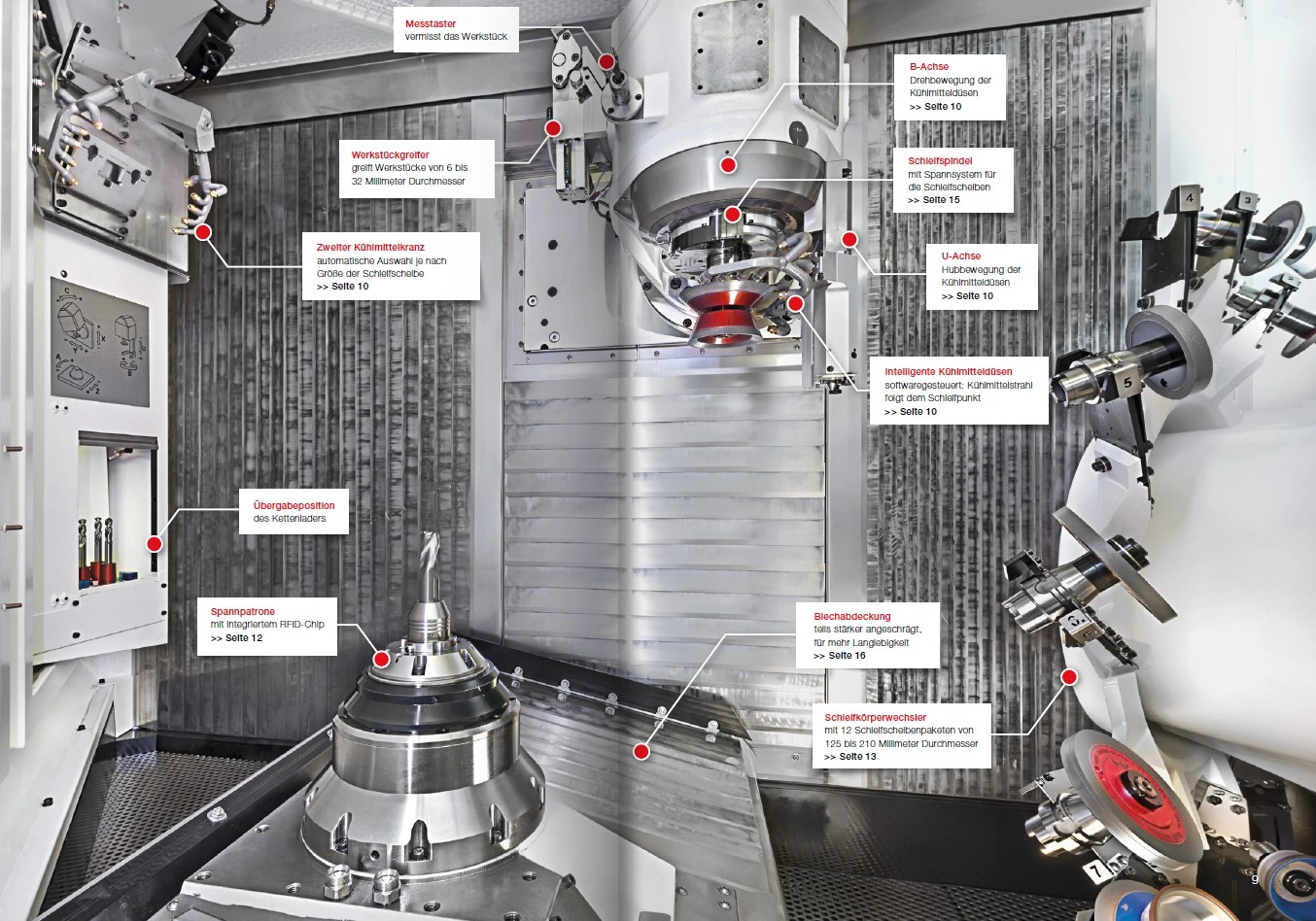

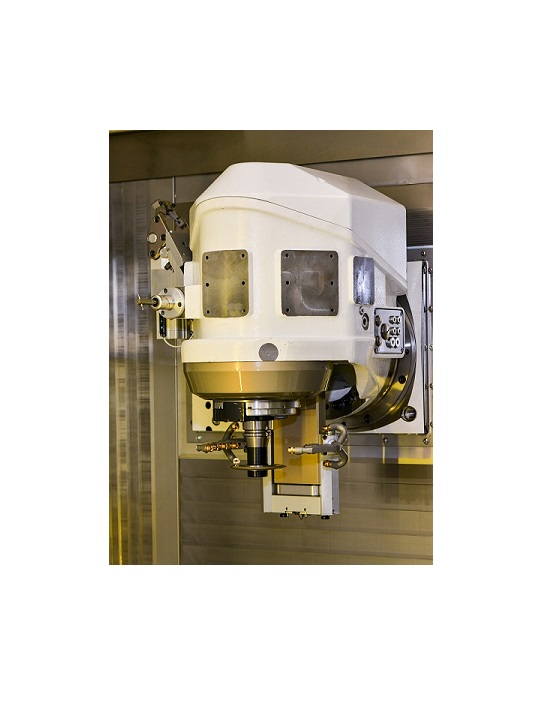

The ISOG 24 tool grinding machine is able to produce or regrind tools such as drills and all types of special tools with a defined cutting edge. Helbling Technik developed the machine in cooperation with our customer – starting from the analysis of the predecessor model right through to assisting in the launch stage.

CNC grinding centers readjust cutting tools by machining or sharpening them. Based on an existing grinding machine, ISOG approached Helbling with some optimization points. The main aspects were to improve quality and machine reliability. The modified grinding wheel changer and addition of an innovative coolant nozzle reduce throughput times and create significant added value for the end customer. At the AMB in Stuttgart, ISOG 24 was presented to specialist world for the first time and successfully demonstrated.

Key Figures

- Grinding head with 12,000 rpm

- Grinding wheel changer with 12 grinding wheel packages from 125 to 210 mm in diameter

- Software-controlled coolant nozzle that follows the grinding point

- Small footprint: 2,850 mm x 2,000 mm

- Fast tool change with 10 s chip-to-chip time

- Up to 80 % reduced consumption of coolant

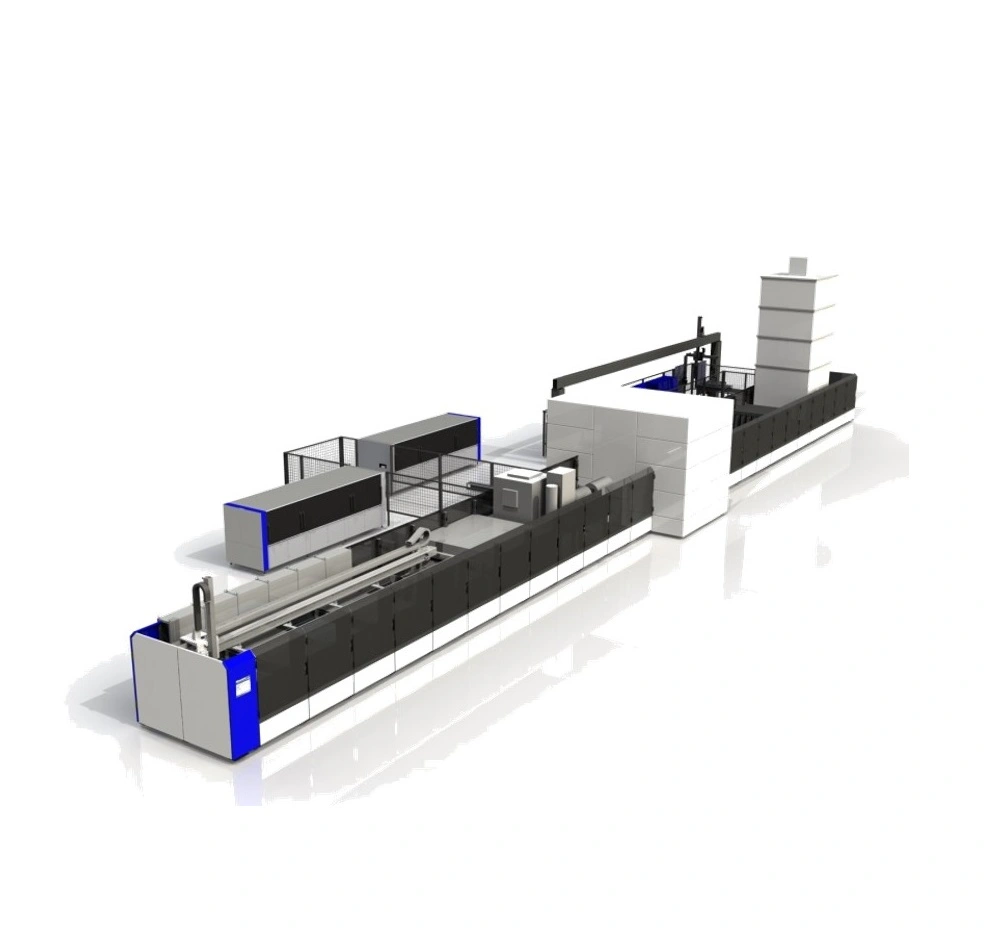

- Modular system for customized automation

Our Contribution

- Develop the new ISOG 24 tool grinding machine, focusing on market and customer-relevant improvements

- Implement collected optimization points from the predecessor machines

- Improve quality and machine reliability

- Short throughput time and systematic approach