Project

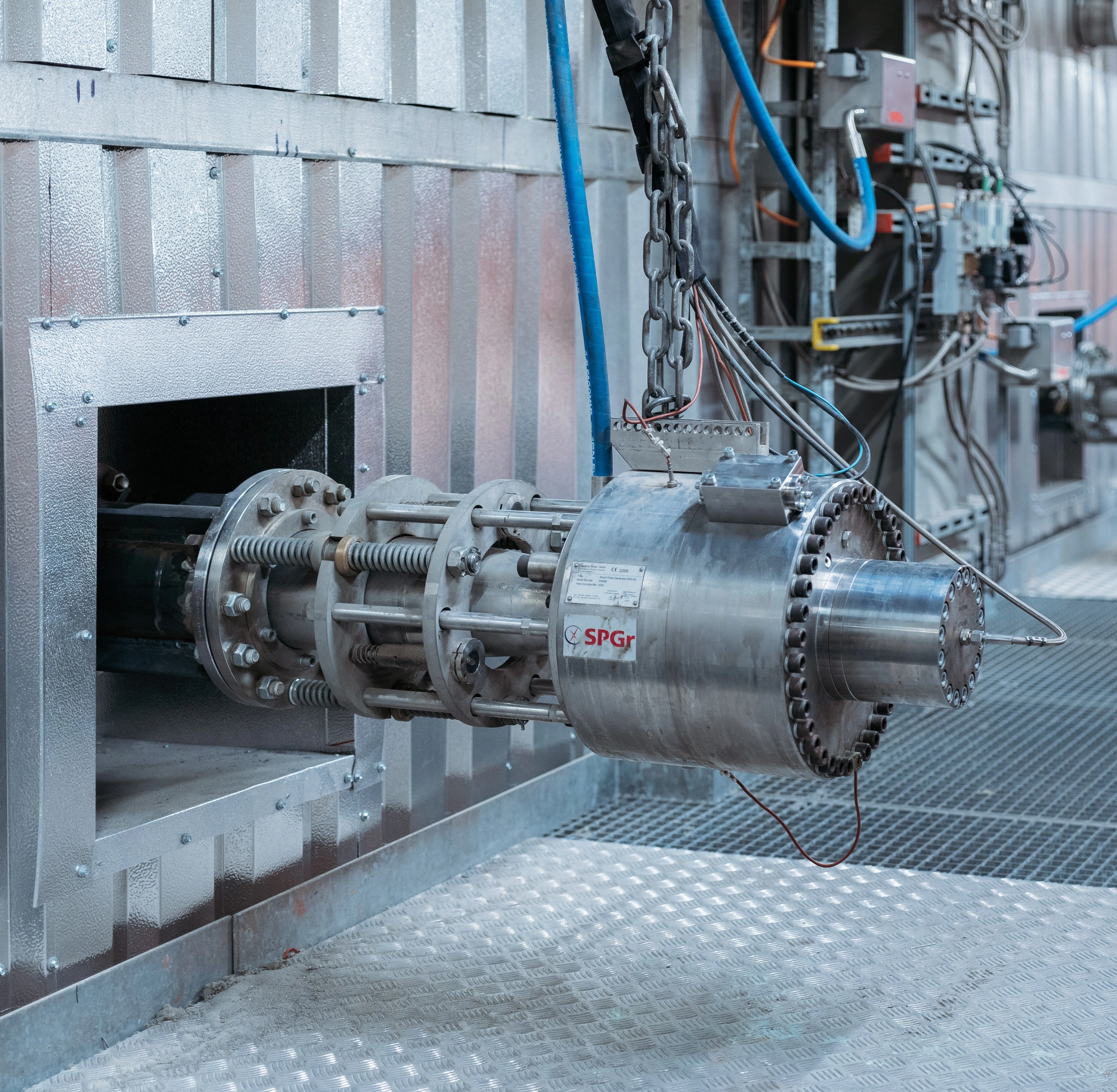

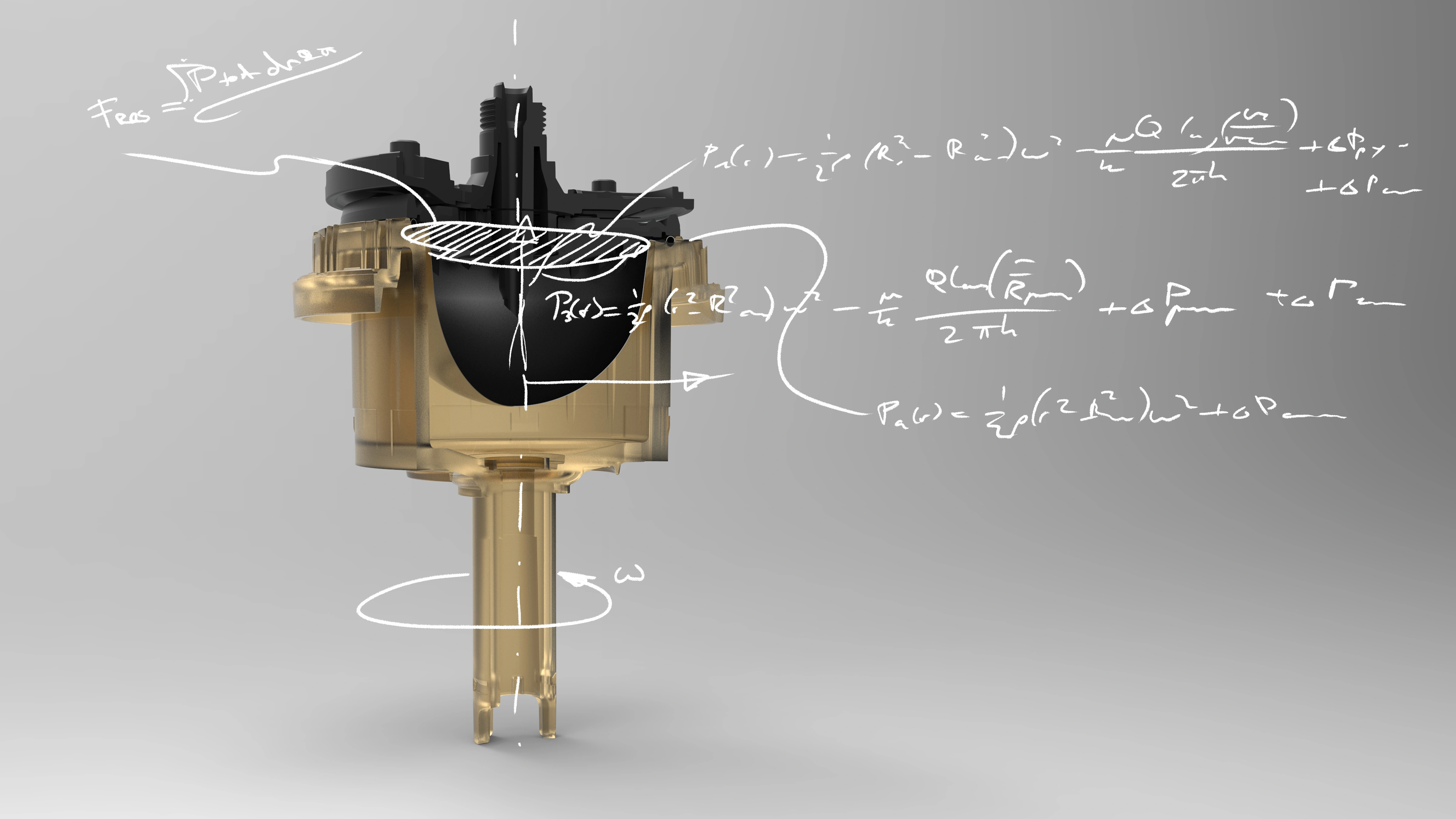

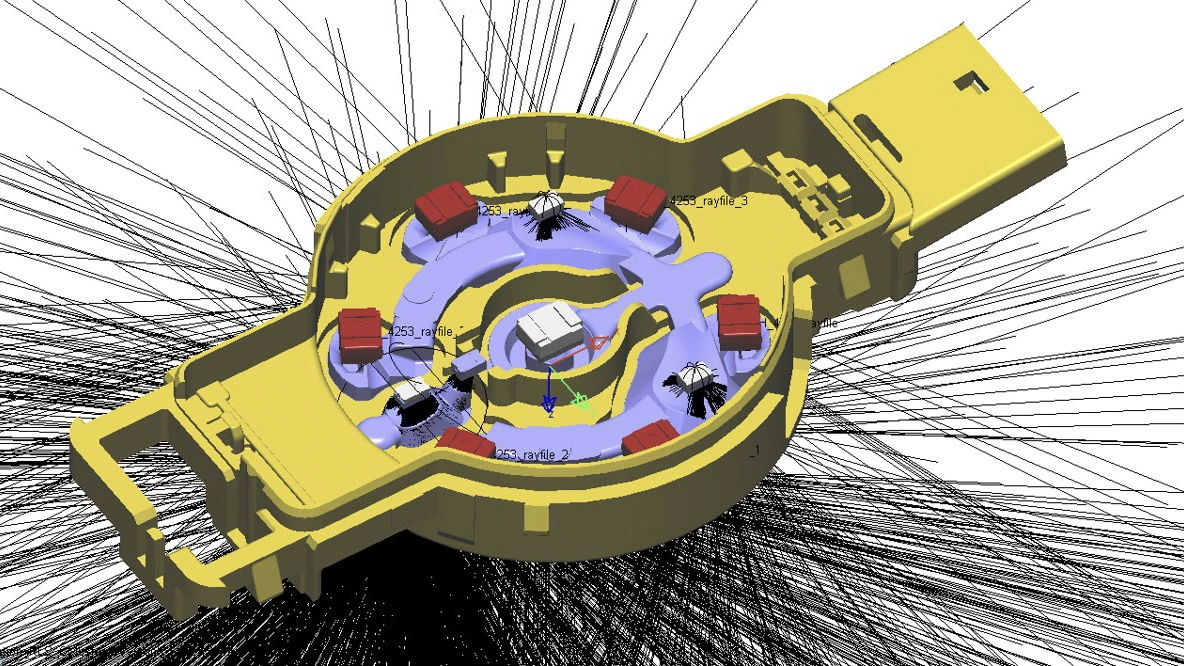

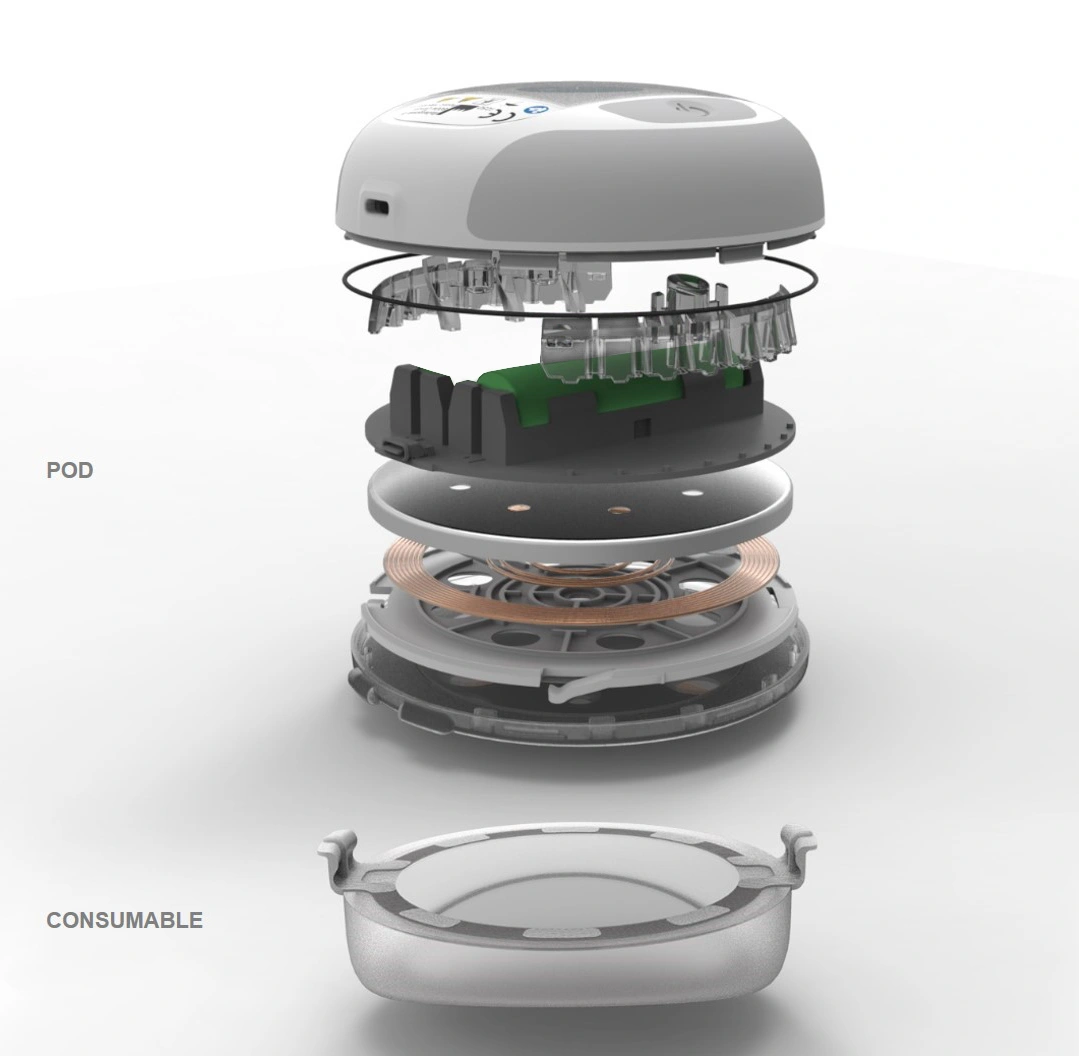

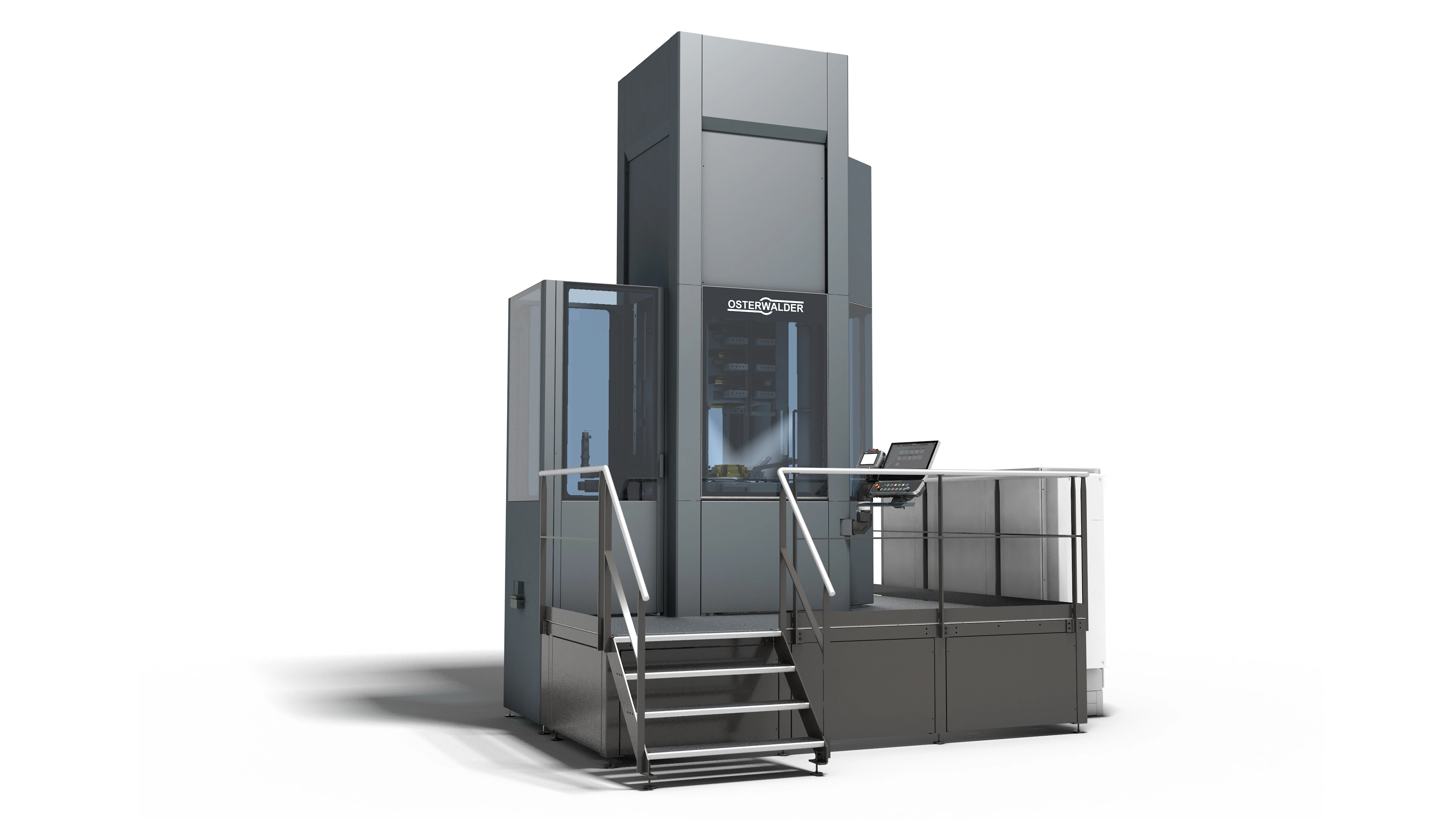

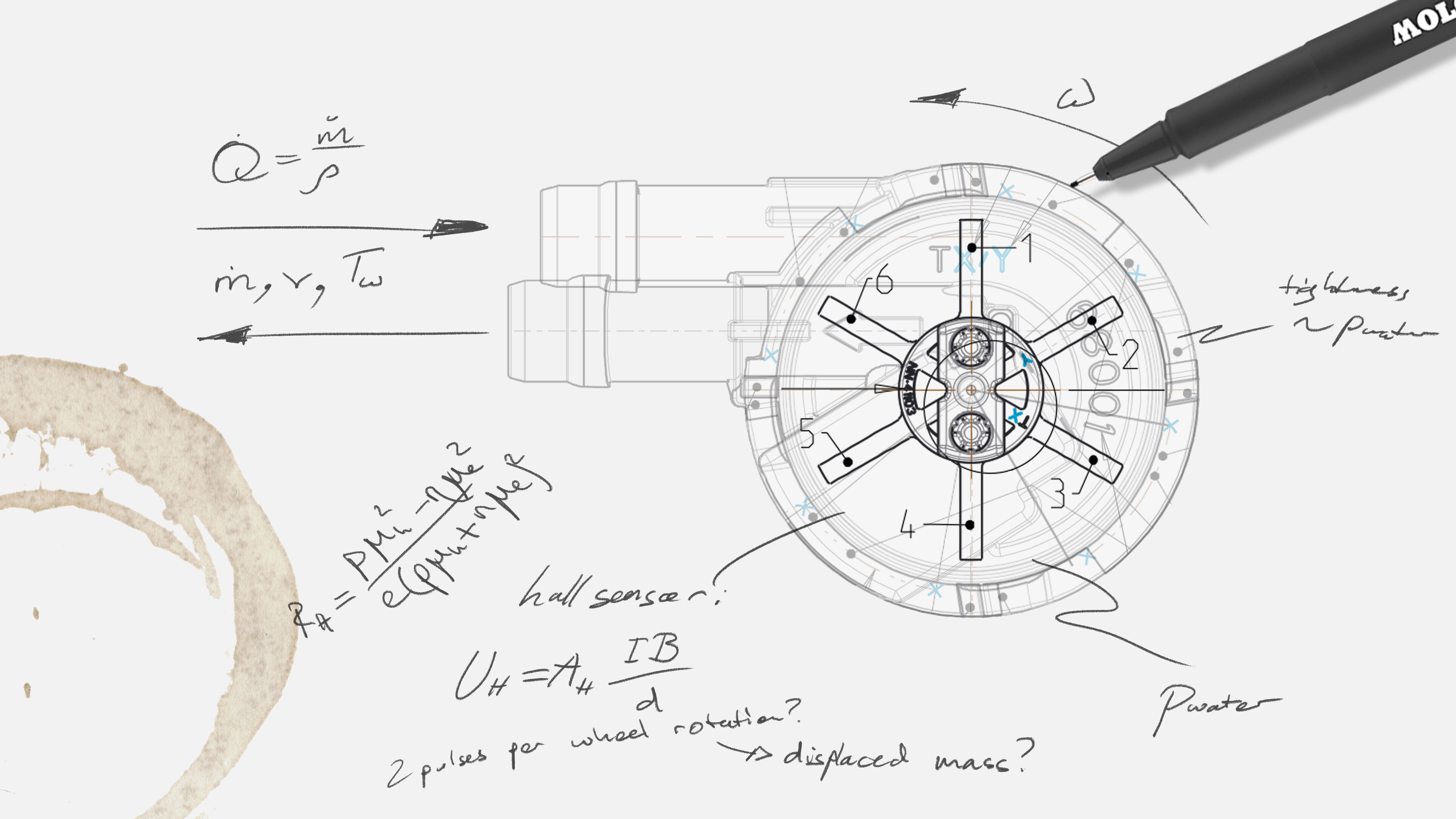

Development of a flow meter

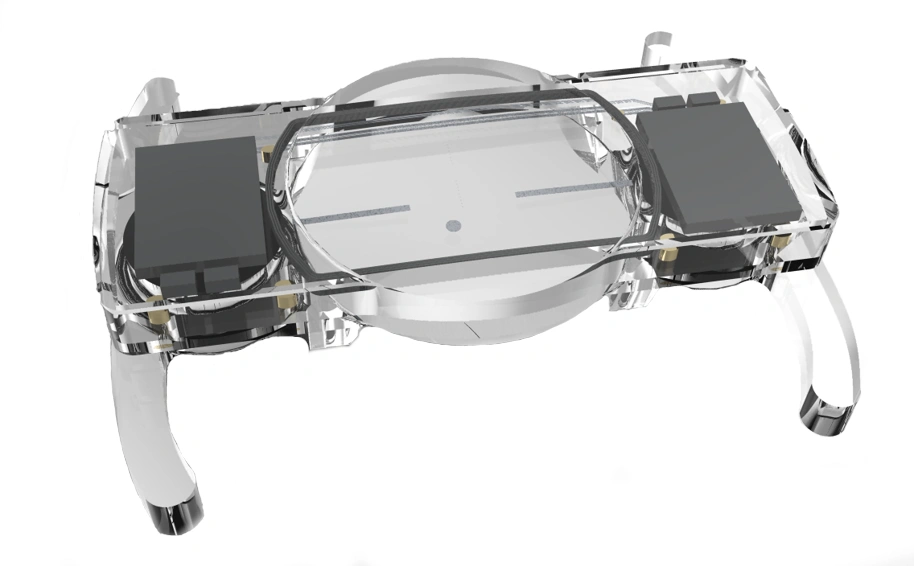

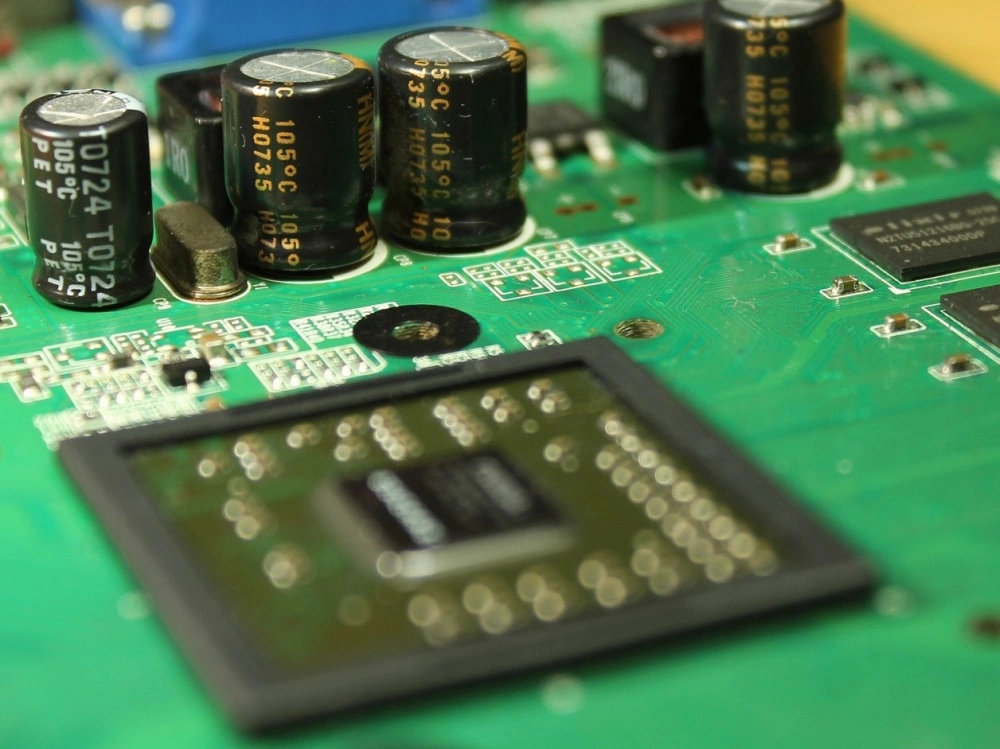

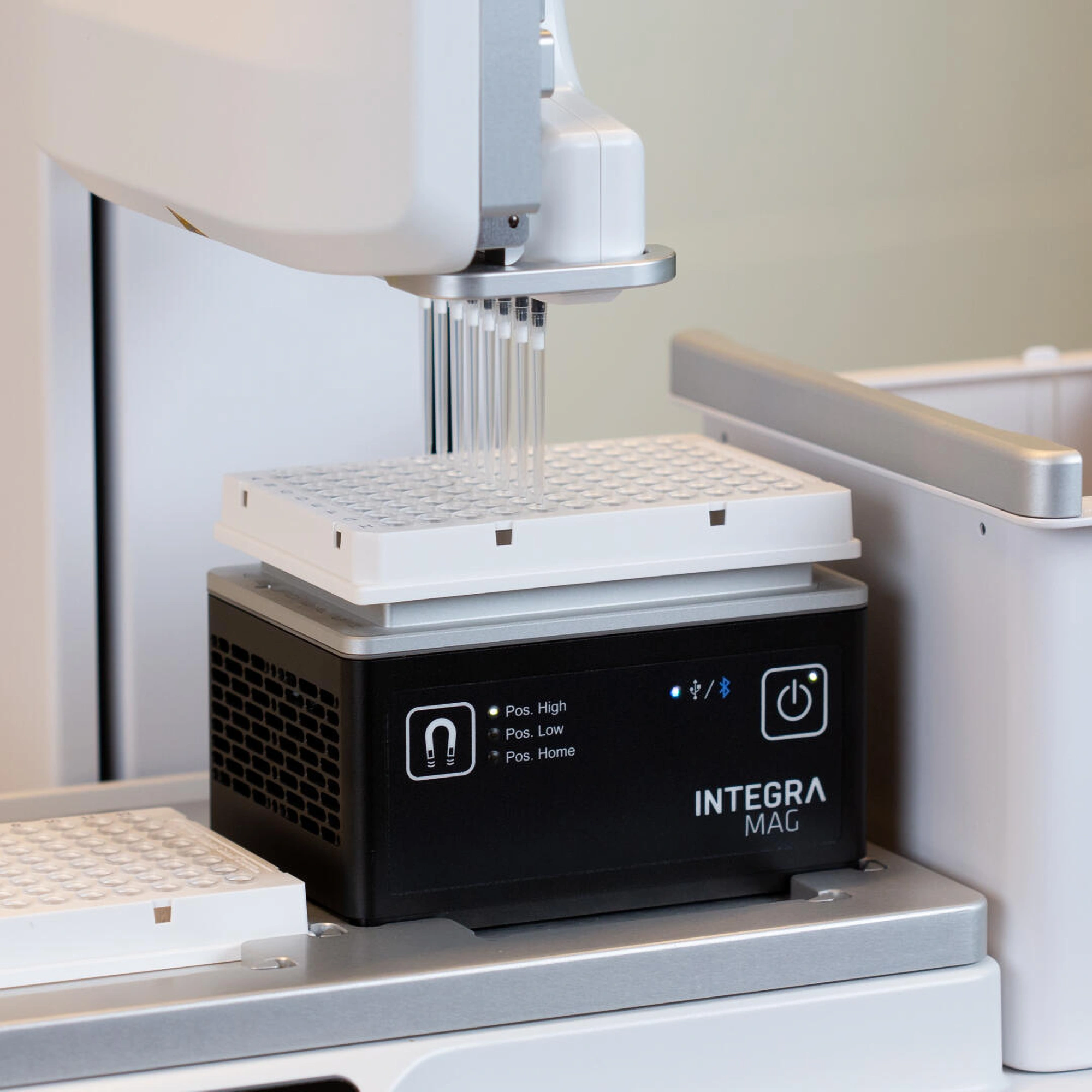

Based on a pilot and technology study, Helbling developed an innovative flow meter until it was ready for series production. Since the device combines small size with functionality in any position, it can be installed flexibly in a variety of different devices (beverage preparation machines).

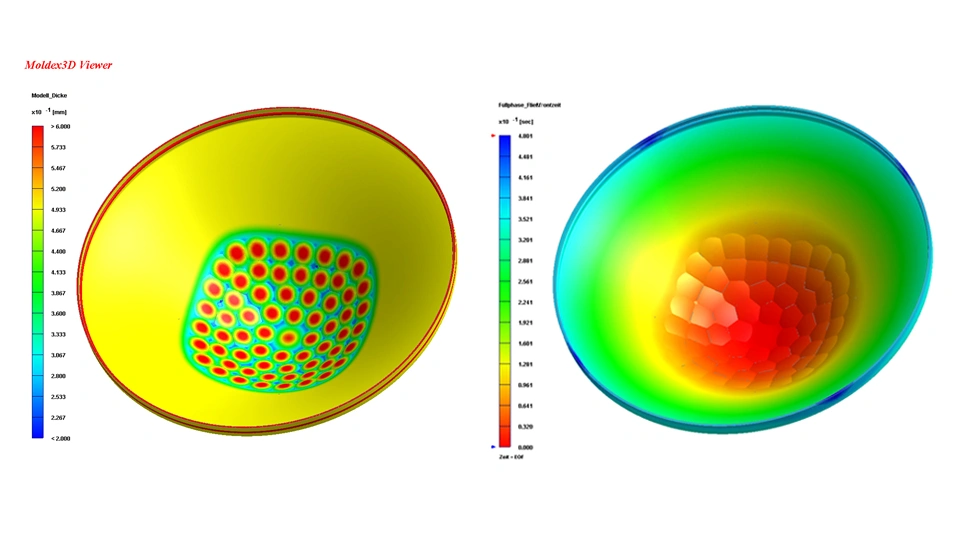

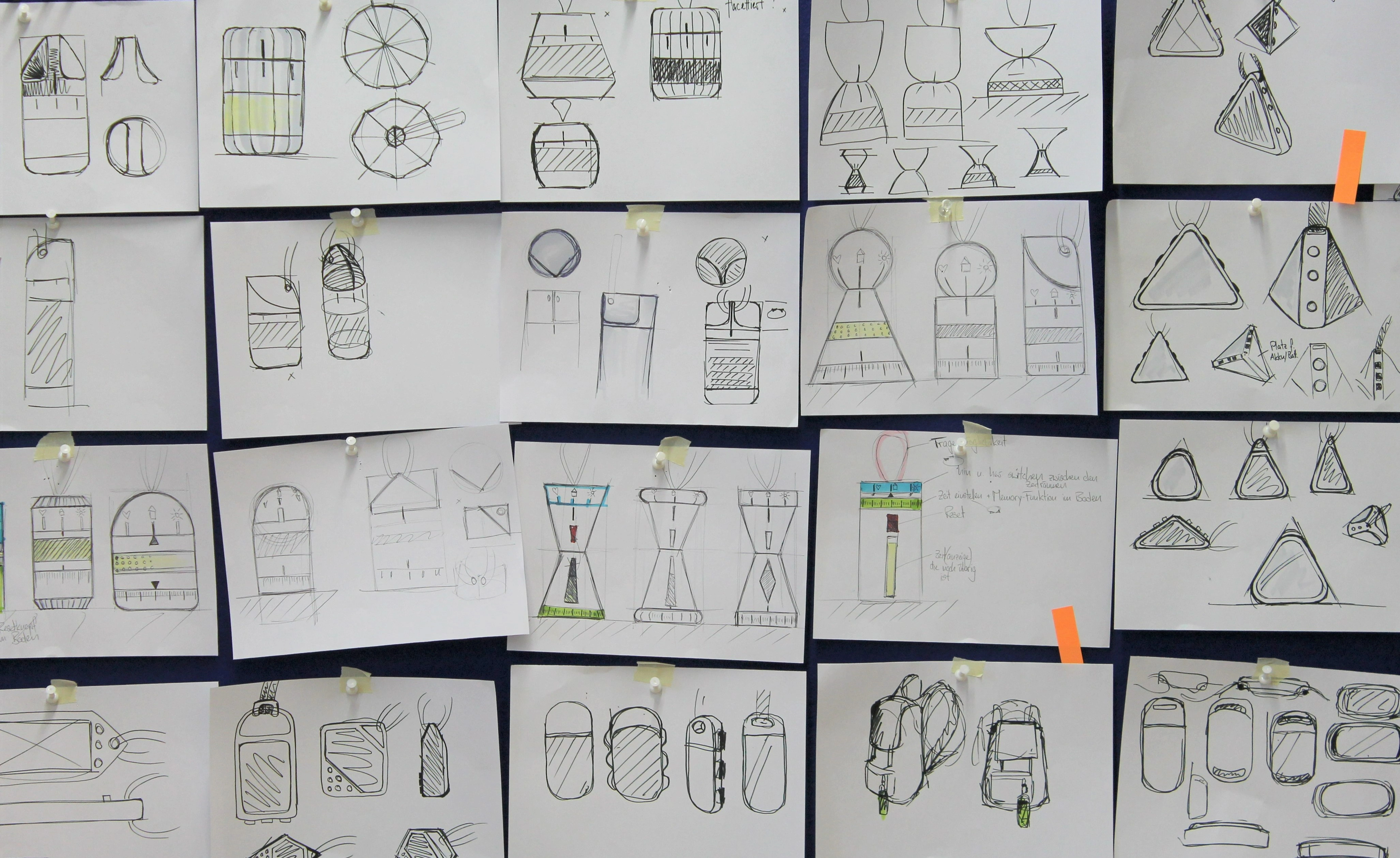

A key lever for cutting production costs lies in the ability to use the same parts and components in a variety of products. With that in mind, a manufacturer of beverage preparation machines commissioned Helbling with the task of developing a single flow meter that could be used in several of its machines. That meant that the flow meter needed to work regardless of which mold cavity the various components were from. "Robust designs" such as this form part of Helbling's proven areas of expertise, which also include the challenging work involved in developing plastic components in tools with multiple mold cavities.

A key lever for cutting production costs lies in the ability to use the same parts and components in a variety of products. With that in mind, a manufacturer of beverage preparation machines commissioned Helbling with the task of developing a single flow meter that could be used in several of its machines. That meant that the flow meter needed to work regardless of which mold cavity the various components were from. "Robust designs" such as this form part of Helbling's proven areas of expertise, which also include the challenging work involved in developing plastic components in tools with multiple mold cavities.

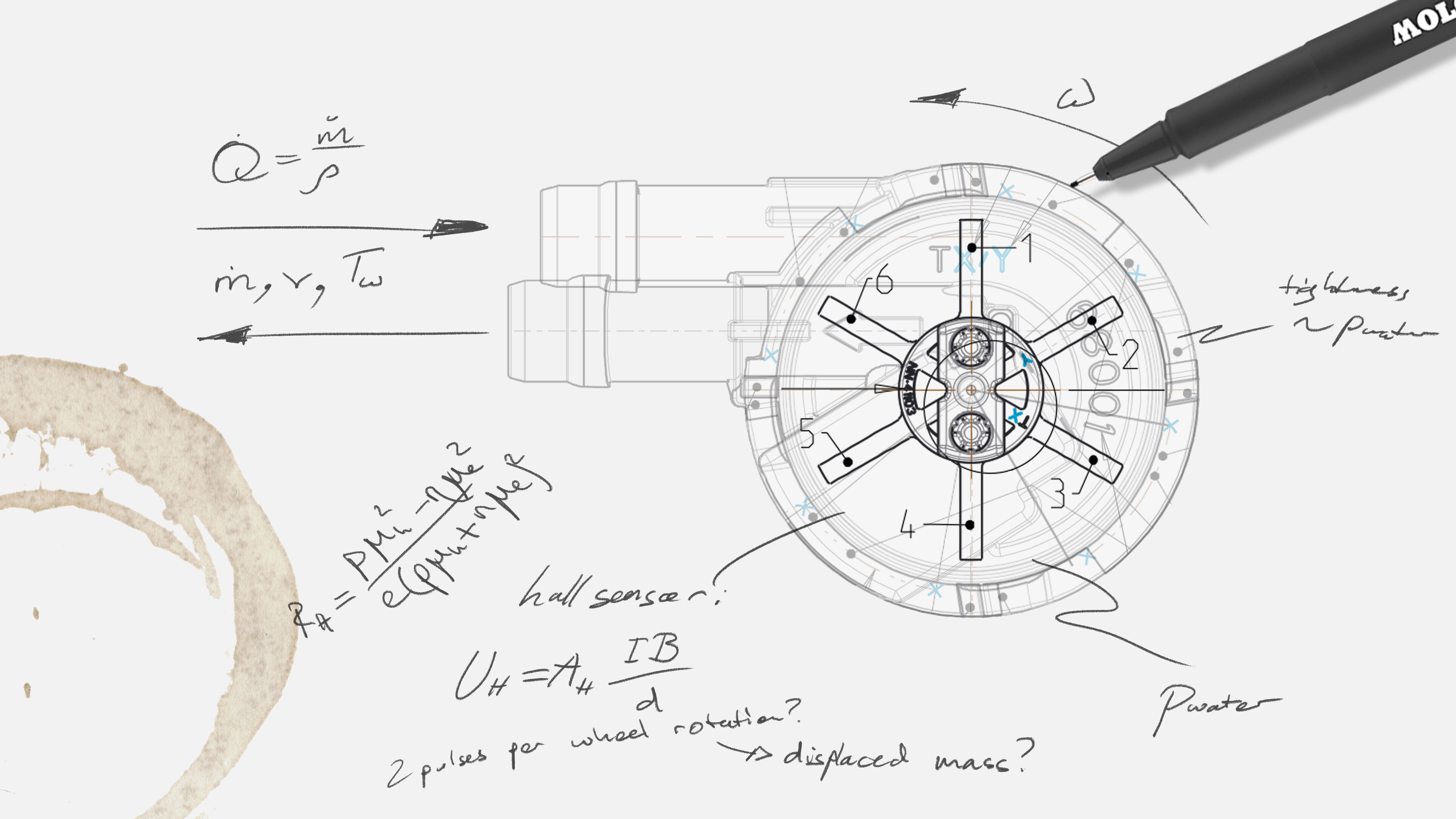

- Compact construction (35 x 25 x 25 mm)

- Position-independent operation

- Measurement range from 0.04 to 0.6 l/min

- Two versions with different electronics interfaces

Services

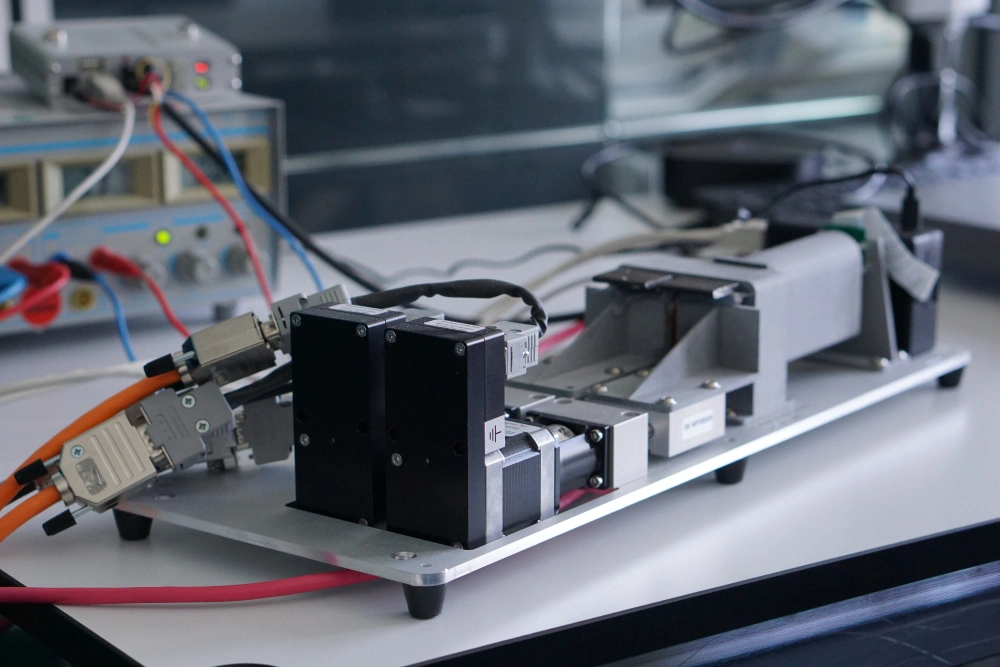

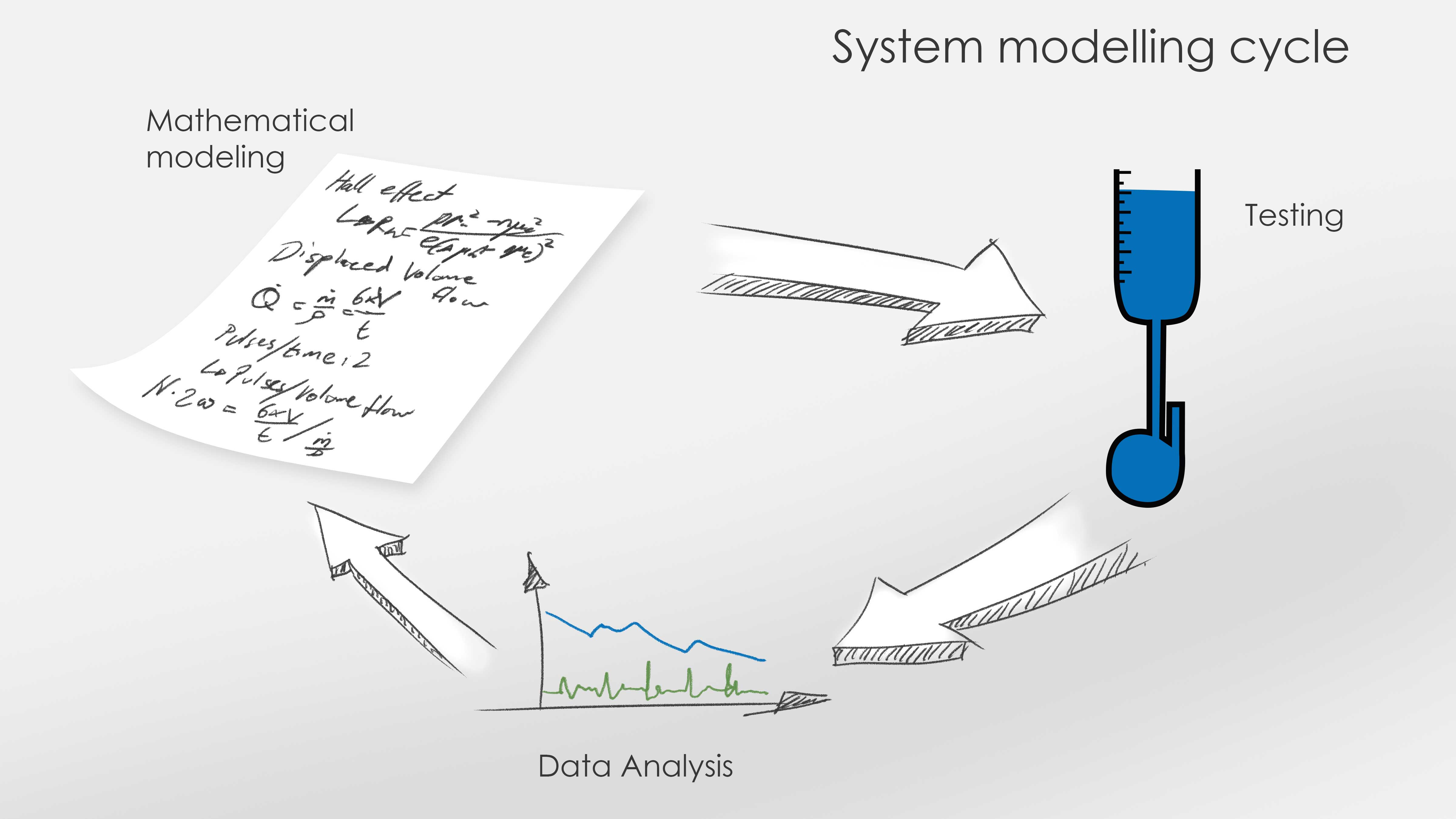

- Technology study and pilot studies for in-house development

- Simplification as primary focus

- Sensor without seal between housing halves as formerly common rubber seals caused imprecise spacing

- Number of parts reduced from 7 to 3

- Significant improvement in system stability

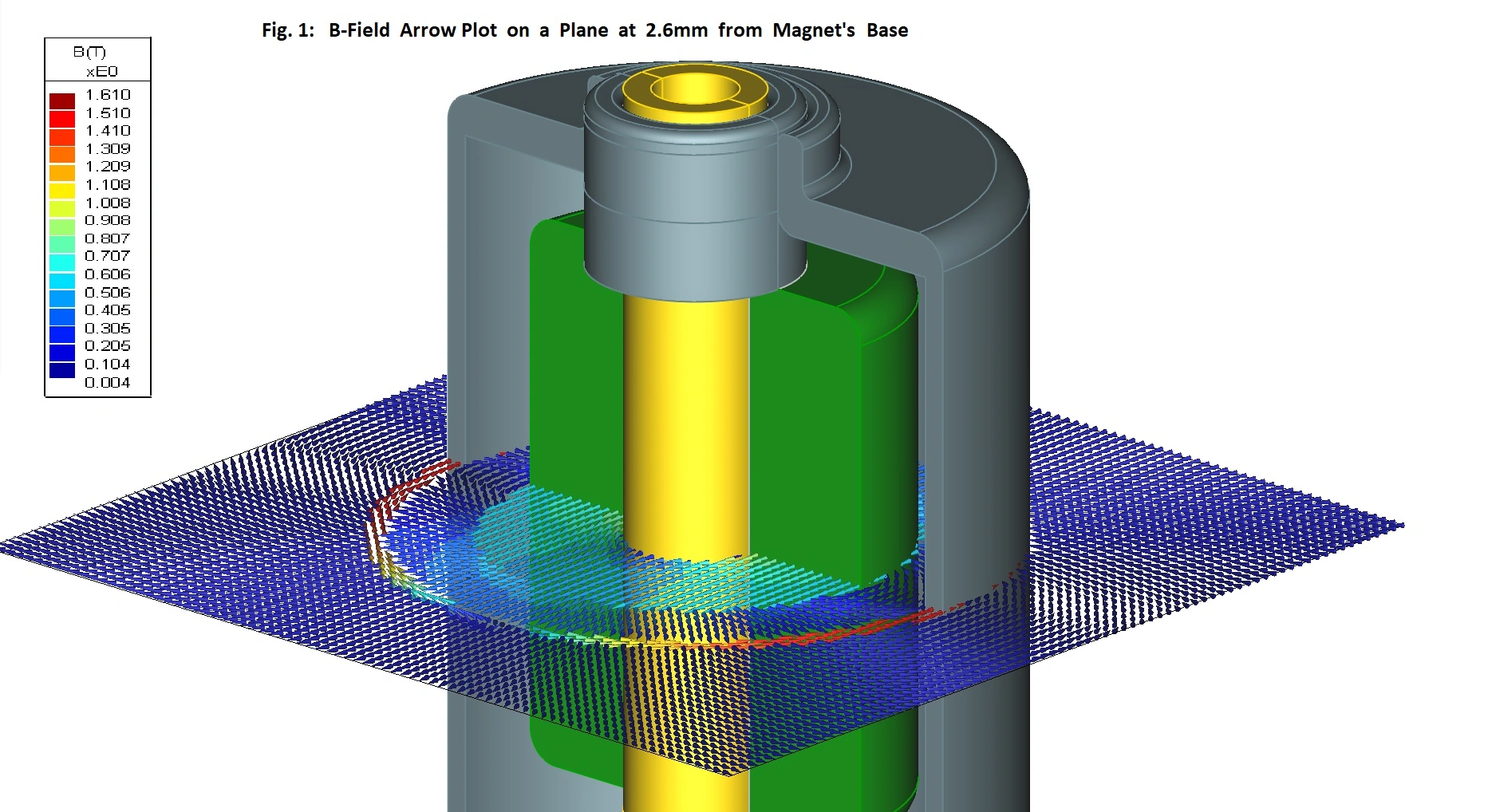

- Knowledge and ability to model system mathematically

- Shorter development time to series production

- Solid interface between sensor and machine

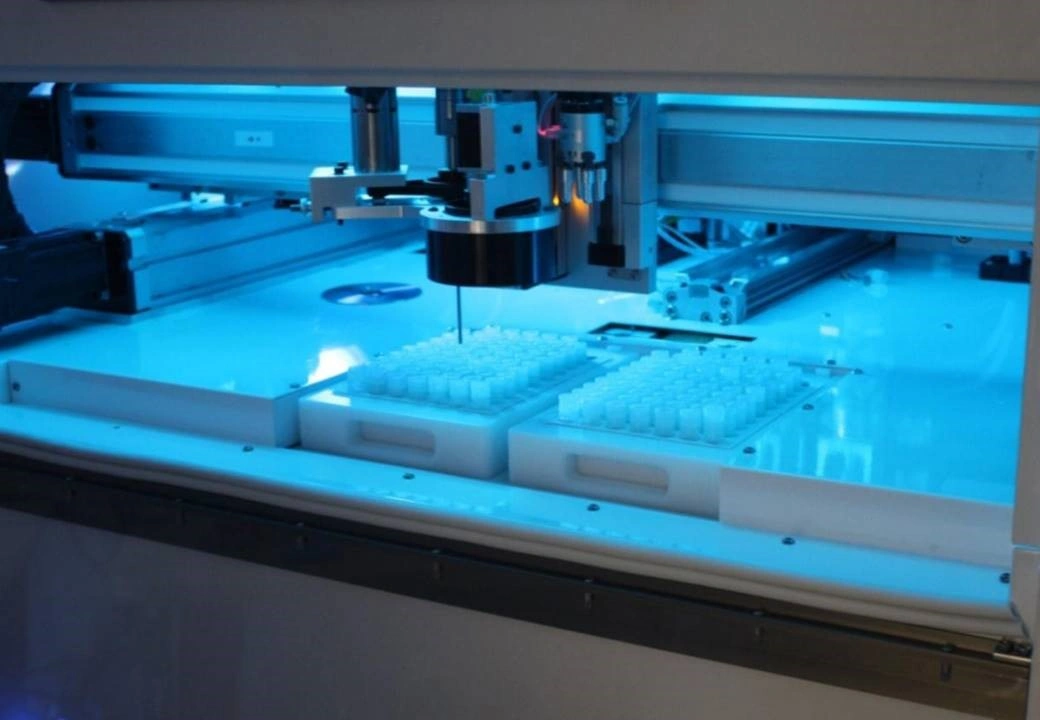

- High requirements for plastics production and automated assembly

Result / Success

Bei diesem Sensor zur Messung der Durchflussmenge handelt es sich um eine Komponente, die der Auftragsgeber ausschliesslich für eigene Produkte verwendet.

Cases

Internationales Unternehmen der Papierindustrie – Analyse des Dampfsystems

Industries:

Services:

Cases

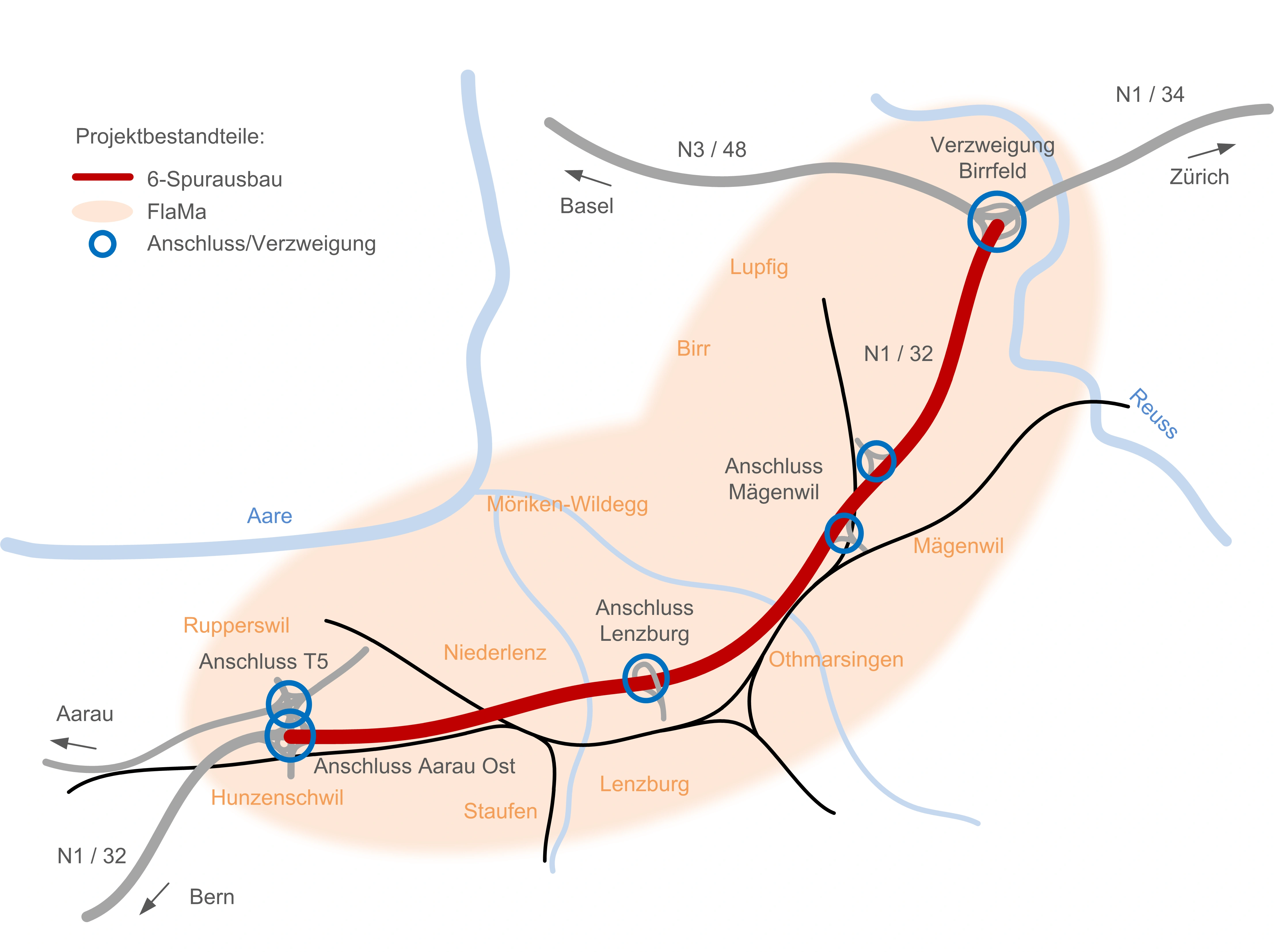

6-Streifenausbau Aarau Ost – Verzweigung Birrfeld – Bauherrenunterstützung

Industries:

Services: