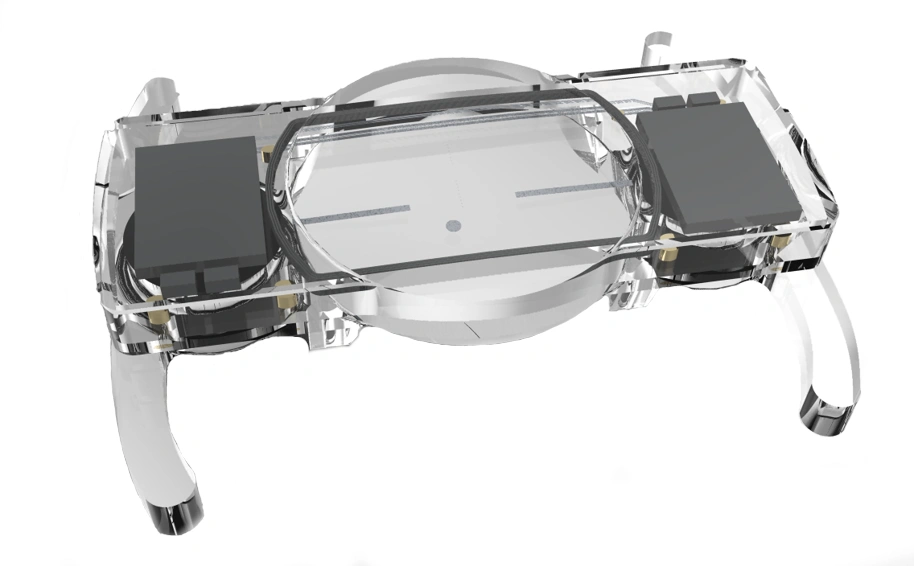

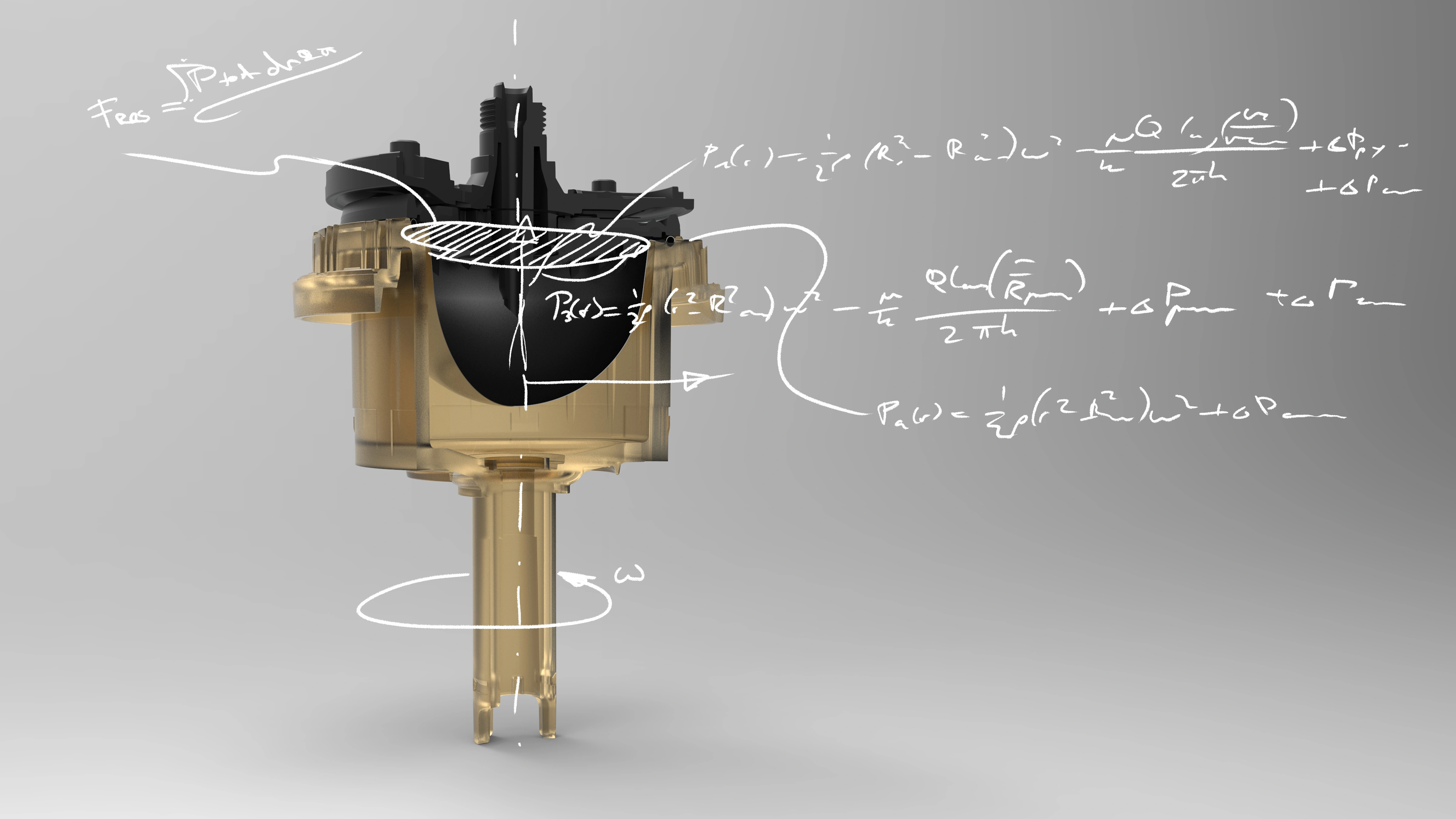

Pacojet 4

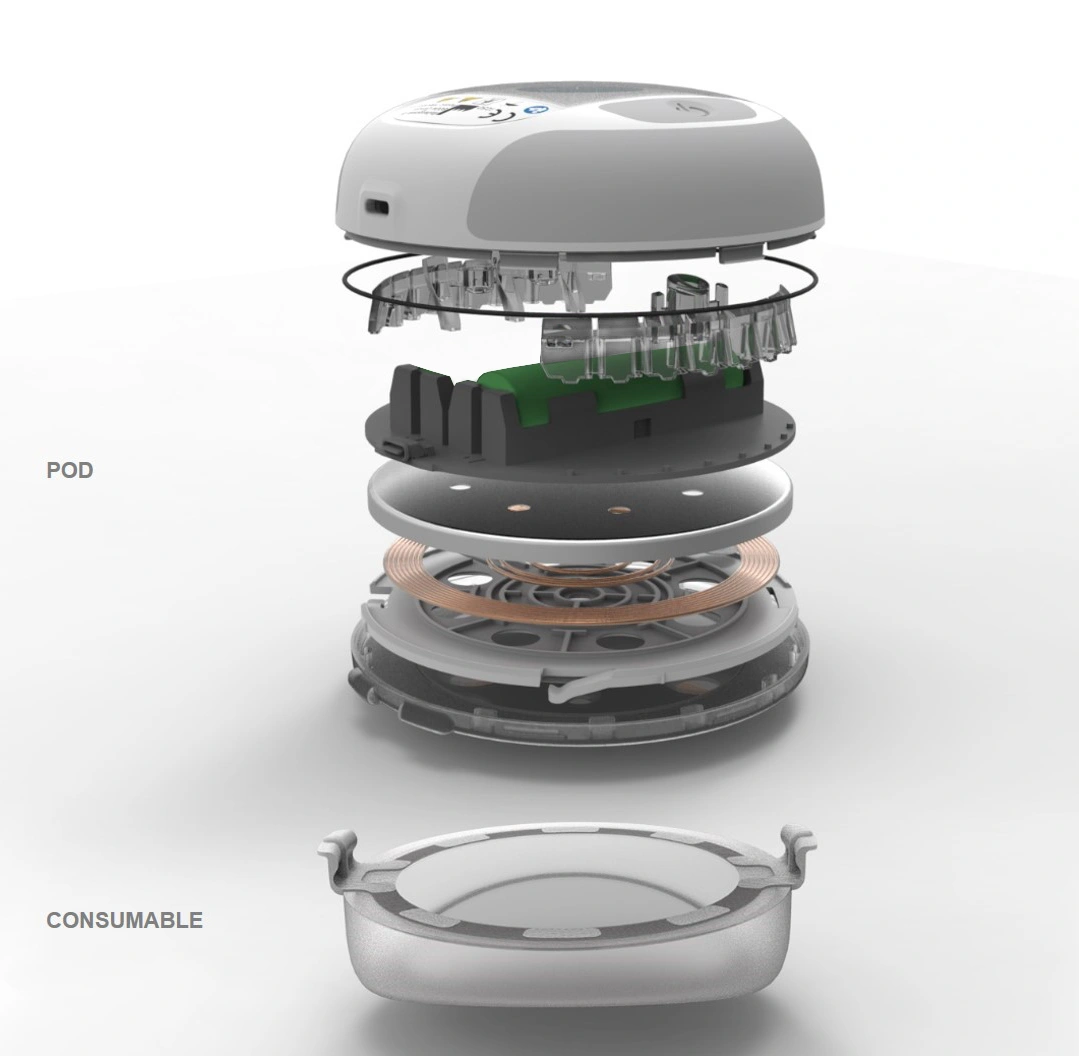

In top gastronomy, a Pacojet® is used in almost every kitchen. Seasonal fresh ingredients are frozen with additional liquid in a beaker and the required portions are later pacotized® from the frozen mass using the Pacojet®. The result is an ultra-fine mousse that can be used directly for sorbets or for the further processing of sauces, soups, farces, concentrates, doughs, etc. - and thanks to the precise portioning, this is sustainable and cost-effective.

The food service industry has benefited from the reliability and robustness of the appliance for several decades. Pacotizing® is a term that has established itself in successful professional kitchens worldwide.

Our customer wanted to equip the next generation of the appliance with user-oriented operation, a new look, numerous new features and greater flexibility in processing the masses. At the same time, the reliability and robustness of the appliance were to be retained.

Services

Industries

Technologies

Key Figures

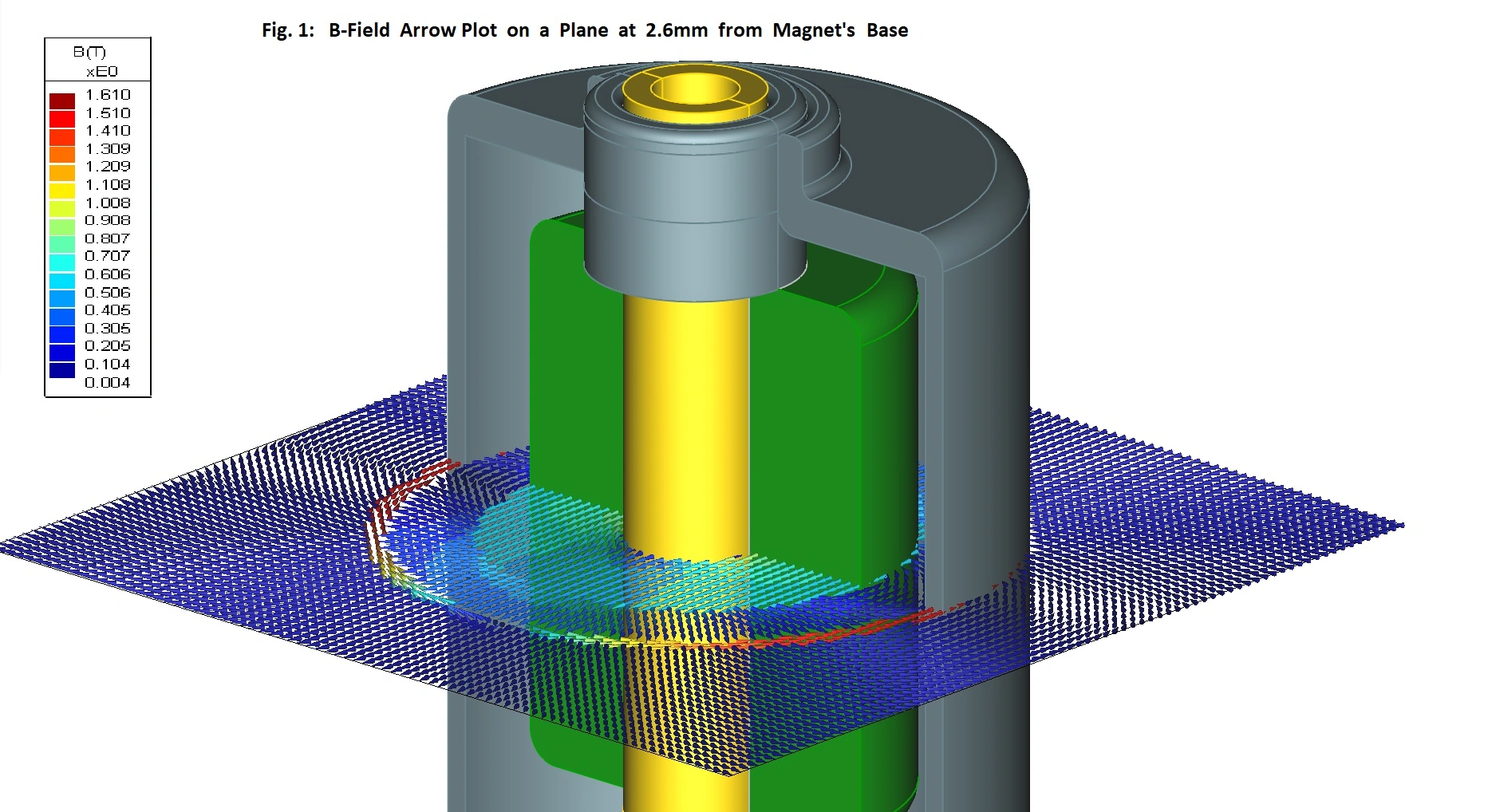

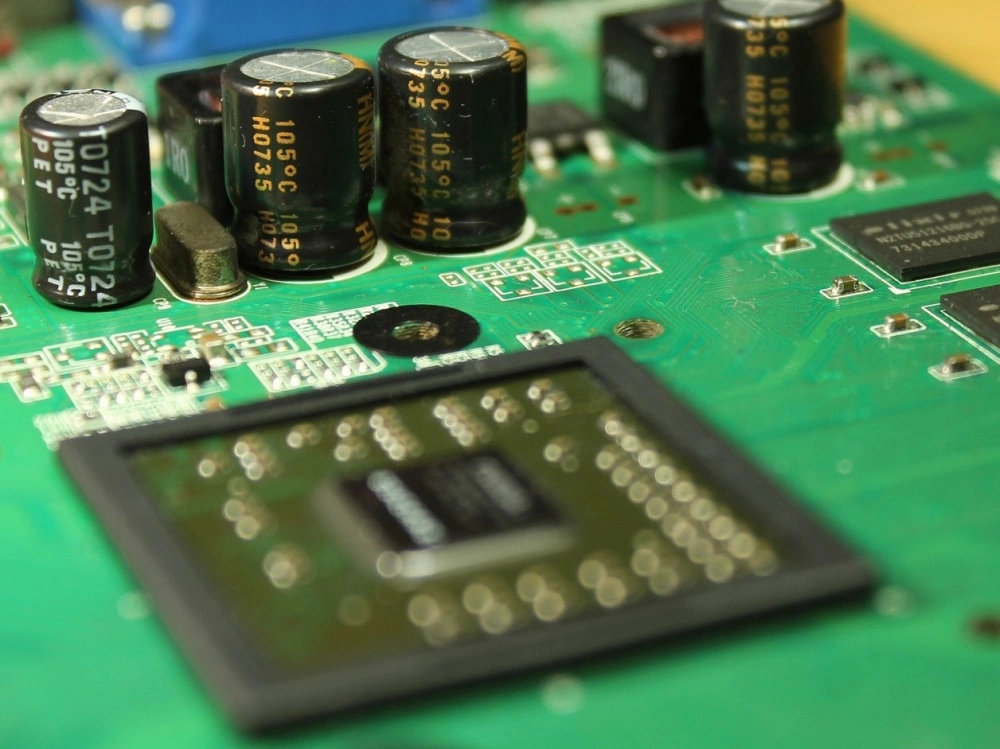

- 1500 watt drive power of two software-synchronized BLDC motors

- Pacotizing® with 1 bar overpressure

- Jet mode with 2.5 times the processing speed

- Reliable function in kitchen environment (grease, water, etc.) of the 7-inch touch screen

- User-friendly operating concept tailored to the professional kitchen

- Recipes can be defined and stored

- Worldwide use

- Wireless data transfer of appliance data to the cloud

- Reproducible results

- Automatic tool recognition

- Energy-saving standby function with fast wake-up on touch

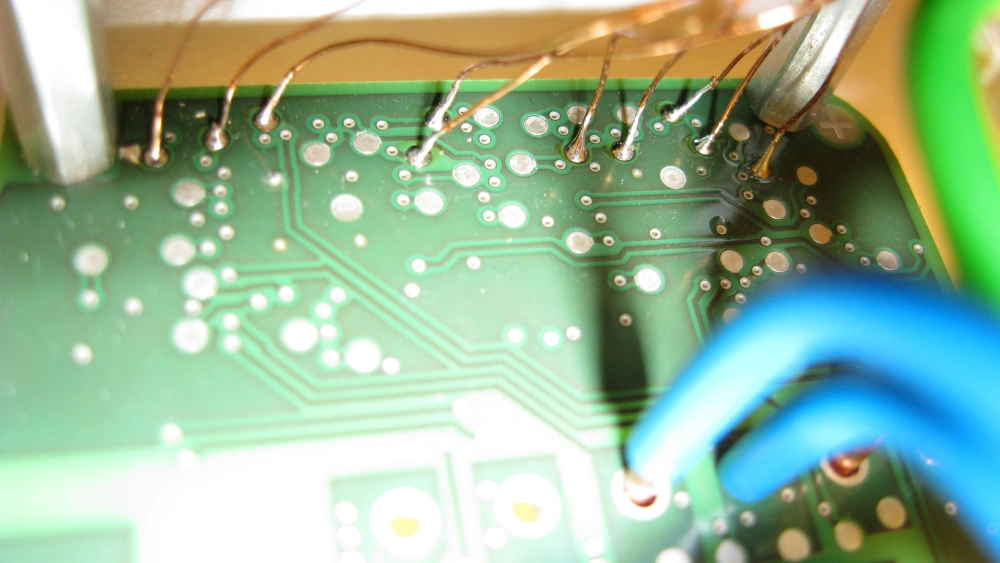

- Durable, serviceable and repairable

Our Contribution

- System development from concept to series production

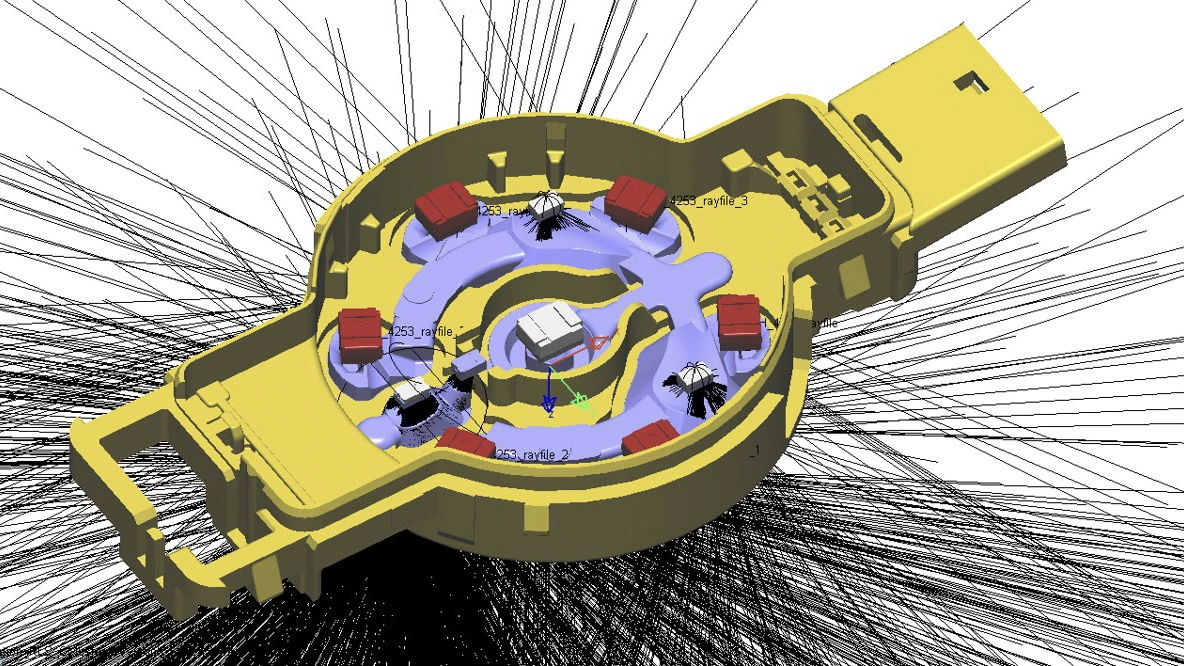

- Development of mechanics, electronics (power & HMI), firmware

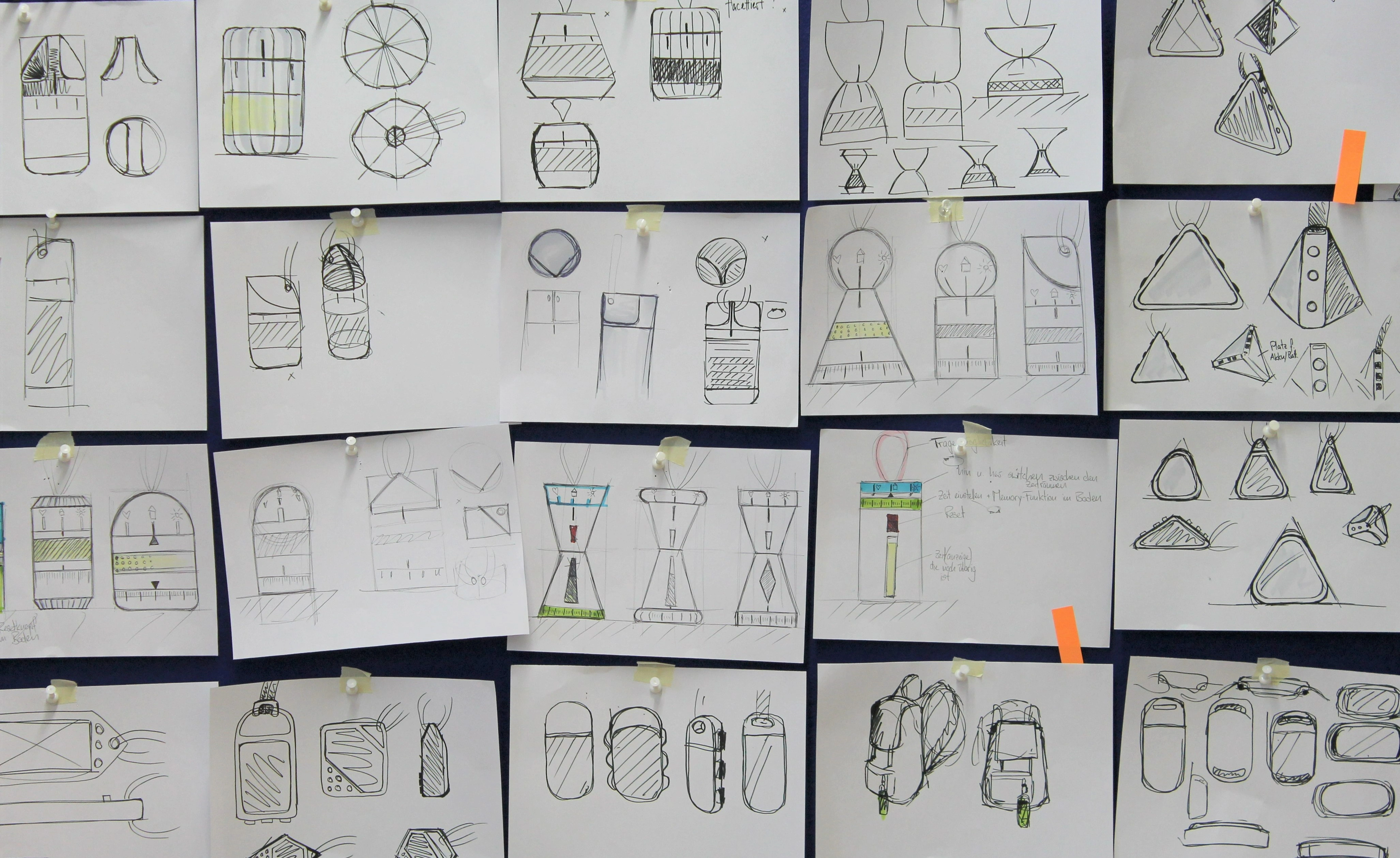

- Development of industrial and UX design

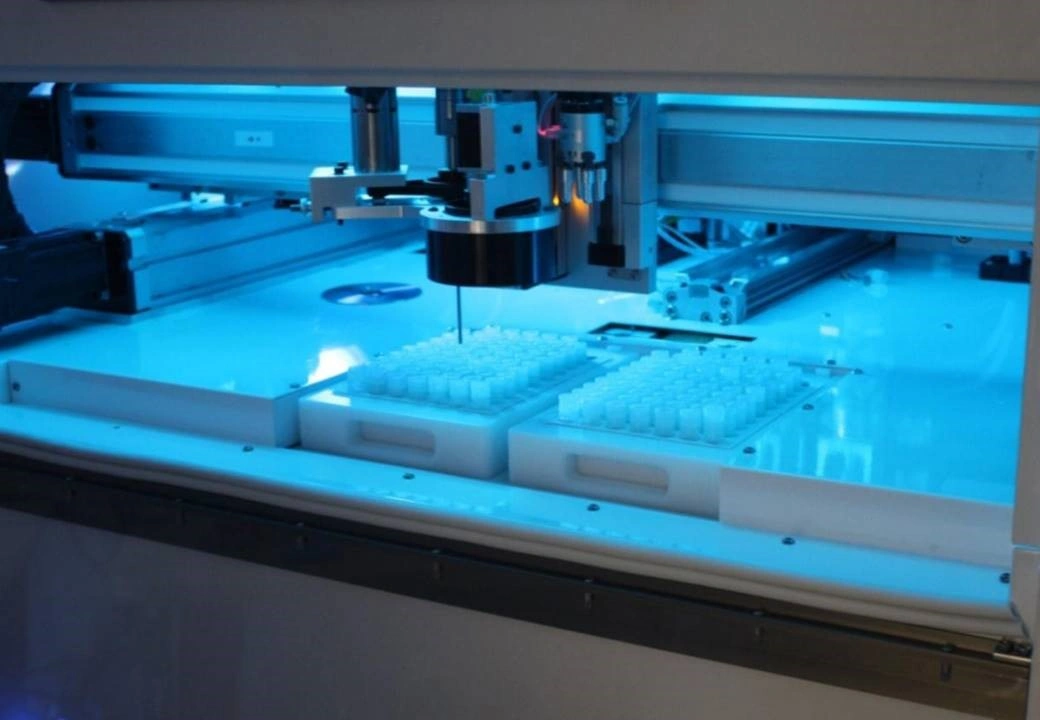

- Procurement, commissioning and testing of functional samples and prototypes

- Support evaluation of system supplier

- Developing endurance test benches and carrying out endurance tests

- Testing prototypes, 0-series and series devices

- Organization and support of conformity assessment (NSF, radio, EMC, safety)

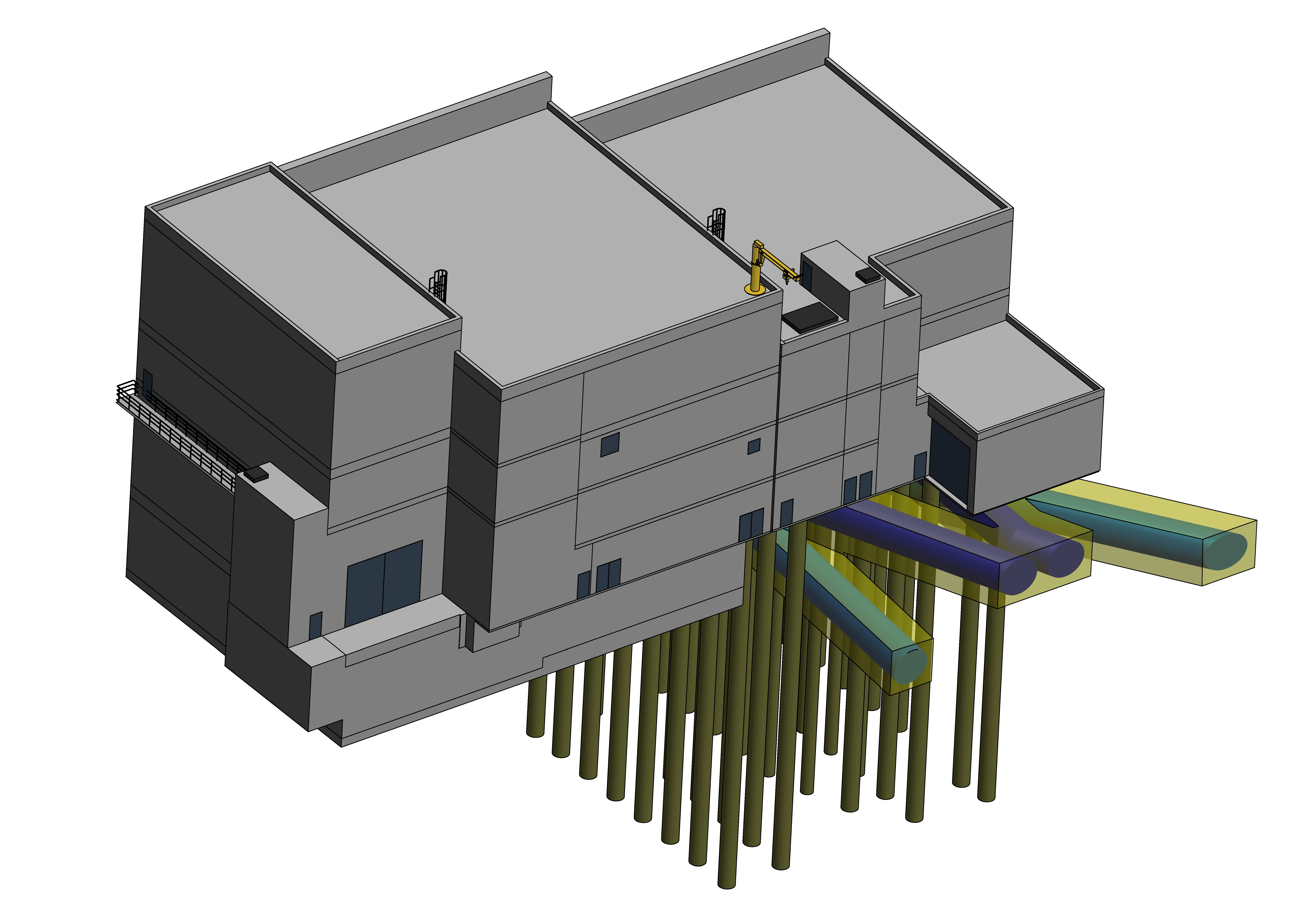

- Support in setting up series production

- Product Life Cycle Management

Outcome

Helbling developed the Pacojet 4® together with the customer until it was ready for series production. Thanks to short decision-making paths, the development from kick-off to the start of production - including conformity assessments and certifications as well as a completely new supply chain - was completed in a short time. Chefs around the world are delighted with the new Pacojet 4®.

Contact

Cases

Internationales Unternehmen der Papierindustrie – Analyse des Dampfsystems

Industries:

Services:

Cases

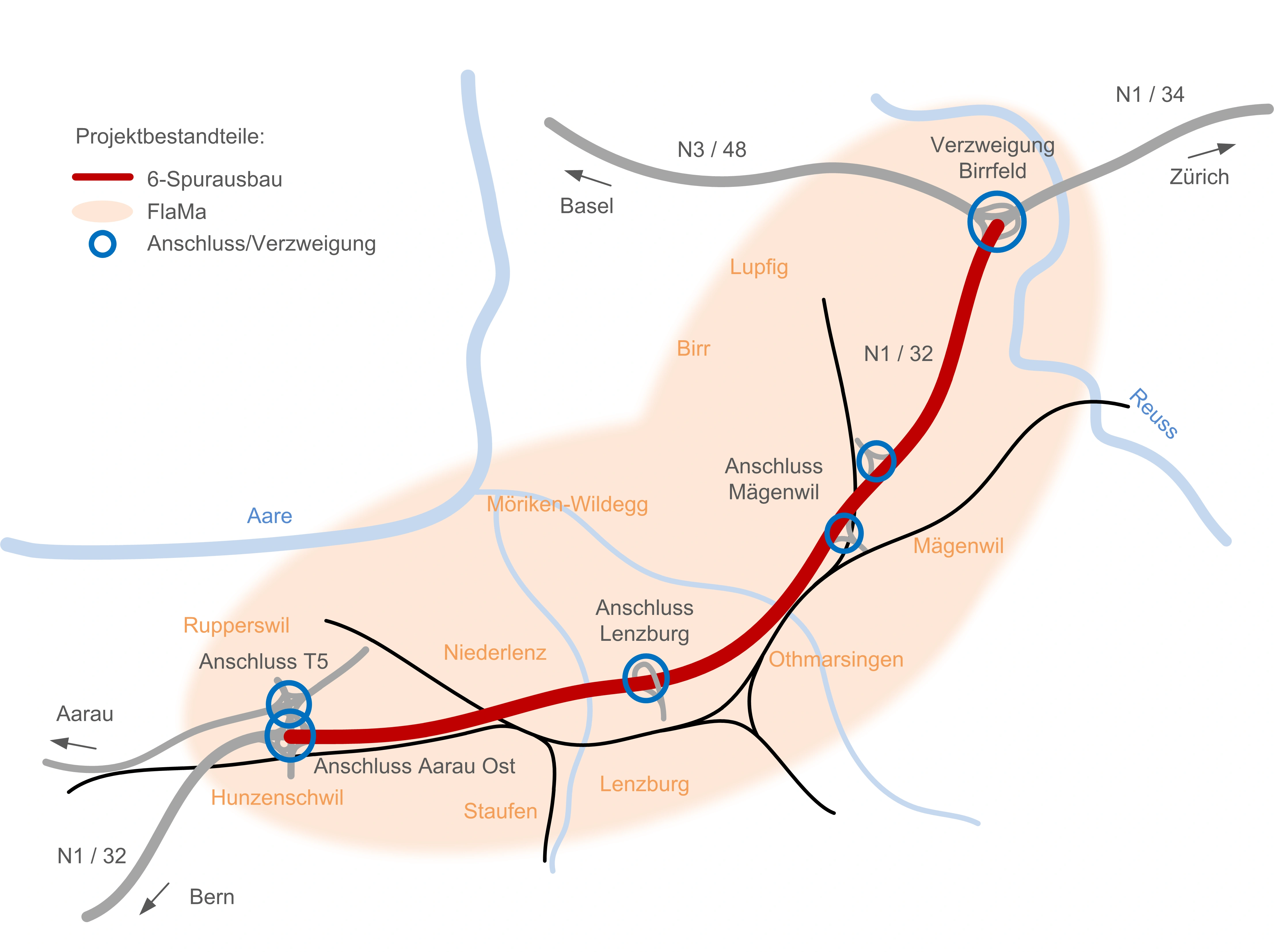

6-Streifenausbau Aarau Ost – Verzweigung Birrfeld – Bauherrenunterstützung

Industries:

Services: