- Requirements management

- Quality engineering in development

- FMEA

- DFMA

- Tolerance analysis

- Design to cost

- Test planning

- DOE

- Test definition

- Data acquisition & processing

- Reliability engineering

- System understanding

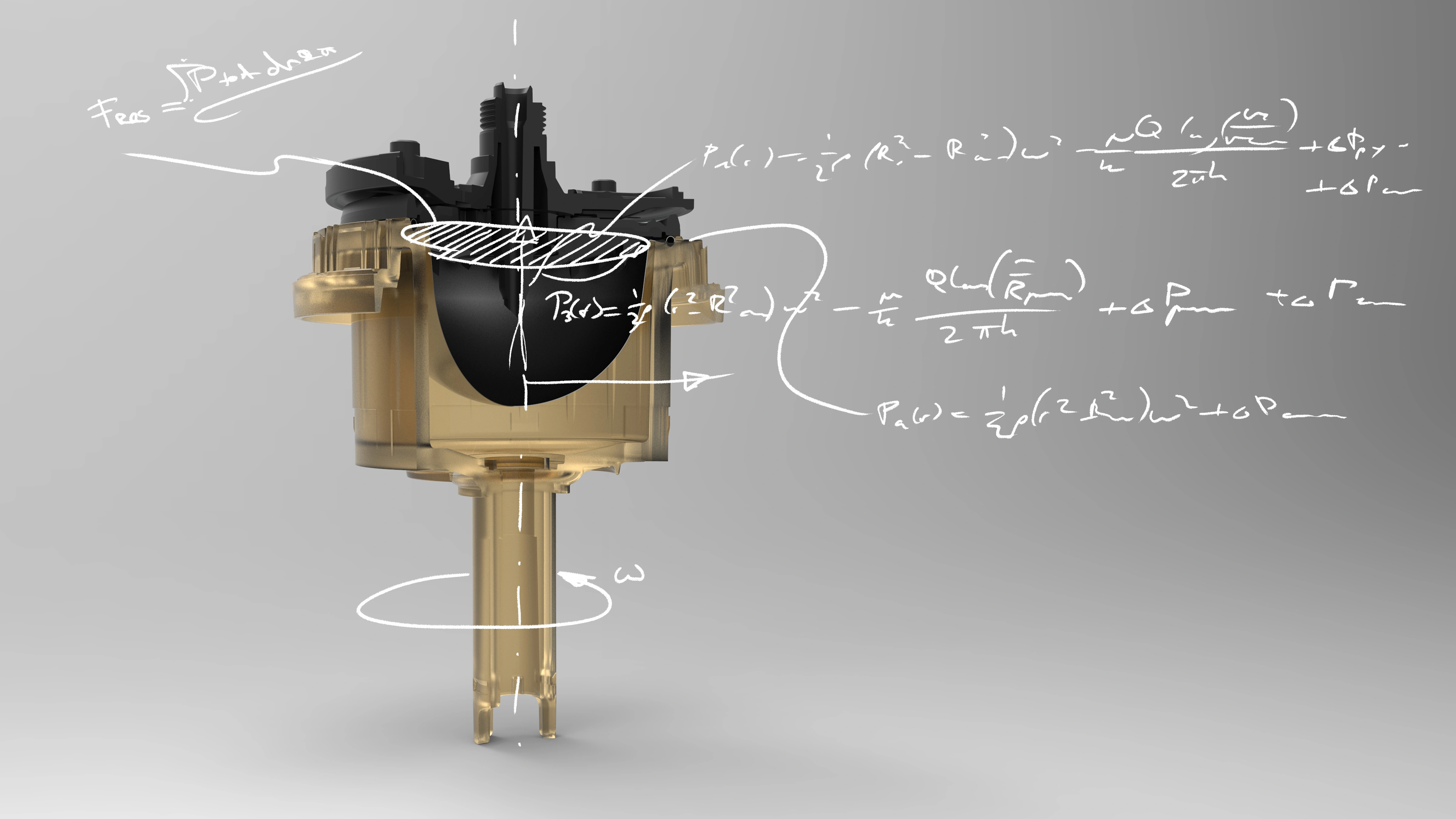

- Physical modeling of mechanical, thermal, hydraulic, and pneumatic processes

service

Detailed Design

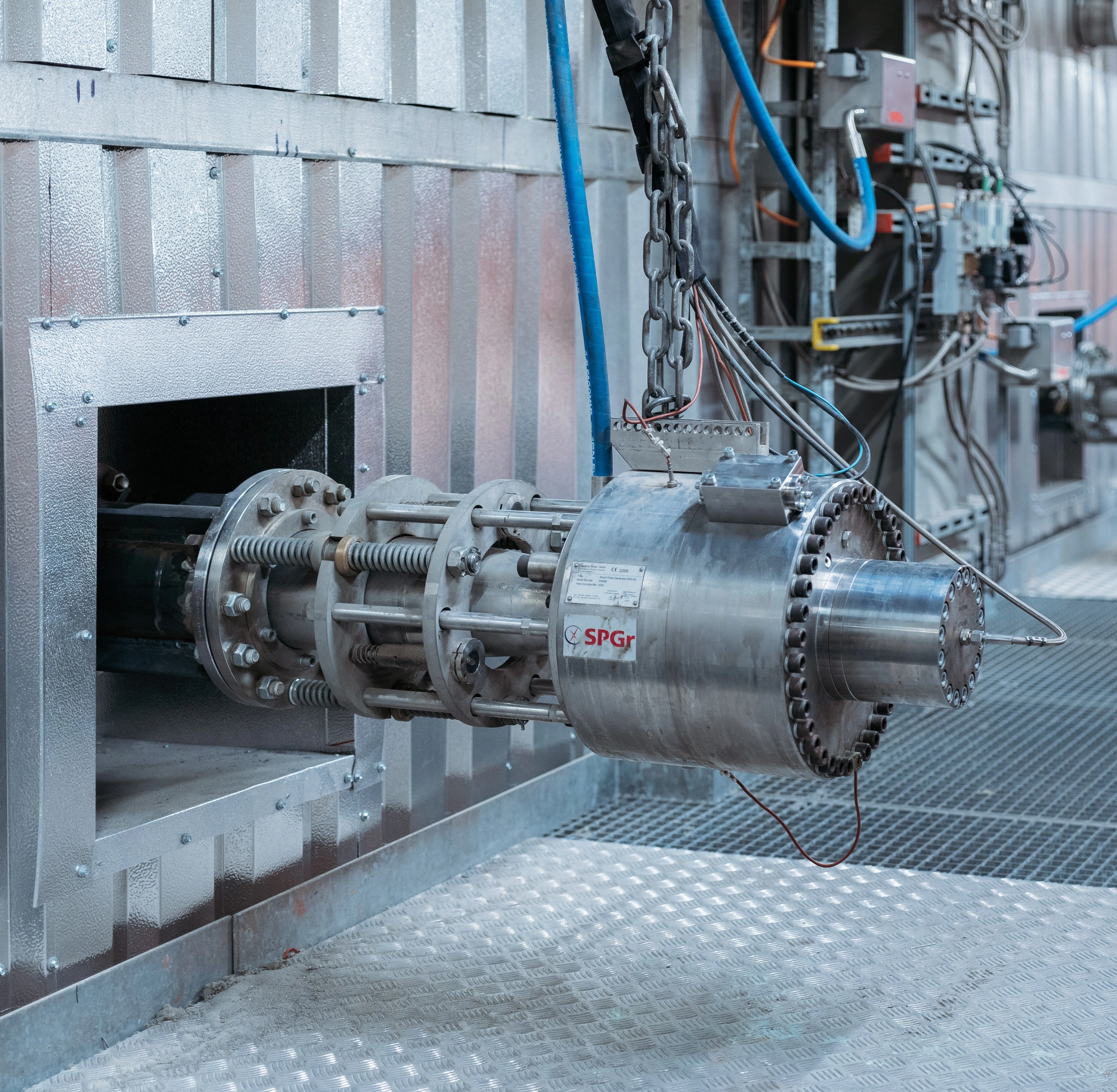

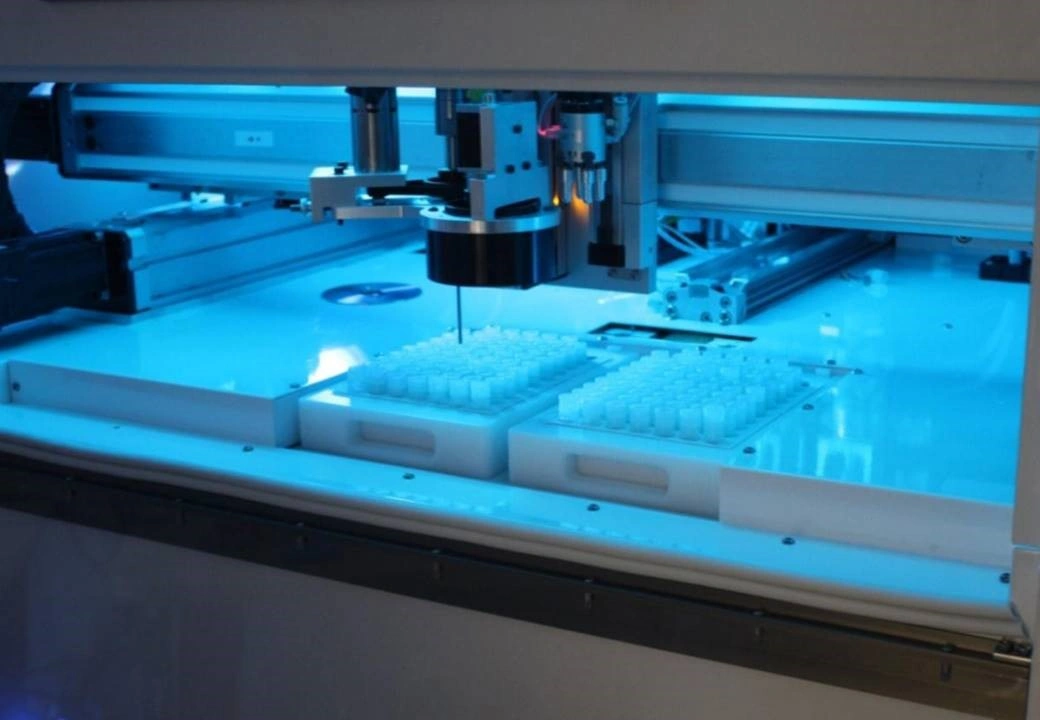

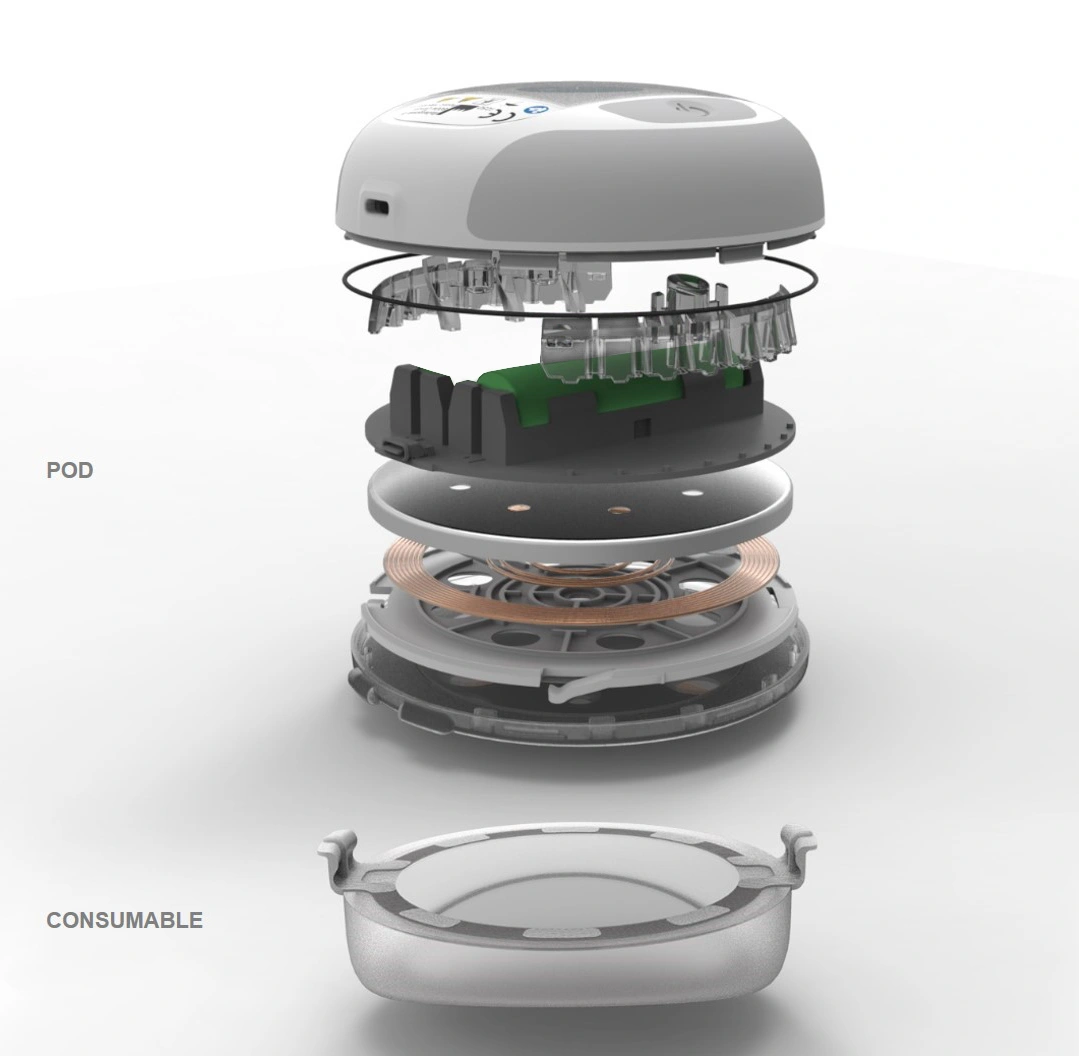

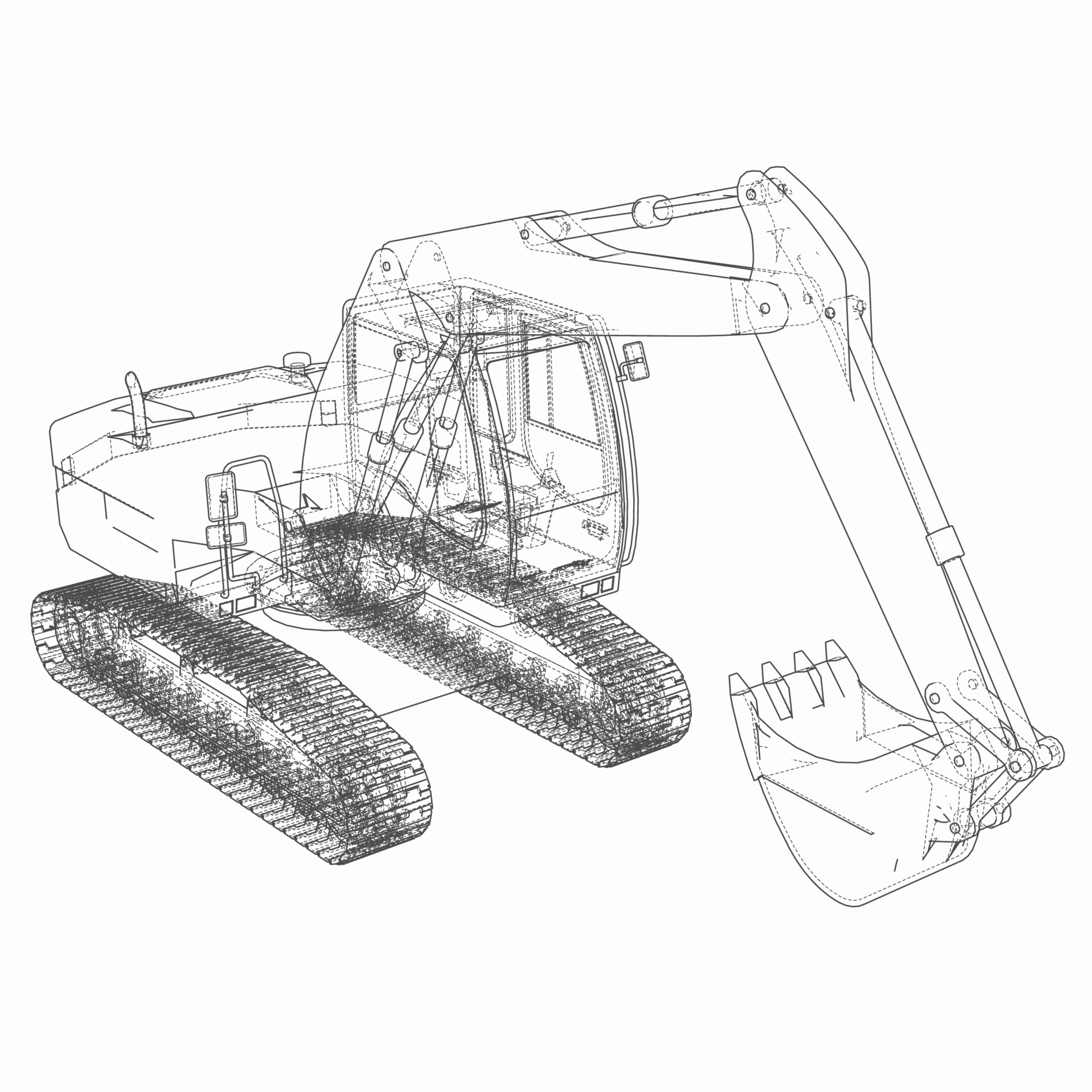

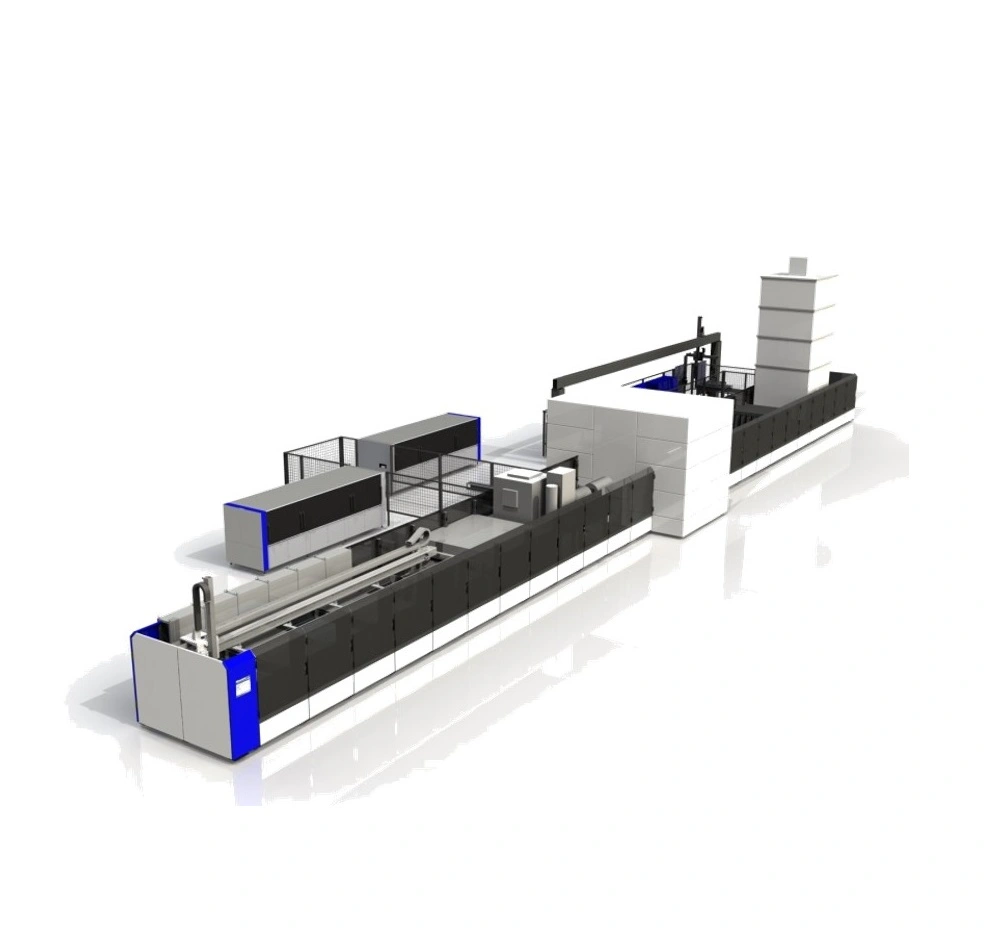

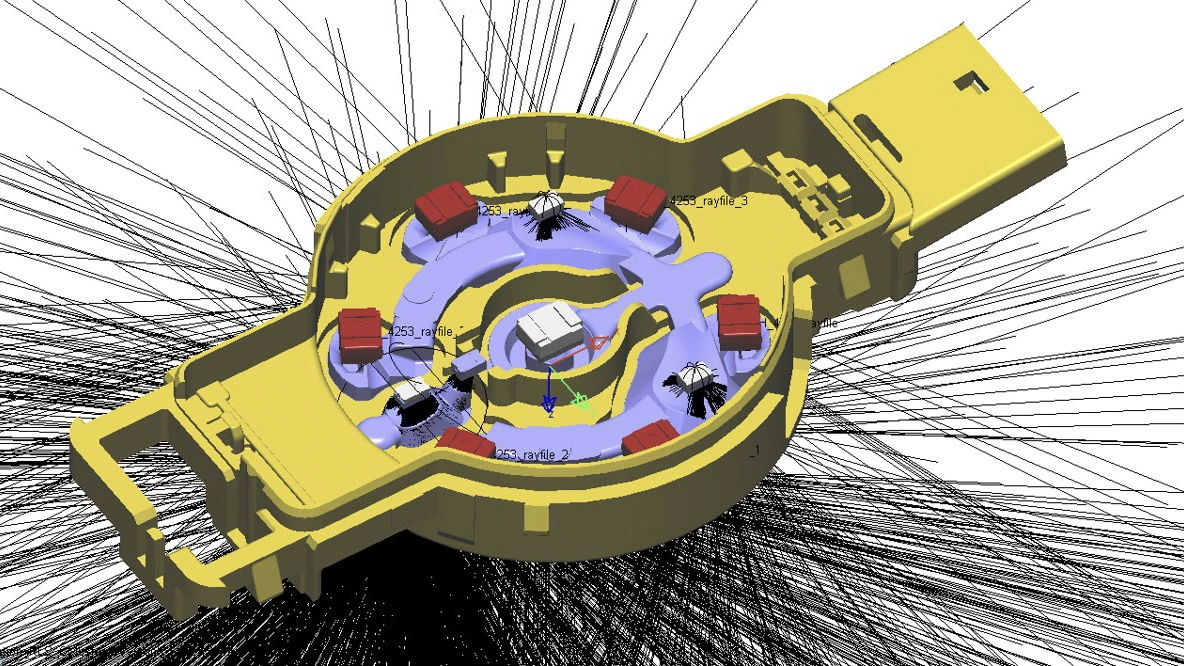

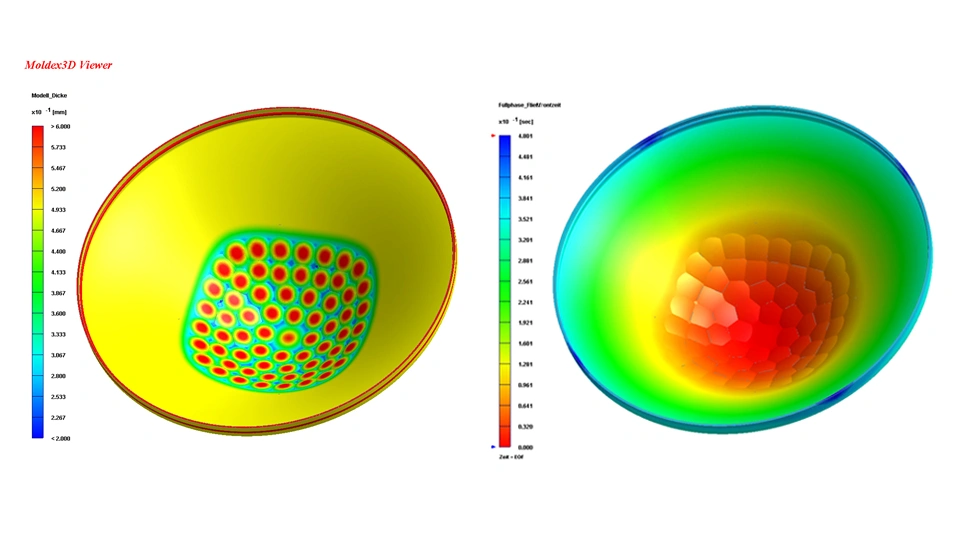

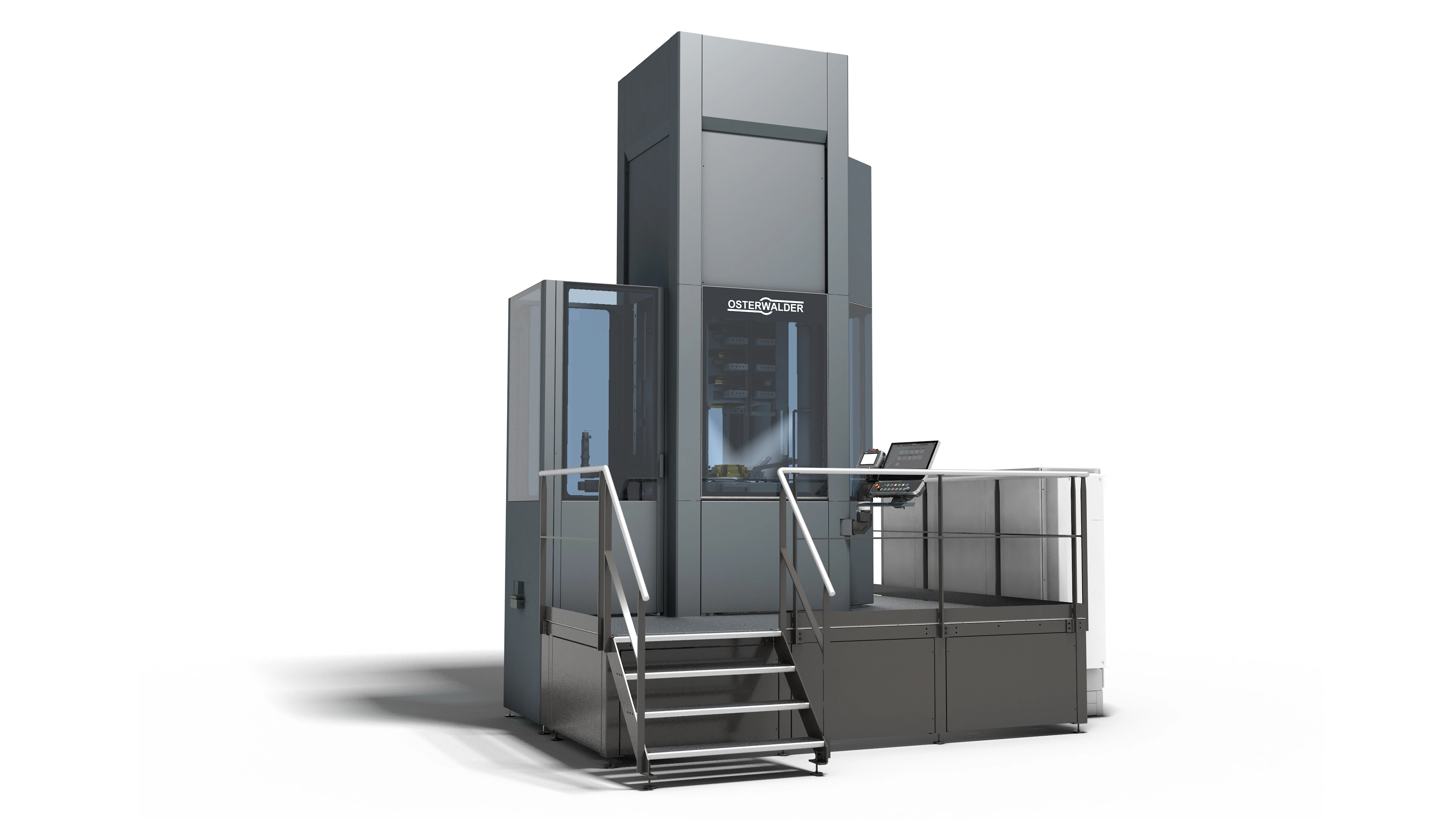

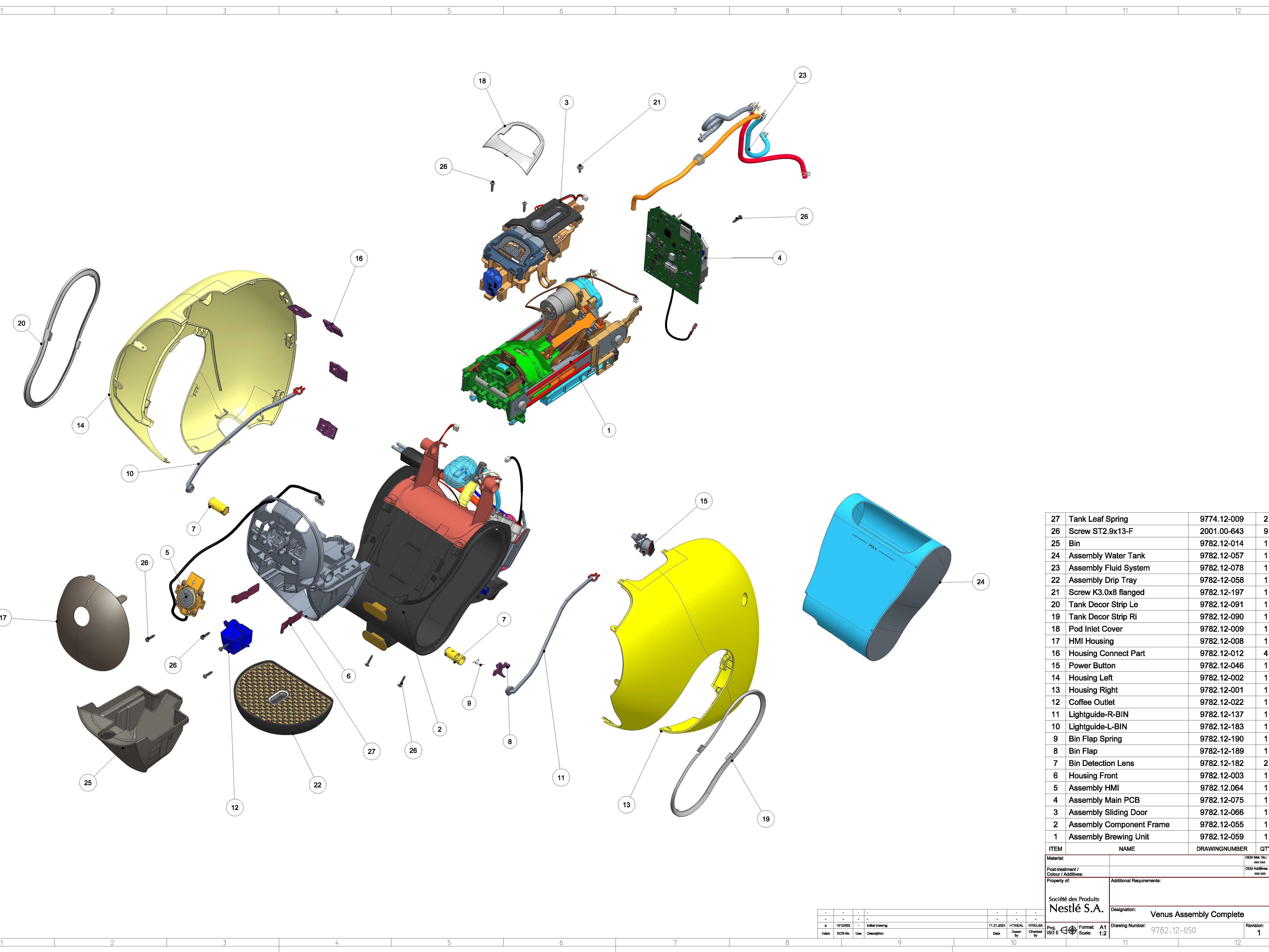

In the detailed design of a product, our specialists deal with the integration of verified subsystems into an overall system that can be manufactured without errors. Specifically, this requires detailed knowledge and skills in the areas of mechanical development (CAD), software development, electronics development, and production. Depending on the system and requirements, complementary know-how must be available in other technologies such as plastics engineering, optics or fluid mechanics and many more. By combining this knowledge, we achieve the optimal result for an overall product for you with regard to design, construction, and software.

Through the targeted use of various methods such as FMEA, DFMA, Robust Design, FEM, tolerance analyses, UX, and many more, we ensure during detail engineering that the product can be manufactured with optimum quality and functionality at the lowest possible cost. This also includes testing individual functions or assemblies using appropriate prototypes and setups, if required.

In addition, detail engineering can only succeed if proven processes are applied and control and coordination are optimally organized between all parties involved. We pay particular attention to this. This is also important because it is the only way to ensure that the needs of engineering, industrial design, production, after-sales and quality assurance are adequately taken into account.

Core services

Product development &

detailed design

detailed design

- Requirements management

- Quality engineering in development

- FMEA

- DFMA

- Tolerance analysis

- Design to cost

- Test planning

- DOE

- Test definition

- Data acquisition & processing

- Reliability engineering

- System understanding

- Physical modeling of mechanical, thermal, hydraulic, and pneumatic processes

Our Further Services

Services | Industrialization

Design Transfer

Services | Industrialization

Design Verification

Services | Industrialization

Experimental Verification, Testing, and Proof of performance

Services | Product Development

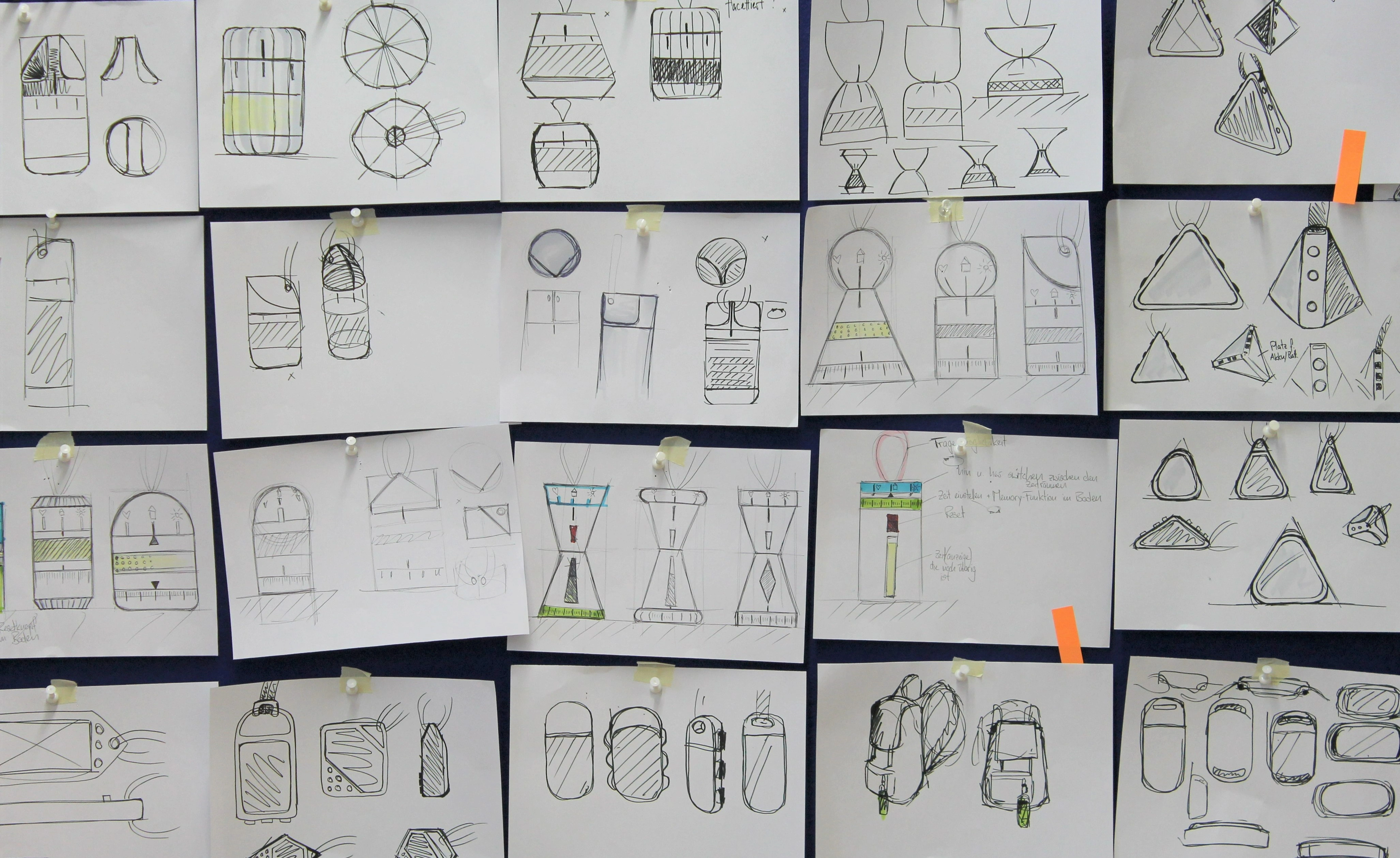

Idea Finding & Conception

Services | Product Development

Industrial- & UX-Design

Services | Ideation

Innovation Pre-Projects

Services | Technology Development

Predevelopment

Services | Ideation

Product Vision & Scouting

Services | Product Development

Project Management

Services | Product Development

Software Development

Services | Technology Development

Research, Simulation & Feasibility Analysis

Services | Sustainability

Sustainability Engineering

Services | Product Development