Industries

Artificial Intelligences

The requirements on high-tech consumer products in the optics sector are particularly demanding. Nevertheless, the Japanese company Kubota Vision achieved a rapid and cost-efficient market launch of its “Kubota Glass™” smart glasses, which combine augmented reality and precision optics to slow myopia progression. By leveraging its expertise particularly in terms of optical design, miniaturization of opto-electronic systems, and not least industrialization, Helbling played a key role in this success.

A cure for myopia

With more than 2.6 billion people living with the condition worldwide, Myopia – or short-sightedness – is one of the most common lifestyle-related diseases. The global prevalence of myopia is increasing, and the World Health Organization (WHO) predicts that 50 percent of the world’s population will have myopia by 2050. Today, up to 80 percent of children in Asia already suffer from the effects of myopia. This trend is highly concerning because the excessive eye elongation associated with myopia significantly increases the risk of severe, sight-threatening complications later in life. These include the chronic eye disease glaucoma, cataracts, and myopic maculopathies, which affect the macula – i.e. the crucial part at the center of the retina responsible for sharp, detailed vision – and even retinal detachments.

To address this challenge, Kubota Vision, led by its founder Ryo Kubota, MD, PhD, Chairman, President, and CEO, developed an innovative spectacle lens-based phototherapy designed to slow myopia progression and reduce the risk of these complications. Unlike conventional solutions, Kubota Glass™ leverages augmented reality to create a Custom Visual Environment for myopia management. It incorporates:

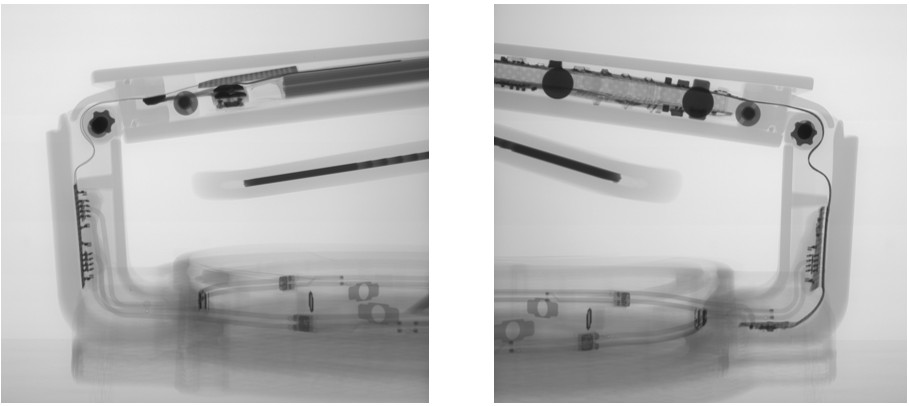

- a miniaturized opto-electronic unit that includes white light-producing micro-LEDs, a power source and a control mechanism to actuate the micro-LEDs

- miniature micro-lenses and paracentral mirrors to project a defocused stimulus onto the retinal periphery

- a refractive passive optical lens adapted to the eyes of the patient

Step 1: Identifying critical functions to reduce time to market

As a partner of Kubota Vision, Helbling assumed highly specialized product development tasks in this project, as it had done previously. Helbling’s experts performed optical calculations and ray-tracing simulations to translate the optical specifications into precise mechanical dimensions. For this, they used Zemax, an optical design and simulation software for designing and analyzing lenses and optical systems. Based on the data determined using Zemax, Helbling’s experts were able to develop a tolerance analysis model, which serves to ensure that the optical components can be manufactured and assembled reliably. The tolerances were then provided to Helbling’s manufacturing partners to produce and verify the individual components and build them into the finished optical systems that meet the requirements for effective myopia therapy.

A key factor in the rapid and successful market launch was Helbling’s methodology of identifying critical manufacturing processes at an early project stage. This allowed the team to de-risk these processes while continuing product development in parallel, significantly accelerating the whole product development timeline.

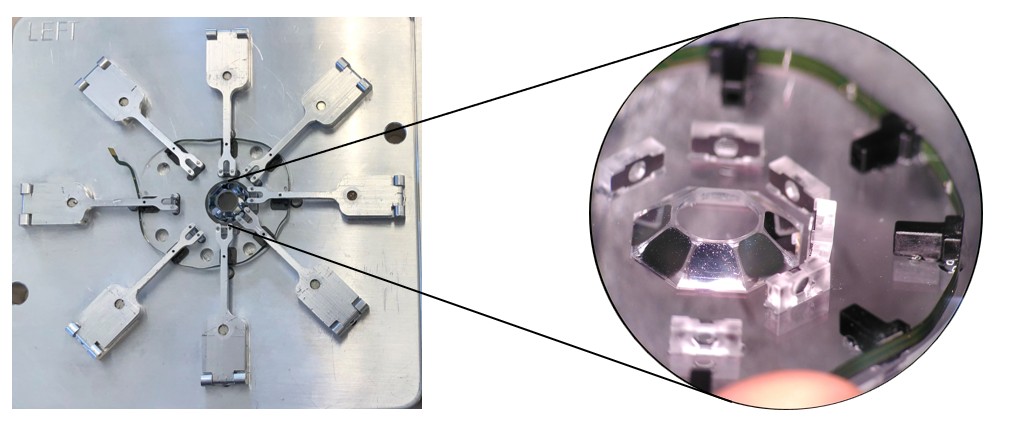

Example: Critical manufacturing of the central mirror

One example of this approach is the manufacturing of the central mirrors, which requires highly precise production methods to achieve sub-micrometer flatness for accurate, distortion-free projection of the stimulus onto the eye. In the final product design, the mirrors are specified to be made out of plastic. To accelerate the project, Helbling chose to manufacture the first 100 devices with diamond-machined aluminum mirrors, which enabled pre-clinical studies to be conducted early and allowed product development and industrialization processes to take place in parallel. The results of these studies provided stakeholders with valuable insights into design and usability issues, in the process facilitating optimization of therapeutic efficacy by testing different configurations on patients.

Meanwhile, Helbling’s industrialization engineers worked in close collaboration with the precision optics molding partner of choice to establish, test, and optimize the injection-molding and coating processes. This critical step made it possible to produce the central mirrors cost-effectively and launch an economically viable product on the market.

Step 2: Reducing product costs through design adaptations, knowledge transfer and new tools

The Kubota Glass™ is manufactured across three continents by partners who excel in their respective fields. Helbling initiated collaboration within this partner network early in the design phase. Open communications led to design adaptations being agreed between the partners to streamline manufacturing and reduce the product costs.

First, minor changes were introduced to enable semi-automated assembly of optical components, improving efficiency and scalability. Second, manual assembly steps were successfully relocated from Europe to Southeast Asia, with Helbling playing a key role in ensuring a smooth knowledge transfer. Finally, yield was significantly enhanced by developing production tools that minimized glue contamination on optical parts and ensured precise alignment during assembly.

Summary: Know-how and systematic methods drive efficient high-tech product launches

The combined efforts in relation to de-risking and scalability demonstrate Helbling’s major contribution to cost optimization and manufacturing excellence. In this context, it is essential that Helbling’s teams bring together specialists with expertise in optical and mechanical engineering. These teams also possess long-standing experience and deep knowledge of industrialization processes in the high-tech sector. As a result, the Kubota Glasses™ were brought to market following a tightly scheduled and efficient development process. With its interdisciplinary teams that leverage tried-and-tested approaches on a cross-sector basis, Helbling also supports other companies operating outside of the medical or optics sectors to realize similar projects.

Authors: Christian Tâche, Pascal Loser

Main Image: Kubota Vision