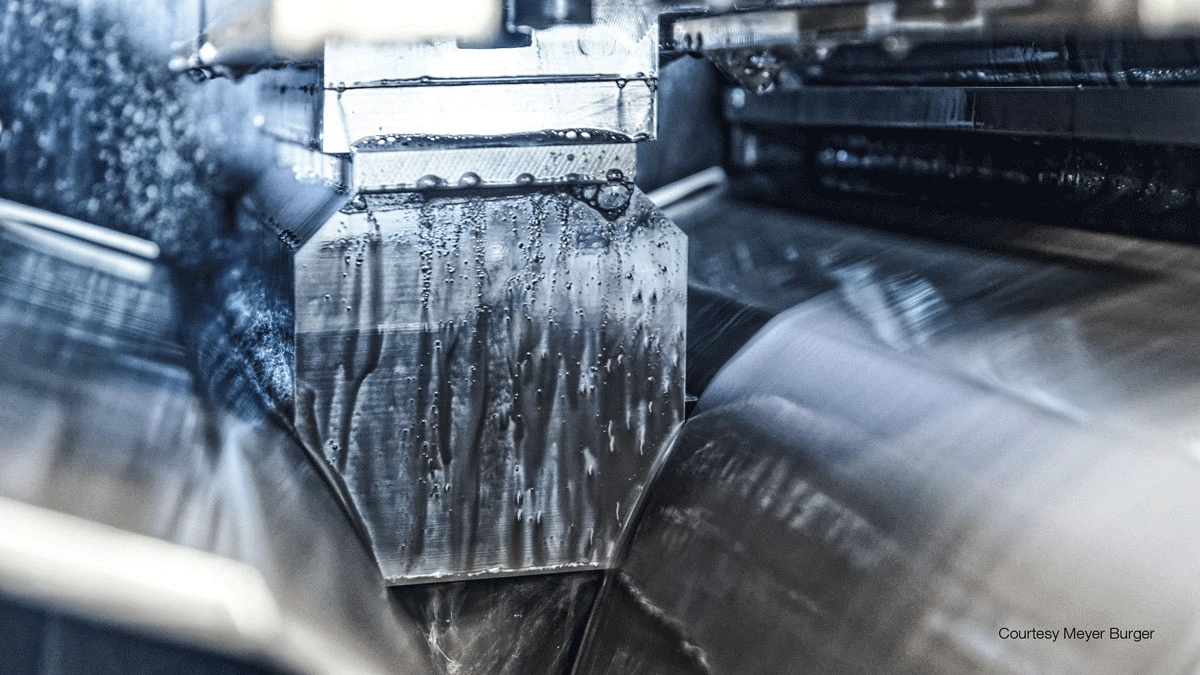

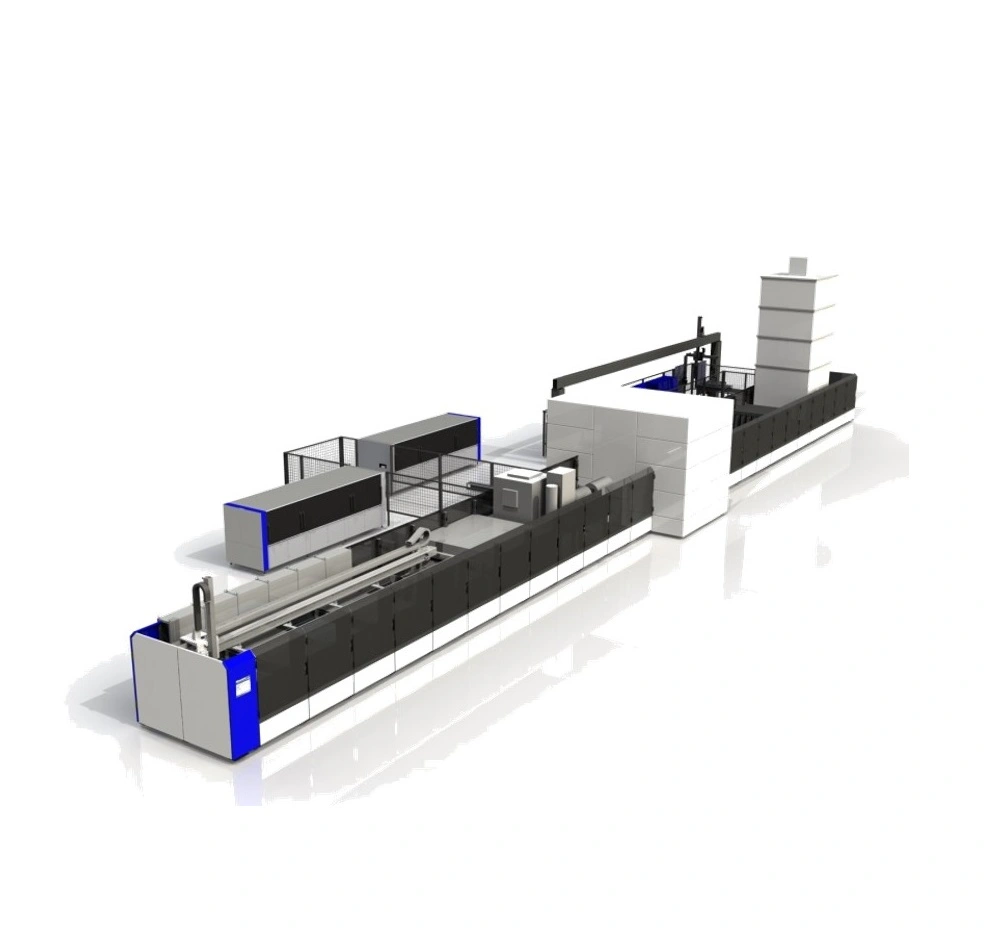

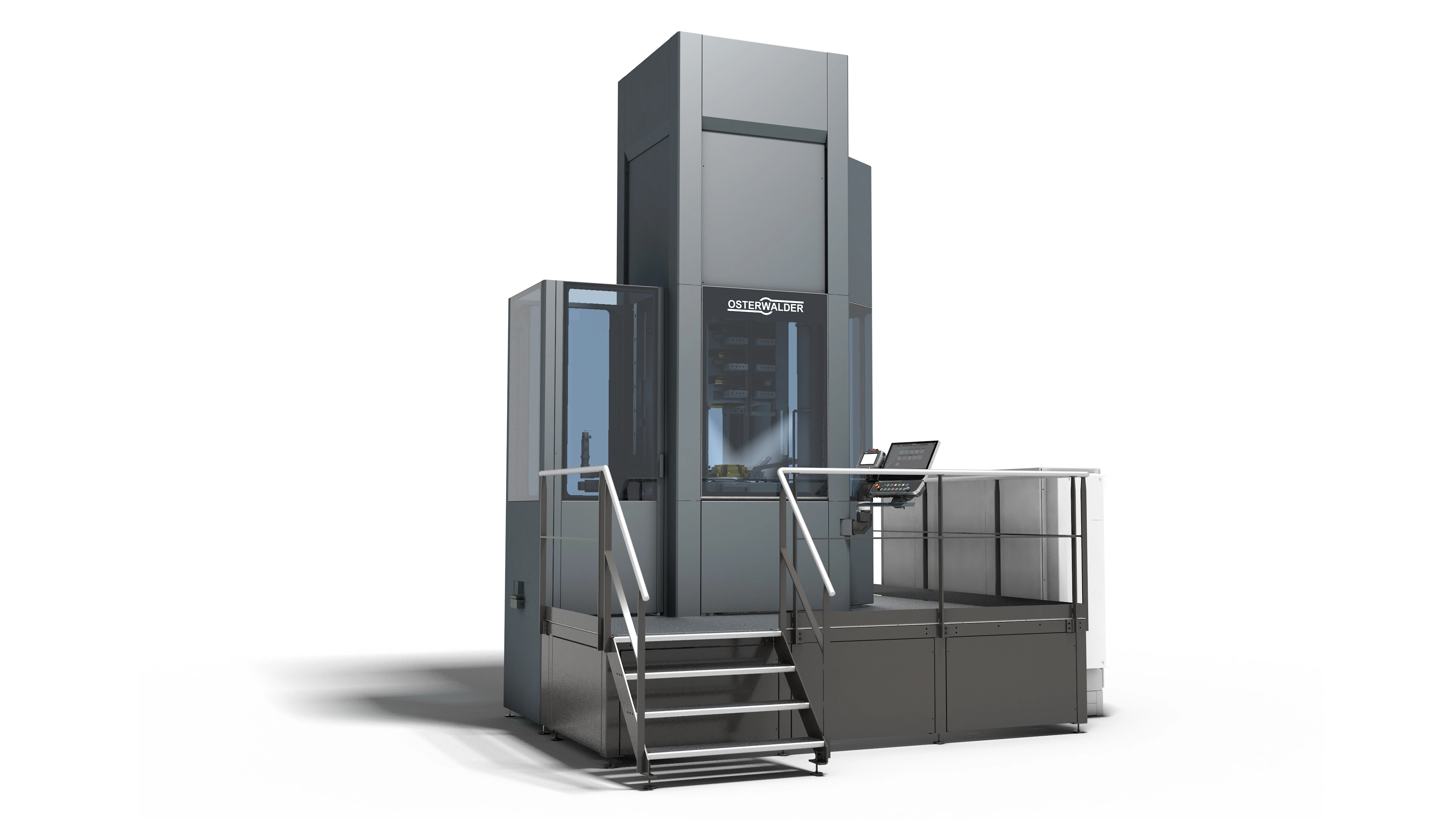

With its DW288, Meyer Burger launched the world's first machine developed exclusively for the purpose of slicing silicon bricks using diamond wire technology. The saw is capable of exploiting the advantages of this pioneering wafer production technique like no other wire saw on the market. Wire saws slice silicon bricks into individual wafers during wafer production for the photovoltaic and semiconductor industries. Slicing using diamond wire technology is proving to be a promising alternative to the conventional method, which uses slurry, a mixture of oil and silicon carbide. Not only does this approach ensure maximum material utilization, diamond wire slicing also produces monocrystalline wafers at the lowest-possible cost, in top quality and using an eco-friendly process. Since Meyer Burger was eager to get a machine platform used specifically for this method ready for series production swiftly, Helbling needed to adhere to an ambitious schedule. Helbling collaborated with Meyer Burger to develop selected modules and assemblies for the DW288, as well as high-precision adjustment and measurement tools. Depending on the specific task at hand, specialist teams were deployed with skills in the areas of mechanics, mechatronics and automation. Helbling’s experience from previous wire saw projects, take pressure off of its internal resources, meet the ambitious deadlines and get an outside perspective on the project.

Key Figures

- Max. wire speed of up to 25 m/s

- Maximum load of 620 mm

- Thin wafers (≥120 µm) / thin wire (≥100 µm core)

- Highest yield & uptime

- Lowest footprint

Our Contribution

- Idea and concept for mechanics of individual modules and setting and measurement tools

- Detailed development of complete mechanics (design and production documents in accordance with Meyer Burger design guidelines)

- Assistance with assembly and commissioning of first machine

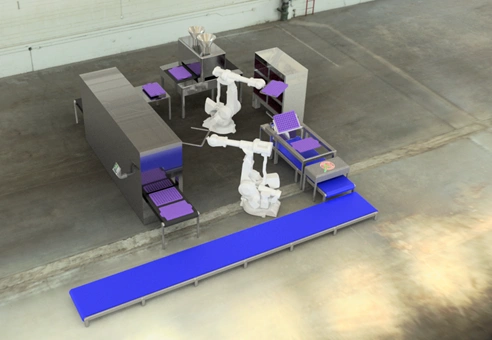

- Design of an integration solution of the single machine into a fully automated production line